20190714 TerraHertz http://everist.org NobLog home Updated 20190807

Well, it's been nearly two years since I got anything done on a primary project, the vacuum chamber system. The last progress on that was in Oct 2017, buying a big old lathe, needed to machine some large diameter rings. That purchase itself had blown up into a tangle of diversions. Contagious apparently, since after that some kind of 'diversionary curse' set in.

The few articles I've posted since then mention the foremost culprits for my lack of progress — the large UPS, the Searchlight, involvement with the ACMS (an ongoing train of events), beginning some writeups of my early Apple II works (to be a series), and the Spectrum Analyzer buy that went way off the rails. (And is still.) There were other major things (and still uncompleted articles about some), but lots and lots of minor time pests. This is about them.

I know, I'm the real cause, due to poor choices. Here's more evidence of guilt. Or something. Of someone. A diary-like chronology of recent pesky time-weavils, individually small but nonetheless nibbled away all available time rations so far this year. An illustration of typical circumstances around here. I should lay out some time-weavil baits, see if I can eradicate the little buggers.

Today I picked up another microwave oven, inverter type, from a kerb. Found it before the cord-cutters got to it. It didn't work, but took only a few minutes to fix. The fault is due to really crappy design, and this is the second unit I've found with the exact same fault. Bad enough to mention in eevblog repair category. Both the fault and fix are purely mechanical.

It's a Panasonic model NN-ST641W, 1100 Watts. An inverter type, ie no heavy HV transformer. I like these.

Symptoms: The timer/clock runs, buttons work. But when you tell it to run there's no fan, no microwave power. The relay on the control board closes OK when it tries to run.

|

|

|

|

|

Inspecting the three microswitches on the door interlock assembly, one seems to have no means for the switch to operate when the door is closed. Because a small piece of plastic that's supposed to be there between the door latch prong and the microswitch button, is missing.

It used a thin plastic 'spring', and this broke off. The plastic bit was found rattling around in the case, but there's no possibility of gluing the very thin 'spring' fracture.

Solution: Use a short length of springy stainless steel, excess from a metal wiretie, to make a replacement for the plastic bit.

The secretary of the ACMS and I drove up to Gosford area in my car, to pick up a huge instrument being donated to the ACMS. It's a very unusual magnetic 'tape' playback machine. One unique feature is that the 'tape' was sheets of magnetic film, nearly square. They held many channels of short time duration recordings, from explosive geo-exploration seismic instruments. The sheets of mag-film are mounted on drums, then spun, under a row of many pickup heads.

It's a pity it's so wrecked. The machine has been sitting under a leaky tarp in an open carport for years, It's VERY degraded. I'd call it utterly ruined. But it still looks impressive. Like something out of an old Dr Who movie.

Supposedly it weighs around 300 Kg, but I don't believe that. I think it's a lot more. The challenges for the day were to get it onto my trailer at pickup, and off again at destination. I had brought a bunch of rope gear, a chainblock winch, the bolt-on ramp for the trailer, crowbars, big wooden wedges, etc.

At the pickup address it was tricky enough. The machine is on castors and can be rolled easily on a flat hard level surface. But it's only just narrow enough for the castors to fit along the very edges of my narrow trailer ramp. Having it fall off would be bad. With the weight and awkwardness, even with four people, manhandling it up the ramp was out of the question. Way too dangerous, even if it had been physically possible. So I improvised 'side rails' from some bits of wood and bricks, then used the winch to drag it up the ramp while constrained by the rails. Crowbar and wedges to get it onto the bottom lip of the ramp initially.

Once set up, that worked well. I tied it down very securely on the trailer, soaked my head in cold water to recover from strenuous work in full sun on this very hot day, then we were off back to Sydney. Had been working too fast to take any photos there.

|

|

|

|

|

Things were more difficult at the destination. It had to be unloaded to an under cover car park, but with no one there but myself and the ACMS Secretary. Who is a lot older than me, and has a very bad back. So it was effectively just me. And this time there were no wooden posts available to form those guide rails. All I could find was a pile of softwood pallets, and one milk crate. But I keep a bow saw as standard equipment in the car! So could cut up pallets into whatever I wanted.

The technique I picked was to attach the trailer ramp, secure the recorder with a rope belay, chock the trailer ends with pallet bits so it couldn't tilt much either way, unhitch it from the car, then with crowbar and varying chocks, tilt the trailer up to match the slope of the ramp. Then build side platforms to the ramp so the recorder couldn't fall over sideways if it did deviate off the side of the ramp (which it did.) Then use the rope with figure-8 belay to let the recorder slide down under its own weight.

This all worked well, with a heavy thunderstorm and deluge beginning right in the middle of activity for added excitement. Some bags and tools had to be quickly rescued from a flash flood in the carpark, but fortunately the work area was under cover.

One of the original aims in starting this NobLog thing, was to write up a series of my early life's technical works. This still hadn't happened. Writing Data in the Holes had reminded me of this omission. Side projects (now with added ACMS flavor) are always going to consume much of my time, but I needed a starting point for getting back on the intended track. So wrote Missing the Wave.

|

|

The difficulty is proportional time allocation. Urgent relic stabilizations like HP9830A and PDP-8/S chewed a lot, so with the new year approaching I turned again towards the 'early works' project.

Many of which are Apple II related and have all their code still on my old Apple II floppies, hence beginning the 20190106 A Highly Hacked Apple II article. That machine has to be working if I'm to recover this old code, and proceed with many of the intended stories.

20190109 The Bent Spectrum Analyzer. Offer not accepted.

20190114 Kittens born! A major but very enjoyable consumer of time, indefinitely.

20190120 Bought Spectrum Analyzer. Unwittingly letting loose a Time-Weavils infestation.

|

|

Now this is a waste of space, and awfully heavy to move around. I keep some old CRT screens for retro-computing purposes, but not this hulking thing. So the PCBs will join the pile of 'potential components' boards, the case will be cut up and go in the recycling bin.

As for the CRT... it's de-vacuumed by punching a small hole in the EHT nipple, then cutting off the electron gun neck. I want to make an attempt at cutting the glass front face off from the rest of the tube, since it's an enormously thick flat plate of glass. Might be useful as a vacuum system view port, if it's possible to cut. Maybe with masonry disks and water cooling? I have a huge brick cutting machine, just not currently set up.

As for the CRT... it's de-vacuumed by punching a small hole in the EHT nipple, then cutting off the electron gun neck. I want to make an attempt at cutting the glass front face off from the rest of the tube, since it's an enormously thick flat plate of glass. Might be useful as a vacuum system view port, if it's possible to cut. Maybe with masonry disks and water cooling? I have a huge brick cutting machine, just not currently set up.

2019 Feb 2nd: resoldering those clip leads. 3rd: Kittens' first adventure outside, and couple of old Bay Networks ethernet switches. 5th: The Spectrum Analyzer arrives. 6th: Trying my 'new' backup EOS 40D with a working lens. 7th: Bulk cleaning and erasing some EPROMs for the Apple II.

Back in 2016 I'd acquired a LAB 522 Labornetzgerat regulated power supply. Dual 0-30V/0-2A. Slighty the worse for wear, but it had cleaned up nicely and works.

Back in 2016 I'd acquired a LAB 522 Labornetzgerat regulated power supply. Dual 0-30V/0-2A. Slighty the worse for wear, but it had cleaned up nicely and works.Now another one came up on Ebay, from a seller a convenient drive from my place. It looks a bit rough, but I bought it.

Turned out to have been heavily used at a TAFE and was in more worn condition than the ebay photos had shown.

|

|

|

|

The meter plastics were yellowed, and there's a very dirty looking condensate of some kind on the inside of all the meter glass covers.

One of the meter bakelite rear bodies was cracked.

The dirty glass and cracked body were easy enough to fix. The yellowing I can live with. There was also corrosion and flaking paint plus a stencilled TAFE logo painted on the top cover, a rough hole cut in the bottom cover, and rusty steel TO3 transistors on the back. The top cover would be the next job, but the paint resisted removal by sanding. Looks like it would require chemical paint stripper. At that point I put the thing aside. For a few months.

|

|

|

|

|

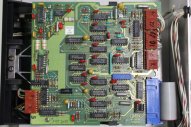

Whether it's dead or working I don't care. Just wanted to open it up and gawk. I've never had experience with RF design, especially the GHz ranges, so to me the weird circuit techniques used in this stuff are close to magic. Very fascinating magic. Someday I'd like to gain such skills, but for now I simply enjoy admiring PCBs like this, for a few superficial insights. I've never had the kinds of test gear needed for such work, though the recent spectrum analyzer buy could be considered a first step. Sadly it only goes to 2.9GHz, while these LNBs involve up around 13 GHz.

Incidentally, here's the datasheet for the ZNBG3210 control IC used there. Comparing that to the PCB layout, you can work out the purpose of most of the structures.

2019 Feb 9th: Apple II testing & goofs 11th: An old Alcatel-Lucent 1642EMC "STM 1 Multi-Service Edge Multiplexer". 13th: Opening the Spectrum Analyzer. 14th: That fake anti-static mat. 15th: Stubborn grub screw. 16th: A little Urbex.

A neighbor friend had picked up some industrial scrap, to take to the metal recyclers. I'd noticed it on his trailer, and realized there were several things there I could use. Made an offer, he accepted. And so, today I had some production line equipment from a candle maker, to strip down. The main things I wanted were:

|

|

|

|

|

|

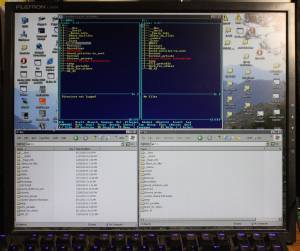

Arrgh. Hard disks. Few things underline the fundamental inadequacy of contemporary operating systems and filesystems, than the gap between relentlessly increasing storage capacity, and the (in)ability of software systems to efficiently and reliably manipulate such volumes of data. Microsoft hasn't helped with their inane 'My Documents' concept, and background disk content indexing services that make your system act like its demonically posessed (if you don't disable them.)

As for making backups and transfers, in the Terabyte storage size and up... the standard OS tools (in Windows) just fall on their faces. Even the disk format routines are painful.

But it's not my intent here to go into that whole mess. Just to mention that my main work drive was a mere 600 GB, and was becoming very close to full. I'd bought a couple of 3.5" 1 TB new drives, and needed to migrate. Also in future to be doing rotating backups, to some 5.25" 1 TB drives in an external USB dock.

The problem is the logistics, and time it takes. Everything is flakey and takes so long. I tried formatting the new drives in the external USB dock. The device claimed it worked, but it hadn't. Could only format them actually plugged into the PC. Then the transfer... No point boring with details, but the best means I have is by using an old utility called ZtreeWin. Originally an ancient DOS tool called XtreeGold, updated to work in Windows. Its main advantages being dual window, visible progress display, and 'just does it' unlike MS Windows File Explorer which will find any excuse to stall and fail to complete a large operation. Without telling you where it was up to.

The problem is the logistics, and time it takes. Everything is flakey and takes so long. I tried formatting the new drives in the external USB dock. The device claimed it worked, but it hadn't. Could only format them actually plugged into the PC. Then the transfer... No point boring with details, but the best means I have is by using an old utility called ZtreeWin. Originally an ancient DOS tool called XtreeGold, updated to work in Windows. Its main advantages being dual window, visible progress display, and 'just does it' unlike MS Windows File Explorer which will find any excuse to stall and fail to complete a large operation. Without telling you where it was up to.

Anyway, it took all day.

|

|

|

|

|

|

1, 2. Feb 25th: Preparing for some car body work. I took out interior trim, to cut down the cost of professional repair of some rust along the roof rim on one side. Years ago I overloaded a roof rack, cracked the seal along that rim. Water got into the metalwork, starting rust. I also want to mount some decent LED lighting in the roof interior trim, for car camping. Dim filament bulbs are dim.

3 - 6. Feb 28th: I'd cleared out some junk from under my mum's house. Among them two old hollow core doors that were delaminating as the aged glue failed, so they're no use other than firewood. Despite their nostalgic value to me. Because they were my desk/workbench through my early teens. (Until I built myself a more solid bench.) These bring back a lot of memories.

4: That's where my small, first bench vice was attached. I still have it but it's a toy, so is left packed away.

5: I was 17 when I made those pencil marks. They are a layout guide for a drawn-copper wire sculpture I made, as a gift for my first girlfriend. See The Old Cable.

6: Well, that's all long ago, and now these doors are falling apart. Here stripping the few useful bits of real wood out. The rest will be burned.

|

|

|

|

|

|

My old white 1993 Subaru was the last model before they switched to an engine management computer. For multiple reasons I flatly refuse to drive a car with software in the control loop. So I'll keep my car going as long as possible. Serendipity gives me a little assistance with that, as I've twice been given used cars that are almost identical models to mine. This green Subaru is the second one, and here was still intact. It was given (well not counting $100 for the 4 virtually brand new tires and brake pads, since transferred to my car) because it has bad rust around the windscreen. Otherwise runs nicely. I'm keeping it as spare parts; weather and leaf-mulch proofed with lots of silastic and rubber sheeting. It's now used as storage of many parts from the other car. That one I cut up the body, keeping only the engine and other bits.

During the ACMS flight from their terminated-lease storage space in Villawood, July 2018, quite a lot of the items had gone to a temporarily donated storage space in Milperra.

During the ACMS flight from their terminated-lease storage space in Villawood, July 2018, quite a lot of the items had gone to a temporarily donated storage space in Milperra.

In March 2019, that space had to be vacated.

That was a busy day, packing a full length shipping container with most of the items. Leaving 11 pallets and half a dozen larger items that wouldn't fit and had to be dealt with later.

In which I learnt that climbing around on top of equipment racks, in a steel shipping container, in full summer midday sun, is extremely hot.

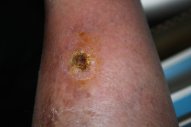

Also when picking a wooden pallet off that pile barely visible in the photo (behind the foreground plastic-wrapped rack), I'd mildly dinged my right shin. Slight blood-blister, barely broke the skin. Insignificant at the time, but played a part in later 'diversions.'

Also when picking a wooden pallet off that pile barely visible in the photo (behind the foreground plastic-wrapped rack), I'd mildly dinged my right shin. Slight blood-blister, barely broke the skin. Insignificant at the time, but played a part in later 'diversions.'

By the evening it looked like this, before applying antiseptic. Over the next couple of weeks it healed well, till the scab seemed about ready to fall off.

Why did I mention this? You'll see.

This was a kerb toss, found on the way to my mum's place one Monday to do her weekly shopping. Grabbed because it was the largest tossed LCD TV I've yet seen. Didn't expect it to work, just curious. I certainly don't have sufficient space anywhere to actually use this, even if it did work. Besides, it's missing the remote control, and looking at the online manual (Kogan KALED65UHDZB) it really needs it. These things get thinner and thinner, and it's interesting to see how they achieve that. This one is so thin, it bends under its own weight if not mounted upright.

|

|

|

|

|

|

|

|

1st Row

1. Wow, it's 3D! No, just a couple of my cats investigating.

2. The mains cord has an amusing type of damage. A series of chops along the cable. I suspect someone was playing with a drone indoors, and these are prop cuts. I cut out the bad length, spliced and taped the plug back on for testing.

3. In the back, there's very little. One power supply board (under a black cover in the pic), a processor board (right), a small interface to the LCD flat cables (center), an IR interface (bottom left), and a woggle stick for control interface (bottom right.)

4. It was dead. The backlight illuminates, all power rails are good, but the glass is cracked under the plastic film and there's no sign of image life. So I stripped it. I now have a lifetime supply of useful light diffuser films. Or do I? An idea occurs to me...

2nd Row

1, 2. Something I need is a kind of backlighted flat white bright illuminator. Like one of those X-ray film light panels in hospitals. I've tried hacking a couple of smaller dead LCD screens, but so far there's always been some obstacle.

Here's how they make it so thin. The illuminator is a narrow strip of white LEDs, shining into the edge of a plastic sheet just 2mm thick. Plus a few other paper-thin reflector and diffuser sheets. It's easy to power it up on the bench, and it's extremely bright. Literally painful to look at.

3, 4. Hmm, it's actually two separate and identical LED strips glued to one long aluminium pressed heatsink strip. With about a 1mm gap between the LED-strip ends in the middle. Just enough to fit a hack saw blade. So it (the aluminium backing heatsink) was just asking to be cut in half. The halves still work. So now I can make a light panel of more convenient size, with illumination from opposite edges. Just need to cut those optical sheets. Without cracking the plastic, and with reasonably polished edges. And improvise a frame.

Of course I didn't have time just then to do it. So the bits are put aside, waiting.

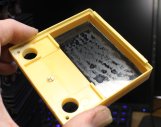

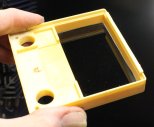

Usually it's my cats bringing in dead mice. This time I found a wireless one, with its underbelly cruelly ripped out. The battery cover missing, to be precise. The mouse was in a box of stuff discarded by a computer store in Oatley. Sensibly tossed, since such mice are under $20 new. This one is a Microsoft wireless mobile mouse 1000, which makes it oooold too; around 2012.

But it works. And I could use another wireless mouse, for a logic analyzer. So more for the construction challenge than necessity, here's a quick hack to make a battery door for it.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

It works nicely. Though is far less cute than these mice.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A favorite spot of mine.

|

|

|

|

This Sunday morning I found one of those turnbuckles and length of rusty wire on the back lawn. Huh?

Looking up at the antenna mast, realised a guy wire had rusted completely through. The turnbuckle has a hook on the eye-bolt end so it had just fallen off. Lucky it fell to the ground and I noticed it. Because it left the antenna mast with just two cables but still standing. Even a slight wind would blow it over. An urgent repair. Went to the hardware store, where I knew they would now have nice stainless steel cable, clamps and turnbuckles. It's a two storey house, needs a tall ladder to get up there, but that's OK.

There was a slight rigmarole, because originally I'd fixed the cables to the mast by drilling small holes in the mast and making thin tubular brass sleeves to protect the cables from the sharp hole edges. Of course the rusting cable had expanded and locked itself into the sleeves. So I had to make new ones, and getting the old ones out of the mast was a bit of a bother too. Anyway, all finished just on dusk.

|

|

|

|

|

So trivial, right? You are surely wondering why did I even mention this.

Because, while handling that broken multi-stranded wire, one of the rusty strand ends had stuck into a finger. Slightly; at the time I thought nothing of it, just pulled it out. Didn't even bleed. And then...

Remember that banged shin from two weeks ago? By now it was almost healed. Healthy, no inflamation, scab about ready to peel off. I'd been ignoring it. Never took any more pics, because no reason to.

By Monday afternoon I noticed a little reddening starting around that nearly healed shin scab. Went and did my mum's chores as usual on Mondays. Got home a bit before midnight, continued some work on a software project related to the problems printing that PDF service manual for the spectrum analyzer. Which turned into an all-nighter. In the small hours of Tuesday AM I ordered a couple of PDF internals textbooks:

PDF Explained — John Whitington, and Developing with PDF — Leonard Rosenthol.

I was also obtaining (again) all the free online PDF standards documents. I'd already fetched those back in 2016, but wanted to be sure I had all now available. And did find some new ones on Adobe servers.

Staying up all night is a bad habit of mine, that usually manifests when I'm depressed about something. That whole spectrum analyzer and manuals sequence has been pretty disappointing. Made even worse by now needing to embark on a fairly major software effort (a huge diversion, which I hate), to deal with a stupid PDF (which I hate) file internal structural problem (which only exists because PDF is stupid), and because there don't seem to be any adequate PDF dissection tools available (which I know why, and some background about, and that's depressing too.) Plus all this reminds me of the circumstances of buying a dead spectrum analyzer with missing manual in the first place, and the manuals libraries disastrous closures. The latter being the worst, since it seriously impacts long term ambitions of mine. Hence my being fairly unhappy and staying up all night.

By Tuesday 16th morning I was also starting to notice a slight twinge of pain in a muscle in upper left thigh. At first I assumed it was some very minor strain, or from pressing the thigh against chair seat for too long during the all-nighter. However the shin infection started really flaring up. Becoming very red and sore to touch, spreading. As the day progressed the left upper thigh 'twinge' began getting rapidly worse too, with pain more or less mirroring the shin infection. Obviously 'similar in kind', and not good.

On Wed 17th both infection sites were getting worse quite rapidly. The R shin site becoming very visibly inflamed over an expanding area. The L thigh deep muscle getting very sore, though no visible changes on surface. Around midday I tried to see a doctor. Revesby, Panania clinics, and Dr Vij's clinic, all had no openings then or for the rest of the day. When I got home I started taking some emergency antibiotics my GP prescribed for flareups of another intermittent problem I have. One with lunch, one with a late dinner.

In the evening I noticed there is some 'leaked blood drainage' bruising on inner side of my R heel. Shows how bad the shin infection is getting.

|

If you're squeemish, better not click to enlarge the images in this sequence.

Around midday I had to drive to my mum's place to get her something from the chemist urgently. Discovered that the L upper thigh internal infection site is unavoidably pressed on by the car seat, making driving quite agonizing.

On return home, searching for an available doctor I found there is an after hours clinic in Revesby. Went there around 6:30pm. No queue, very short wait. Straight away given referral to hospital, urged to go immediately.

Initially had intended to go to Liverpool Hospital. But with the L leg making driving excruciating, I thought maybe give (closer) Bankstown Hospital a chance to redeem themselves? (I've had some bad experiences there in the past. But now thinking in pain, ha ha.) Got to BH about 8pm.

The usual story. Quick triage interview, then back to the waiting room for hours. Eventually get admitted. Blood shunt put in arm, missing vein on 1st attempt.

Seeing doctor, I explain history of the shin infection. Also that there's another even more painful site internally in L thigh, not visible. He completely ignores that one, and no one ever pays any attention to that at all for the rest of my stay.

|

|

My camera RTC shows the time then was 10:56PM. I checked next day at home and the camera RTC has the correct time. So it took BH around 3 hours to even get to examining the infection, though from the start they saw how bad it was.

Later she puts a stick-on membrane cover over it. None of this hurts at all, but that's not good really. Means all the nerves there are dead. At no point did the doctor look at the wound once the scab was removed.

Arrangements are made to send me for X-rays of the R shin site. I remind them there's another internal site in L thigh, and they add L thigh X-rays. The machine uses a very cool digital wireless imaging slab. Zero consumables cost.

To my surprise, walking to the X-ray was MUCH more painful than walking had been when I arrived there. The L thigh muscle infection has become a lot worse in those few hours.

I get told both the blood sample and X-rays were normal. Around 11:30pm they start an IV drip feed of antibiotics. I don't recall the name they said.

A while after that finished, they decide to discharge me. Given 6 pills of cephalexin 500mg, told to take 4 a day. Plus scrip for more. Told swab culture results will be up to 72 hours, see my GP 'in two days'. (They ignore that it's Thurs night before Easter weekend, so next possible GP visit will be Tuesday.) So they just assumed the IV antibiotics would work, without taking any steps to verify that they were working, and little possibility for me to do anything other than go back to hospital if it didn't work.

Got out of there around 1am. The drive home was incredibly painful. Barely possible, and I'm fairly pain resilient. It seemed to me that the thigh muscle infection site was still getting worse.

Overall, I consider this BH visit another demonstration of the place's usual poor performance. The staff are mostly great, but the organizational structure is chaotic and amnesiac. The discharge letter is the usual erroneous crap.

I went to bed, but can't sleep much. The L leg aches, almost all positions press on the sore area. And turning is very difficult when you can't use those muscles at all (without excruciating pain.)

So what is it? Can it really be from that tiny rusty wire pinprick? Maybe Tetanus? Amazing. Such a little thing, and if this was 150 years ago I'd now be dying horribly.

20190419 Friday. I slept in fitfully till around 9am. Left leg is still really sore, not so useful as a leg, so moving around is a problem. But it seems a _little_ better than last night, so hopefully the antibiotics have the upper hand. It's fairly painful to sit too. Great. Took 4 of the cephalexin over the course of the day. Both leg damage sites seems to be static, ie not getting any worse. Hopefull.

20190420 Saturday. In morning took the remaining two cephalexin from BH, and went to Panania to buy more, plus some of the same size film dressings. Different brand. Both legs now definitely improving. I'm a bit too chicken so far to remove the stick-on dressing on the shin 'hole'.

|

|

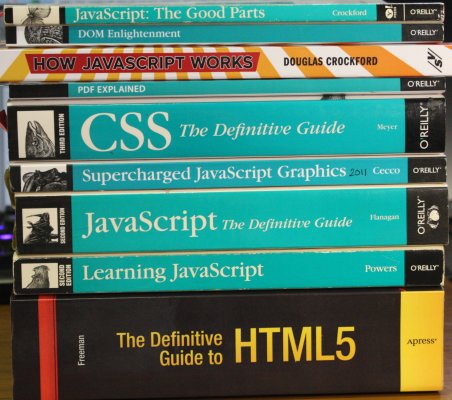

How did a nasty leg infection prompt me to buy some Javascript books? That makes as much sense as "collect underpants, profit!" right?

I'm an old assembler and C programmer. Object Oriented software fashions seemed to me overly complex and fraught with new kinds of traps, and didn't excite. I'm always pleased to see aligned opinions of some far more knowledgeable than I, such as this: Object-Oriented Programming is Bad video by Brian Will. And some related ones from him. (But then recently he made Object-Oriented Programming is Good* Heh.)

With Javascript my stylistic curmudgeonliness is a distinct handicap. Although I know enough Javascript for simple things, for eg A Javascript Player for Animated Image Sequences, I'm definitely not yet able to write it with the politically correct OO styling, or utilization of the language's deeper capabilities, DOM functionality, etc. Being in my 60's also doesn't help. Not as quick on the uptake as I used to be.

Yet in recent years I've been accumulating a list of software projects I want to do, all of which suit the 'web front end programming' model well. That list of JS-based software projects is now up to 17.

Yet in recent years I've been accumulating a list of software projects I want to do, all of which suit the 'web front end programming' model well. That list of JS-based software projects is now up to 17.

All basically involve custom graphical user interfaces, running in a web browser for (relative) platform independence, and interfaced to various things — virtual data and/or physical devices. Some are just interesting ideas, others central to core projects. For instance one is a critical requirement for a later stage in the vacuum chamber project. Which makes it a must do.

I'd been lackadaisically gathering texts on Javascript and other web front end related magics, reading a little now and then. Online sources and physical: →

Here's an incomplete list of general topics involved. Far from all:

AJAX, DOM, ECMAScript, Electron-js, Greasemonkey, Grunt, HTML5_canvas, jQuery, JS_C_interface, JSLint, JSON, Mathjax, Minify/Unminify, Node-js, NPM, React, Semantic_Templates, Sizzle, Thrift, TypeScript, WebKit.

Then as the leg infection started, I'd initially thought it might be a recurrence of a rather bizarre problem I've had since 2015. It quickly became clear it wasn't, but it did remind me that I need to write a graphics utility to demonstrate an odd visual effect resulting from the existing condition. It's subjective and there's no other way I can think of to convey it to the doctors involved. Remarkably, I've found that language-based descriptions just bounce off them, repeatedly.

Anyway, I want the visual demonstration to be web portable. And Javascript + html5 canvas seems by far the best option. But the techniques required are beyond my current html/css/js abilities. Hence more books on the topic, and more time reading.

Still just learning, so there's no point explaining that (or any other) software project. What works, will be posted. Maybe some that don't work too, once I'm sure they're dead. The JS & front-end tools learning curve has been the primary obstruction to my other standing software projects, so they'll benefit. Conceivably this site might be improved too. Maybe.

And btw, two web pages that convinced me the JS/browser technology is now capable of doing various things I want, are the weather sites Ventusky and Nullschool. If you haven't seen these yet, go have a play with them.

|

It was Golden Staph, not Tetanus. Fortunately an anti-biotic susceptible type. Though BH didn't know that while I was there.

He recommends just leaving the wound uncovered, so long as it's not weeping.

|

Btw, pics of the shin wound tend to be poor. Because I cannot look through the viewfinder to take them. Can't contort to have my head closely above shin. Have to just guess framing by judging the camera lens axis from the side, and hope the autofocus gets it right.

|

|

|

|

|

Healing continued. Pics on April 26th, 30th, and May 2nd, two weeks later on May 13th, and a couple more months on July 14th.

Great, time-weavils with a taste for flesh. Well I'm used to that, due to other problems. I thought this example was over, but I was wrong.

During the above, someone on a classic computers mail list asked for a Televideo 925 character rom dump. Hmm, I have a... oh no wait, mine is a Televideo 924. It turns out the 924 model is almost unknown, so it was worth opening up to dump the ROMs from it too. Zipfile here.

|

|

|

|

|

|

|

|

|

|

I wasn't feeling well enough to pursue reading U10 char-gen (making an adapter) and why the 8049 wouldn't read.

All this time the HP spectrum analyzer had been sitting open on my 'side table' (the table also unfinished.) By now it was clear the issues with printing the two PDF service manuals were not going to resolve easily, and it would be a long while before I'd get back to actually attempting to fix that instrument. So, with sadness I decided it would be best to close it up. For its own protection, and to free the workspace.

|

|

|

|

|

I like smallish old LCD monitors, in the 40 to 50cm size range. They are light and convenient to move around, fit in limited desk and rack space, and best of all are free. Because people throw out perfectly working ones, as 'obsolete.'

This time I found two kerbside tosses, that unfortunately had been out in heavy rain. While in a pile of junk that included disintegrating dusty chipboard, and plasterboard. The rain had splattered loose wood fibers and plaster gunk all over and through the monitors, and they looked pretty bad.

Which made it more interesting. Would they work if cleaned up? I though probably not, so didn't bother with pics of cleaning the first one.

|

|

|

|

Huh! Well that was unexpected. I just cleaned the cases and screen (compressed air, brushing and spray cleaner), and cleaned the PCBs (air and brushing, not even IPA that I recall), and they both worked perfectly.

In the late afternoon I'd been driving home, and would pass by a friend's place. So I stopped to drop in and say hi. He wasn't home, but getting back into my car I noticed a pile of kerb-tossed junk on the other side of the street. It didn't look interesting so I drove off. Half a block up the hill there's a corner with a general store. I was mildly peckish and there was parking space right by the roadside so I stopped to buy an ice cream. Then decided I didn't want to sit in the car eating it; might as well go for a short stroll. For want of anywhere better, why not back down to that junk pile? The walk there and back to the car would be about one ice-cream's unit of time.

The junk pile (as expected) held nothing of interest so I started walking back up the sidewalk. Casually, enjoying the nice afternoon and ice cream. Half way back, there's a yellow motor bike parked, rear to curb, facing a little downhill, so now as I approach I see it more front on. I hadn't paid any attention to it while driving then walking by moments ago.

|

|

|

|

|

|

But now I see it has a small hand-drawn paper sign on the front. As I get quite close I can read it. "For Free"

Such a small, low contrast sign, it can only be read from quite close. And with the angle the bike is parked, the sign can't be seen at all from cars driving by on that side of the road. (We drive on the left.) From the other side of the road, it's far enough the sign probably wouldn't be noticed. You'd have to be walking uphill on the sidewalk to have much chance of spotting and reading it.

I went and knocked on the door of the house. The story: The bike had come as a freebe with purchase of a much larger bike about a year ago. It 'has problems' but the motor did run at some point. They'd never used it, and it sat around in the back yard ever since. Now they wanted it gone. There is a key, but the son who might know its location was out at work. I was welcome to take the bike.

The photos are taken after dark, on my return with a trailer. By now my friend was home. He had an old washing machine he needed to get rid of, so I offered to pick that up while I was there, and take it to the recyclers. I have a ramp for the trailer and with assistance of two friends we rolled the bike up. Eventually the owners found the key for the bike, after a lot of confusion.

The Bug Bike has only 325 Km on the clock. It would be perfect as a low running cost local runaround backup, for times when my old car is off the road (not an unusual event.) Free, is a good starting point. Whether I do actually use it will depend on what it takes to get it running and registered.

Of course nothing's perfect. The downside is that previous owners for some reason had messed with it. A lot. Some of the electrical wiring is wrecked or actually missing. They took several of the indicator lamp lenses off, and somehow lost them. A couple of body panels are loose (came with it) and others have missing screws. The tires were nearly flat. In short, Chaos has touched it heavily.

Another long-term unfinished project, great. But I like the look of this bike.

|

|

|

|

|

1. Didn't even take it off the trailer, just stripped it in place. 2. There's the junk about to go. 3. An improvised puller to get the tub apart. 4. Nearly half the weight of the washing machine is in that green UFO-shaped cast iron thing, with the axial shafts. What does it do? 5. Undoing its bolts and cracking the seal, the first discovery was that it's full of gearbox oil. For some reason despite it being so massive and having an obvious oil seal gasket around the rim, it hadn't occured to me that it might, so I first cracked the seal on the ground without a tray. Oops! A quick diversion to scoop up the oil-soaked soil and bin it. Then proceed, this time with a tray.

|

|

|

|

|

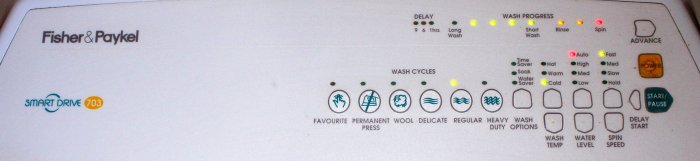

1, 2, 3. Who'd have expected to find a truck gearbox inside a washing machine? Wowee, this thing was never going to fail. And didn't. The washing machine was replaced due to failures in the electrics, specifically a circuit breaker in the control panel that kept popping. My friend had been given a newer machine, so didn't wish to repair this one.

Functionally it's quite impressive. Depending on which direction the drive shaft is turning, the motion transmitted on the output shaft is either the tub agitating back and forth, or the continuous spin. A mechanism complicated enough that if I tried to explain it, this would be very long. So I won't. But I was glad I'd opened it up.

4, 5. The curious features didn't end with the gearbox. The stainless inner tub was much heavier than I'd have expected. The upper rim is hollow, with a plastic sealing plug. Inside, a fine gray sandy powder, with uniform grain size. Very heavy; it feels several times the density of ordinary sand. I wonder what it is? Maybe some kind of sand blasting grit, repurposed as a spin vibration dampener? Or just ground-up blast furnace slag?

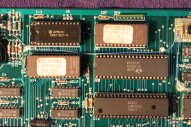

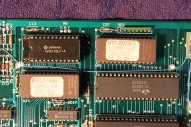

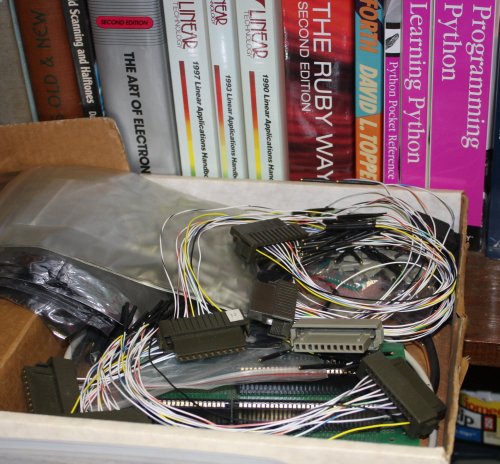

While starting the restoration of my old Apple II, I'd set up my HP 1630G logic analyzer in that work area too. There's a box with all the probe acessories — pod lead sets, clip hooks, etc. I'd left this open, and of course the kittens thought it was a great snooze spot with ideal box-nature.

While starting the restoration of my old Apple II, I'd set up my HP 1630G logic analyzer in that work area too. There's a box with all the probe acessories — pod lead sets, clip hooks, etc. I'd left this open, and of course the kittens thought it was a great snooze spot with ideal box-nature.

(Pic is a reconstruction of the crime scene.) →

The kittens are 4.5 months old, definitely around peak cuteness. So I let them sleep wherever they like.

By now you've guessed what happened, so the mystery is gone, right? Well then, care to guess who did it?

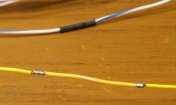

Those lead sets for the logic analyzer pods are really special. Very fine, flexible multistranded wire, in brightly colour-coded teflon insulation. The sockets for the hook clips are molded onto the wire ends, and I never could work out how to extract the pins from the pod connectors. I have exactly the same number of lead sets as the analyzer's pods; seven.

On the evening in question, around 6pm, I was sitting at my desk, web browsing. Kitten who shall be known as 'S' had been sleeping in the probes box, but had just woken up. I heard two clicking sounds from his direction in quick succession, and thought "Whut? That sounded like... small wires getting snipped?" I turned, just as he bit through another one, with the same sound. Very quickly I yelled "noooo!" and jumped up, grabbing him out of the box.

It's impressive really. Three perfect clean cuts, two in one wire and one in another. As if with precision side cutters.

|

|

|

|

|

I've had that 1630G since my 30s (ie going on 30 years now) and used it a great deal. Once when fixing a fault I'd bought some spare 10K series ECL ICs for it. Other than those I have no spares. Hunting through my stock of wires confirmed what I knew anyway — I have nothing the same as these fine flexible wires. So even if I could get the cut wires out of the pod connectors (how?) I would not be able to replace the wires.

But to splice them, they really need to remain as close as possible to the original length, since for timing delay all the wires should match. Not to mention visually. The single-cut wire could be spliced losing only a couple of mm. The one with two cuts needed two splices, resulting in an annoying loss of length if I reused the loose section. Best to use another longer segment to equalize length. I'd found some wire that wasn't too far off in appearance, though thicker and less flexible.

The minimal splice technique is, strip a very short length, lap two ends together, wrap tightly with a single fine wire strand for strength and neatness, solder. Tin-lead solder is brittle under flexing and stress, so the wrapping is essential. Finish with fine heatshrink tubing (which you remembered to slide onto the wires before making the joins.)

The last photo is an aside. While looking for potential replacement wire I'd cut open a HDMI cable junked due to a broken connector. The internal wires are quite nice, very fine, most of them in twisted pairs. Potentially a useful hacking resource.

Well, the splices don't look too bad. Though soon afterwards I thought of a much better way I should have done it. Sigh. But this reminded me of my lack of spares for my dear old soldier of a logic analyzer. I stepped into US ebay to see what might be available in the way of spare lead sets.

Typical. Lead sets by themselves, nothing. Complete working HP 1630D logic analyzer with four lead sets, for $20, yes.

Well that's even more spares I guess. For a high shipping cost. I bought it, and off it went to my US reshipper.

Also typical of the ebay experience, while searching I'd come across this listing:

HP 10269B General Purpose Probe Interface 10272A, 10271A, 10273A — Pins damaged on cable.

|

|

|

|

|

Priced at US $149.99, that was too expensive for something I didn't really need. A complete set of 7 pods for a 1630G, a GP interface module (I already have one), plus a specific CPU adapter. Those pods contain a great big ceramic substrate with thick film components and active interface parts. I've always worried that dropping a pod onto a hard surface could easily fracture the substrate. Hence handled them very carefully, but accidents can happen. Having more spares would be nice.

I added this item to my ebay watch list. It's relatively small and light, shipping would be reasonable.

Two months went by; it was still listed. How many people would still be actually using an old 1630, enough to want spares? And of those few, most would be turned off it by those bent pins on the header, because they look like a disaster. Maybe the seller would be getting frustrated by now? I offered $50. One third his asking price, normally not likely to be accepted. I included an apology for the low offer, mentioning shortage of funds (very true) and that I only wanted it for spares. The seller graciously accepted!

It arrived on 20190716, everything good. I'd known those bent pins don't matter, because they are sacrificial. There is another identical header underneath. (Pic 5) Just carefully lever off the broken one, and replace. I have several with my other sets. Also the module plugged into the bottom of the adapter is for a Z8001 CPU, which is a very rare module. And I have the matching reverse assembler software for the 1630G. Really nice to add this to my collection.

So which kitten bit the leads? If you guessed the black one, you're a raaaycist. And wrong. It was Chubbers, the fat clown.

But she's also increasingly prone to falls. Standing anywhere near the long concrete staircase top was becoming a worry for her. So she asked if I could make a new place to feed the possum, away from the stairs.

Of course!

|

|

|

|

|

1, 2. There's already a bird/possum 'nest box' on the tree by her patio front door, that I made long ago. Nothing is actually attached/screwed to the tree, it just stands there. Held up by a beam to the ground, a torsion-brace off to the house roof (also serves as a possum bridge), and one thin stainless wire looped around the tree trunk in a length of plastic hose pipe.

The existing feeding spot is the dark patch on top of the painted brick wall at right. The new one will be behind that shrub at the tree base.

3, 4. Nothing special about it, apart from a bunch of odd angles and being totally an on-the-spot improvization, with some scrap wood, handsaw, and long woodscrews. Still no attachment to the tree, just the existing vertical beam and the ground. I wanted to at least paint it, but she insisted that wouldn't be necessary. "Only needs to last a few years" she jokes. Which I suppose is true.

5. The shorter distance from the outside door is greatly appreciated. The possum likes her pedestal too, as she can climb up and down the vertical softwood beam easily. I didn't get a photo of the possum there yet. But she's comfortable enough with humans to eat from your hand, sometimes.

A guy on the electronics forum PM'd me, asking if I really had a copy of the Hewlett Packard Application Note from June 1980:

A guy on the electronics forum PM'd me, asking if I really had a copy of the Hewlett Packard Application Note from June 1980:He'd found it doesn't seem to exist online. I'd somewhere posted a list of the old HP App Notes that I have, and yes, I do have that one. I didn't want to sell it, but would scan it.

I posted a 'draft copy' on the 12th, here:

http://everist.org/archives/scans/HP_AN_64-3.zip 5.8 MB

It's OK but I'm not entirely happy with it for several reasons. See notes at the end in the file.

← That's a big paperweight!

At the ACMS Central Coast storage site, the rest of the day was spent tidying the great amount of stuff there. During which I had a second treasure find, of a set of software manuals for the Hewlett Packard 1000-series minicomputers. Which I was allowed to remove for cataloging, see 20190620 Manual Labour. These are priceless for me, due to my own HP 1000 minicomputer restoration project. (Stalled for a long time due to lack of some critical documentation.)

I mentioned that for a few days I'd been feeling off. I knew what it was, and had hoped it would be a minor repeat of a problem I've had since 2015. But no... this time it blew up into the worst experience yet.

I mentioned that for a few days I'd been feeling off. I knew what it was, and had hoped it would be a minor repeat of a problem I've had since 2015. But no... this time it blew up into the worst experience yet.

I have a recurring blood infection with a bacteria called Aeromonas Hydrophila, contracted via a leech bite during a coast bushwalk in March 2015. See map →

This is an unusual infection. Typically people only contract A. Hydrophia via contaminated water entering a deep wound, since a working immune system can defeat it in small numbers. But once it does take hold it's one of the 'flesh eating bacteria', and can be lethal. It is a relatively common bacteria that often lives in polluted water (like where I got the leech bite) and can be transmitted by leeches.

In me it thrives due to my genetic haemochromatosis (high blood iron levels, impaired immune function), the combination of which makes me much more susceptible than most people. It persists despite many antibiotics courses due to a reservoir population site (vitreous humor of the eyes) unreachable by the immune system and antibiotics. The vitreous has virtually no diffusion from the bloodstream (either of drugs or oxygen), thus can easily be turned anaerobic by such a bacteria. A. Hydrophila is motile with a flagella, swims quite well, and can switch back and forth between aerobic and anaerobic metabolism, thus can survive in the vitreous.

There is an exit path by which the bacteria can travel from the vitreous humor and reach the bloodstream. Normally my immune system can suppress this continual low-level re-introduction of the bacteria. But now and then it misses, and either a local colony or a systemic blood infection starts up.

Aeromonas Hydrophila produces a cell-wall pore-forming toxin called Aerolysin. Affected cells die by lysis, ie swelling with water osmotic inflow and bursting. That toxin produces most of the gross symptoms such as tissue oedema at various local infection sites, and is excreted via kidneys to the bladder where it causes serious bladder lining and urinary tract inflamation, bleeding, cell shedding, etc, with no AH ever found in urine. Consequent to the damage there can be secondary UTIs and/or asymptomatic bacteria present in the UT, complicating matters. A. Hydrophila infections can progress to necrotizing fascitis and death if not treated promptly. So far, all my flareups since 2015 have been stopped with antibiotics. It still takes weeks to recover each time.

I have a highly detailed writeup of this saga, 2015 to present, but it's not public yet due to potential future medical malpractice legal action. It's extraordinary and distressing to experience the incompetence and block-headedness displayed by very many medical professionals, when confronted with a unique, unheard-of syndrome, that only exists due to a quite unusual combination of unfortunate circumstances. 'Not in the text books, therefore can't exist.' Bah.

Besides, if you thought that Golden Staph infection sequence was icky, you definitely don't want to see my Aeromonas saga. So I won't go into great detail here. Just note the amounts of time this one ate away. Btw it's quite painful and unpleasant, and has some seriously detrimental long term effects. Apart from potentially killing me if it ever starts up a local infection somewhere critical, or for some reason I'm unable to whack it with antibiotics. Otoh, if you are actually interested and are qualifed to perhaps provide some useful input, just ask me for the documentation.

This instance could have been merely another random flareup, or perhaps my immune system 'took a nap' due to that Golden Staph infection, plus a few late nights, plus feeling low (see the Spectrum Analyzer disappointing events), plus some exertions and other stresses. Impossible to know.

As an aside, here's some pics in sequence from that walk on March 7th 2015. It's the Coalcliff to Austinmir escarpment track, and it was a pleasant day out. Too bad about the life-disrupting long-term infection.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Row 1, #2. Where I left my car, near Coalcliff. #3 "Do not leave track" ho ho ho. But that is partly why I'm here today — searching for some old mining relics. Hence that extra wiggly bit at the top of the walk map.

Row 2, #1 & 2. Different views of the same place, where I picked up the leech. I'd been settling down in a bushy clearing just off track to have a morning snack. As I was getting food out, I noticed there were numerous leeches on the ground around me, all inching my way. (They sense body heat.) I relocated, checked my bare legs, saw none on me. As an experienced bushwalker leeches are routine. I've had many leech bites before, merely a minor nuisance. I thought nothing more of these ones, and continued the walk.

Row 3, #1 & 2, The view from a clifftop where I had lunch a couple of hours later. And discovered the leech on my foot, down inside the shoe. It had worked it's way through the sock and had been feeding all that time so was a very fat blood balloon. I pulled it off, stomped it (hence the splash of blood from it bursting), and only then thought to take a photo (pic #3.) Also forgot to take a closeup.

Row 3, #1 & 2, The view from a clifftop where I had lunch a couple of hours later. And discovered the leech on my foot, down inside the shoe. It had worked it's way through the sock and had been feeding all that time so was a very fat blood balloon. I pulled it off, stomped it (hence the splash of blood from it bursting), and only then thought to take a photo (pic #3.) Also forgot to take a closeup.

At the time I didn't think it was significant, so this is the best pic I have of the little critter that thoroughly eff'd me up for years. A very effective time-weavil.

The rest of the walk was enjoyable and routine, apart from an uncomfortably close encounter with a large brownsnake, and the minor issue of continual slow bleeding from the bite (leeches inject anticoagulant) with resulting squelchy sock. Then after getting home, unpacking and sitting down, I suddenly developed a fever of 38.5° C. Skipping a lot of detail, 9 days later I was in Bankstown Hospital, experiencing both the full nastiness of a systemic A. Hydrophila infection (which I didn't know at the time), and astonishing medical refusal to listen to details and comprehend an unusual case. They insisted my leech bite story was a fabrication, and wouldn't even look at a USB drive I offered them, with photos of the walk, leech, and bloody foot. Including these, taken that evening after I'd got home.

|

|

|

|

|

They flatly stated to my face that my 'leech story' was a red herring, and there was nothing that could be caught from a leech. At the time I didn't know they were full of it, or what the actual bug might be. Despite their 'no such vector' insistence, the Bankstown Hospital discharge letter I was given later did mention Aeromonas Hydrophila as a potential suspect. They hadn't been able to positively identify any bug, but now I had a name to research.

|

If you think that all sounds hard to believe, well, for brevity I'm leaving out many details including the most bizarre and consequential. Because it's really complicated and odd. It's what that Javascript graphics program is to visually demonstrate, since in my experience of attempting to conveying this, words just don't work. All in the full doco.

Anyway, back to the present in 2019. I'd been feeling a bit off for a few days, plus some odd sharp muscle aches. It felt like another low level Aeromonas activity (it's a very distinct feeling, though I won't try to descibe it here.) Then the evening of Monday 13th, around 1:30am, preparing for bed I got a sudden very bad bout of diarrhea. Oh oh. Sure enough it was a major flare-up beginning. Feverish, plus rapid onset of all the symptoms of having aerolysin in the blood and urine. The worst of which is that the bladder lining swells up dramatically, with lots of cells dying. This one developed very rapidly and severely. Tuesday was a writeoff, very sick indeed and getting worse despite having started antibiotics right away.

Interesting, but I'd rather not have had to. The urinary system swelling had developed to complete urethral blockage. The ambulance at 7:30am was because I couldn't have driven myself, due to pain. Plus the fear of being left in the casualty waiting room for hours in this condition.

This time BH was fairly prompt. Catheter fitted, I.V. antibiotics, and I'm out of there around 2pm.

After getting back from hospital, with the fever knocked down by antibiotics, and the catheter restoring mobility somewhat, on the 16th I started working out how to improvise some bookshelves for the HP 1000 manuals. Came up with a workable method using some stored scrap timber, but was still pretty ill and dealing with the symptoms for the next ten days. Very poor sleep, could only do a few minor chores.

|

|

|

|

|

1 to 3. That Documation TM200 card reader has been sitting around in pieces in the workshop. Not being able to find a schematic for it is a bummer. I've still to finish machining the mold to make new rollers too, though that's more just a case of distractions, not any actual hurdle. Anyway, it's best to put all the major bits together and store in one place. Here just finding and installing new rubber feet on the cabinet. The old ones were completely missing, letting the thing rest on screw heads, scratching any surface it's placed on.

4. Relatively tidy. This won't last long.

5. For another project I've had under way for about two years, I need a 'narrow wheelbarrow', that also needs to be possible to dismantle and carry quite a long way in the bush. It likely won't survive the project either. So I'd bought a very cheap, light wheelbarrow kit from Bunnings. The tub is going to have to be cut in pieces, to make it narrower — both for portability and to fit the loaded barrow between obstacles. It will also need a reinforcing base sheet of metal. Here I'm just contemplating how to do that.

|

|

|

|

|

|

|

|

Well it did, enough to scrub it off with a stainless steel scourer. So did the fingertips of the 'chemical gloves', oh well. Anyway the repainted top cover looks OK, though the paint colour isn't a perfect match to the sides. The rusty transistors were a real pain. They are garden variety 2N3055, of which I have a bag new. But in this supply they have too much circuitry directly soldered to their leads and mounting screws for disassembly to appeal. So I just sanded off as much of the rust as possible in situ, then painted with a rust suppressing enamel. Mica insulating washers and all. Black paint would have been better visually, but I had a little bit of this blue paint left. Use it or throw it out...

An appointment at Bankstown Hospital 'Ambulatory Care', for a trial removal of the catheter after wearing it one week. Their standard interval. I expected this might be too soon, since from my experience of damage by Aerolysin it takes a lot longer than that for tissue swelling to diminish anywhere back to normal. Presumably a lot of cells have just a few holes punched in their walls, and survive despite remaining bloated from water inflow. But nobody except lucky me ever gets recurring Aeromonas Hydrophila infections so there's no institutional experience of this syndrome.

I was right, it was too soon. Still a complete blockage. This makes them assume it's a permanent problem so the catheter goes back in, this time with a next appointment in a month. In case I can't see a urologist before then.

Never mind. The pain and discomfort I'd been having was mostly from the actual injured tissues not the catheter itself, and was continuing to diminish. By now was not so bad. I was still on antibiotics and I knew things would continue to improve, getting back to normal in a few more weeks. Yes, it really is slow. Aerolysin is awful.

Btw I'm quite familiar with the BH Ambulatory Care section. I've been going there every three months for a couple of years, to have half a liter of blood extracted (and thrown away) each visit as treatment for my haemochromotosis. Reducing blood iron levels. It's slowly working, but is only a treatment, not a cure. The staff there are nice, and competent. As opposed to some others at BH.

|

|

|

|

|

|

|

Who doesn't love a big parcel from overseas? Also cheers one up when not feeling well.

It works perfectly and was remarkably clean inside and out, very little dust. But I gave it a good cleaning anyway, partly because I just like looking at how well HP made their stuff. Also here is the EPROMs dump for the HP 1630D.

The user manual for my 1630G covers the D model as well. I was quite surprised to find that while the G uses a HP 9121 dual floppy drive unit for storage, the D model cannot, and instead requires a magnetic tape cassette unit for storage! That really highlights just how old these things are.

|

20190525 Projector PS disassembly

I'd been given most of the guts of an impressive 70mm film projector, for pull-apart fun. Seems I forgot to take pics of the projector cabinet disassembly, but here's the power supply getting boiled down into usable parts. Last pic is part of the projector case being cut up into flat sheets for storage. 20190526-28 Bookshelves built. Finally. See Manual Labor. 20190528 Hair Chair

This is ridiculous. My work desk roller chair was starting to have wheel-jams. When I looked at why, my goodness. I suppose that's several years's worth of beard hair shedding. Apparently the roller wheels are very good at picking up hairs from the concrete floor and wrapping them around the wheel axles. 20190529-0602 Cleaning Manuals. See Manual Labor. 20190531 At last the catheter removed OK. Life almost back to normal except still on antibiotics, still some bladder damage and discomfort persisting. Gradually improving. |

20190529 November Wolf

A friend from the USA flew over for a conference in Sydney, and dropped in briefly for a chat. |

20190601 An Urbex Evening. Long and quite exhausting. Teaser pic.

|

|

|

20190604 Fridge upgrade. Some time ago the fridge in the house died — thermostat. I'd bought a new thermostat and installed it. However it turned out to be way off expected adjustment, and froze everything in the main fridge compartment. My ex-wife decided it was time to buy a new fridge. So I got the old one. It sat in a storage shed for a while.

Meanwhile the fridge I use in my workshop is small and old. I finally got around to swapping up.

1. The small entrance space needed an improvised ramp to get the big fridge up and turned into the doorway.

The fridge required a lot of cleaning, so was a few more days before it was ready to try out.

2. The thermostat (with a cover removed.) There are two adjustments, that of course have to be set-point and hysteresis. But which is which? I'm pretty sure but not certain. There's zero documentation (even from the supplier) and it takes ages for the fridge internal temperature to settle down after any alteration of these.

3. Beginning several more days of running it empty, with accurate temperature readouts.

|

|

|

20190604 Oops! That film-advance servomotor from the 70mm projector was interesting. High torque, very low mass on the shaft, so high accelleration. Forced air cooled. The smaller cylinder on the end is a servo sensor, producing a DC voltage proportional to rotational speed.

I decided to take it apart to see the insides. Carefully! First thing is to remove the wires from the carbon brush mounts, and also remove the carbon brushes, so they wouldn't foul on anything inside as I slid it apart. There are two small screws on each brush cover for the servo sensor. With the first one, I removed one screw, loosened the other then rotated the cover sideways carefully. Expecting to find one spring end in the center.

Surprise! There are two springs per cover, close to the edges and very small diameter. I'd barely recognised that I was seeing a spring end already, when it just... vanished. There was a faint 'tink!' sound from across the room. In the area holding lots of machinery, piles of jumbled metal bits, and plenty of swarf. Bah.

Hours of hunting, sweeping of floor and sifting the dust, and that little spring is still gone. Well that made me feel stupid. Maybe it will turn up the next time I tidy the drill press and mill bench, or the junkpile underneath. Or never.

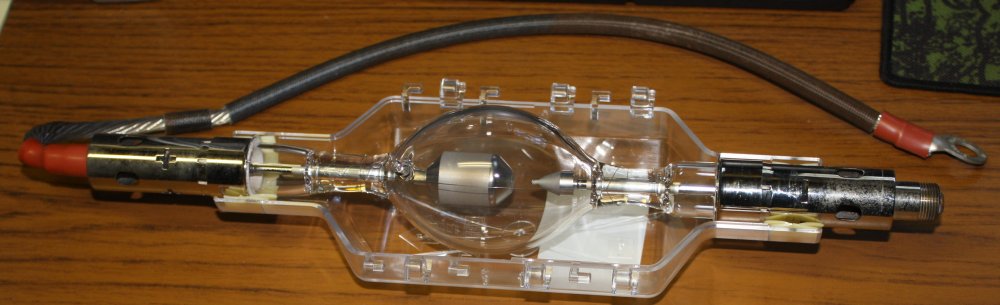

Shown here with one half of the protective transport case removed. It's to protect bystanders more than the tube. These are high pressure Xenon lamps, and if the glass envelope cracks the flying shards can penetrate flesh to major arteries. You're supposed to wear something like full body flak armor when handling them out of the transport case.

Anyway... I also have some high voltage lamp 'starter' units, plus one large parabolic reflector.

|

Starting with the transformer/rectifier unit. Which btw, is primarily intended for use with my vacuum chamber system, not these lamps. Previously mentioned here. Yes it's been waiting since 2012. Sigh.

The paper puppets were to help decide on meter positioning.

|

|

|

|

|

|

1. Someone in the past had mounted a plastic control box on the junction box lid. It has to go. So do its five holes in the metal lid.

2. Preparing to remove the holes.

3. By filling the holes with weld metal (firebrick backing.) This of course warps the flat steel a lot.

4. Grinding the welds flat (both sides.) The sheet is still warped.

5. Fixing the warp. It's due to the weld metal shrinking as it cools (after solidifying), which draws in surrounding sheet, turning it 'saddle shaped.' The solution is to hammer the welded parts (firmly) to make them slightly expand horizontally. Thus relieving the tension stress in the sheet. Result: the sheet goes flat. (As expected, but it's still a relief to me to see the theory actually work.)

6. Painted. The old paint is 'crinkle' texture, and the new is gloss. So I just sprayed the entire panel, and don't care about the texture difference.

|

|

|

|

|

|

1. I have the product brochure for these IREM transformers, and operating gauges were optional. This one came without. Some salvaged gauges (and matched current shunt) are 'close enough' (bit low on the current range.) Here using the salvaged unit's front panel as a marking and drill template for the meter holes.

2. Preparing to make the large round holes, with a hydraulic punch. Unfortunately the largest die in my set is about 1mm smaller than needed.

3. Punching in progress. It's very quick and easy. I love this tool.

4. Done. Now for the hand filing to get rid of the remaining millimeter of hole undersize.

5. In place. But not wired up yet, and there's still some control circuitry to implement.

6. Power supply lead done. (Still needs the controls.)

|

|

|

|

|

1. The dirt road start point is the old Zig-Zag rail station on Chifley Rd. I was a bit early so went for a walk. This is looking down on the long abandoned rail line where it enters a tunnel.

2. We'd be camping Sat. night at the Barcoo Swamp campground. It's just a clearing, not actually a swamp. No amenities. Only one other of our group had arrived before me (and reserved the spot we wanted), and I was curious to see if there was a more secluded campspot at "B" on the map, so went for a short drive to scout.

3. My car is 4WD, though nothing special in ground clearance. This pic is about point "A" on the map, where I decided to walk the rest of the way down this hill. No cell phone signal here, and bottoming the car would mean an annoying rigmarole involving a long hike back and asking for a tow. Pointless, and I like walking.

4. As I'd expected, the road deteriorated further. And that "B" potential camp area? Nope, it's just where the first road had washed out so they cut a detour. These 'roads' are pointless except for 4WD-heads in monster trucks, who like making the bush erosion problems worse.

5. Back to the camping area, with others now arriving. After collecting firewood, by then around dusk, I set up my tent well away from everyone else. I like to be able to get to sleep, regardless of who stays up till dawn or whatever. Also, tussock grass, it's nice and soft. In contrast to the very short grass and hard compressed ground in the central area.

As for firewood, sigh. People started picking up sticks off the ground, before I went and found some nice solid, thick, still standing deadwood. Not rotten or damp, as opposed to everything that's been lying on the ground for a while. Then had to explain that no, you don't need to cut it up into short lengths with a chainsaw, no matter how thick it is. Just lay a few of these long, straight logs parallel, all with one end where you're starting the fire. Then feed them in as they burn. Minimal effort, works much better than the silly 'conical teepee' cartoon fire most people seem to aim for.

These friends are all members of an Urbex group. Barely any bush skill among the lot of them, though several are 4WD enthusiasts.

|

|

|

|

1 - 3. The rest of the group's camp. Actually we were lucky with the weather (and that rain tarp is justified) since it had been spitting a bit in the afternoon, and this had discouraged all the hoard of weekend pretend-4WD types. There were convoys of them on the road, leaving in their huge shiny SUVs as we drove in. But it never rained more than a few drops through the early evening, with clear skies later that night. Nice.

4. Next morning, my campsite packed away and ready to get going by 10:30am.

I thought this was already very late. It's a long, painfully bad road drive to get to this place, and lots to do there. Sleeping in is a terrible waste of opportunity.

|

|

|

|

1 - 3. But we'd all stayed up till about 3 or 4am, so a late start was to be expected. And most people like a hot breakfast, so... lots of set up and cooking time. (I have a quick pre-mixed muesli, powdered milk, some bread and butter, jam etc, and that's my camping breakfast done.) And of course there'd been a fair amount of drinking in the evening (and some this morning too), so no one was feeling spry. (Except me, since I never drink alcohol.)

On Saturday I'd mentioned wanting to spend Sunday looking for a really cool mini-canyon I'd found decades ago, but never found again. Others had expressed interest last night and even a bit this morning. So I was waiting hopefully for some progress towards readyness, as the clock ticked. It's always like this with these guys. They are 'urban explorers'; very intrepid in city environs but not much interested in bush adventures.

4. A smaller restart of our fire, Sunday morning. During the night we'd run it quite large and hot. Anyway, it illustrates the 'all parallel' arrangement I mentioned.

|

|

I think it will always happen, without exception. It's frustrating.

1. To rub it in, there was a group of young Chinese camped adjacent to our group, who we'd had some conversations with in the evening. They planned to do Rocky Creek Canyon on Sunday (which I've done before, and liked a lot.) I had got up briefly around 6am Sunday morning to go pee, and they were up, ready and heading off to the canyon already. I was wishing I could go with them. But no wetsuit with me, it's middle of winter, the water in the deep canyon will be close to freezing, and there are long, unavoidable swims. Even if they'd have let me.

About 11:30am, the last of our group who I'd been hoping might come with me, mentioned he had to be back in Sydney around 3pm. Oh good grief. He could have mentioned that earlier. I'd been waiting around for hours. Enough. I left to go do what I wanted by myself. Except, it was already too late in the day to do both of the two things I wanted. One was to visit a nice big well-known dry canyon, just for a pleasant walk. The second was to bush bash around in that general area, searching for the smaller 'lost' one. I knew by now the second one wasn't going to fit in the time left.

2. Atop a stone pagoda, looking in the direction of the easy canyon. In Google maps, this one. It's only about 5Km from our campsite. Less than 10 minutes drive.

|

|

|

|

|

|

|

It's a very pleasant walk in. Well worn trail, easy, no scrambling, and dramatic scenes almost all the time. There were a couple of other cars at the parking point, but I didn't encounter anyone else till I'd stopped for a while in the 'tunnel' part of the canyon, to set up some time exposures. There I met two other groups passing. One a couple, the other about 5. All young and enjoying themselves.

By now I was determined I must do something about my lack of like-minded bushwalking friends. I used to have some (well two really), but they've both been dead for a long time now. Not counting my dad (also long dead) and his walking friends. Hmmm...

This all reminds me I'm getting quite old too, and want to do more of this while I still can.

|

|

|

|

|

1. The canyon exit, looking back in.

2. After returning to my car, I still had a while left. The main time limit was that I definitely didn't want to be driving back out on the incredibly pot-holed road, in the dark. So on the way back I turned off into a minor firetrail, to go visit a great lookout. (I'd been to it before.) The last section is a walk-down, so parked my car here at the end of the relative flat. The photo is of an enticing 'barely a road' leading off to the Nth from there. But I wanted to visit the lookout first.

3 - 4. The view from the lookout. It's a stone pagoda right on the rim of a high cliff.

5. Looking back to the pagoda when returning up the steep track.

I did go for about an hour's walk on that side 'road', that became just a walking track fairly quickly, and then no track at all while I was trying out a ridge I hoped might have a vantage point. It was a pleasant, active but peaceful way to end the day. However didn't lead to any more great views, so no more photos.

Here's an example. A power cord for a MS Surface.

Here's an example. A power cord for a MS Surface.

It's one of the 'magnetically retained' style. Not a bad idea in general, except Microsoft have managed to screw it up, in a different way to how Apple screwed it up.

With Apple it's a weirdly fragile soft plastic in the cable sheath that disintegrates rapidly in normal use. Microsoft used a more robust (stiffer) cable sheath, but the connector design precludes any kind of cable strain relief. So the cable sheath snaps anyway at the entry point to the rigid molded connector.

Now I've been asked to fix two of them, both failed in exactly the same utterly predictable manner. The outer sheath cracked, then the shield braid wires all snapped at the break. The inner two wires hadn't broken yet.

The catch is, that the fix cannot involve anything that increases the diameter of the cylindrical body of the connector, because that sits in a closely fitting depression in the laptop side. And if the connector doesn't fully settle in it doesn't magnetically latch, or make electrical contact.

|

|

|

|

|

|

|

|

|

1. Cut away some sheath, peel back the braid wires. Cut away some of the plastic connector body, to reveal the metal crimp arms.

2. Peel back the crimp arms, discard the short braid remnants.

3. Give the exposed inner conductors a wrapping of heat-resistant Capton sticky tape.

4. Wrap one layer (with a little overlap) of copper foil.

5. Press the outer braid remnants down over the foil. Squeeze the metal crimp arms over the copper foil. Strip some fine multi-stranded wire, separate out one strand.

6. Use the fine wire to bind the sheath braid to the foil. Doesn't need to be neat. It's just so no wires stick up when you're soldering it all.

7. Solder. Be quick about it, or the plastic insulation of the inner wires will melt, and the wires short out.

8. Tape tightly with a self-fusing rubber tape, or something similar. You have to stay under the diameter of the molded plug, near the end of the plug.

9. Add a heatshrink tubing outer sheath, mostly for appearance. The part of this laying on the plug cylinder on the side with the projecting tab, will have to be pared off. So the heatshrink tubing isn't providing any mechanical strength at the junction.

10. Oops, I forgot to take a final photo.

Is this the stupidest plug design ever?

|

|

|

|

|

|

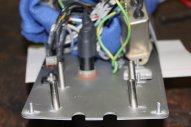

1-3. Checking the motor first. It's a 3-phase multi-pole servo-motor with electronic variable frequency drive and hall effect sensors. Disassembling it allowed to visually inspect the windings, and also measure the resistances of each phase winding. Everything seemed OK here, so I reassembled it. If it turns out to be a dead hall effect sensor, I can diagnose that from the controler end of the wires.

4. The electronics is all in these two green casings. Front one is the user interface (LEDs and buttons), while the rear one contains the CPU, power electronics, etc. Everything unclips and unplugs easily.