On Saturday 20180512 some friends of mine and I did a couple of tours of historical sites, as part of a Lithgow exhibition day. The first was of the Lithgow Small Arms Factory.

The tour information sheet.

|

|

|

|

|

I'd driven up to the mountains on Friday evening and camped overnight (pics 1 & 2) in a cave near Medlow Bath with some of the friends heading to the tour. We were booked for a midday tour and they weren't early risers, so I killed Saturday morning by myself around Lithgow, looking at a few old mining era ruins (pics 3 - 5) then met up with the others at the museum.

The museum at the factory is normally open to the public, and I highly recommend it. But that museum is just one building, on a huge site. Normally the rest of the site is off limits. On this day there were guided tours to view several other buildings and the old machinery still there. During WWII this place manufactured a great deal of the armaments for Australia's military efforts. That was all very interesting, however this article isn't about the museum or those tours.

One of the WWII relics on display, was a huge anti-aircraft* searchlight. It was operational, having been maintained for years and operated that day by an enthusiast who owns it.

(* Actually this one was intended for coastal defense, and so is awkward to point skywards, but it can be.)

|

|

|

|

Our group (foreground) and the searchlight.

The light source in the searchlight is a DC open-air arc, between carbon rod electrodes. It can run continuously, with electrode tip erosion compensated by feeding the rods in to maintain a more or less constant gap. The searchlight's owner, Nick (no connection to 'nutty Nick' from my recent lathe saga) became interested in these searchlights due to a career in theater lighting and cinema. He'd previously worked with carbon-arc spotlights and projector lamps, so was one of very few people with the knowledge of how to maintain and operate such a device.

I too had a smidge of relevant experience, since as a child at around age ten, I'd persuaded my parents and grandparents to buy me a real arc welding machine one Christmas. The whole family contributed to buying it, plus I mowed my grandparent's lawn for free for about the next year as part payment. I taught myself how to stick-weld steel (not very well), but also of course found many ways to play with it.

I still have that welder and mask (at right), though rarely use them these days due to having better welders (MIG and TIG) and an auto-darkening mask.

At that time my parents were renting a house in Oatley — 67 Waratah St. It had a large backyard, in a valley so the soil was deep and fairly soft. Down the far back, I'd dug a network of tunnels (mostly trenches, covered over with timber, corrugated iron and a few inches of dirt) plus a wooden tower-fort linked to the tunnels. I'll do a story about them someday.

Anyway, the tunnels had lighting in them using big old screw-terminal batteries and 6V torch bulbs.

Anyway, the tunnels had lighting in them using big old screw-terminal batteries and 6V torch bulbs.

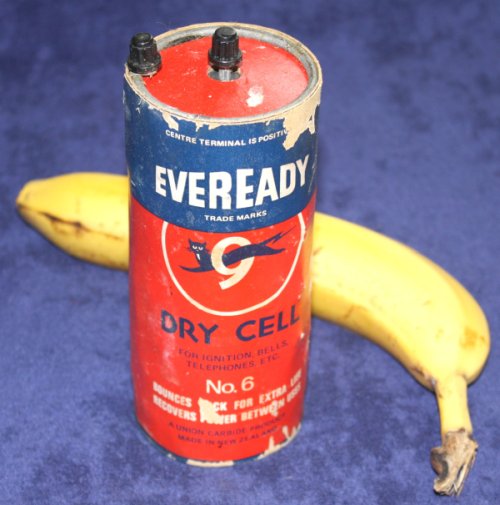

This is the type of battery. They are quite large, 15cm (6") high, and fairly heavy. The chemistry is carbon-zinc, 1.5V per cell, and they are not rechargeable. I don't think they are made any more, but in those days (1960s) you could buy them at local hardware stores.

When these batteries from my tunnels went flat, being an inquisitive kid I'd pull them apart. The term 'carbon-zinc' is accurate; the outer casing is made of zinc, and there's a big fat rod of solid carbon down the center. Playing with the arc welder, I found that if I clamped a pair of these rods to the welder output cables then struck an arc between the ends of the rods, the result was very impressive. Effectively a plasma jet, maybe a couple of inches long and quite stable. The rods did burn away, but fairly slowly so I had plenty of time to play with this arc.

Before anyone throws up their hands in horror and starts wailing about UV damage to eyes, electrocution, fires, battery chemicals, etc, don't bother. I wasn't a stupid kid. I was by this time an electronics hobbyist, knew all the relevant risks and how to avoid them. I had an arc welding face mask with dark filter, big leather gloves, and so on. I never had the slightest accident with this stuff. However I was still a kid, and when a kid has a plasma torch, everything looks like it needs melting. I'd melt steel things, and many of the rocks in the back yard acquired glassy pools of melted stone. All harmless fun, apart from my parents complaining about the electricity bill. But that turned out to be useful too (another story.)

Anyway, seeing this WWII searchlight running with a big carbon arc, brought back memories. Plus I happen to have a power supply for a cinema projector high pressure 5KW Xenon lamp, that is identical to but smaller than the transformer unit Nick was using to run the searchlight that day. Those are very similar in characteristics to an arc welder unit. Saturating core transformers, that allow adjustment of the output current by varying the magnetic coupling between primary and secondary windings.

So the searchlight restorer and I got to chatting. At one point I mentioned that I have a few of the genuine carbon rods, possibly exactly the same as the ones the searchlight is using. No, not the ones out of old batteries, but actual WWII searchlight carbon rods. I'd found them many years ago on the floor in an old WWII bunker.

Nick was very interested in these. Naturally they are not made any more, and he's short of consumables for his searchlight. I offered to give them to him, if they were suitable. It was time to go, the next tour group was coming through and he had to tend to the searchlight, so I quickly gave him my phone number. Typically people don't follow up on things like this, so I didn't really expect to hear from him again.

After the Small Arms tour, next on the itinery for most of the goup was a boutique brewery out on the fringes of Lithgow. I don't drink alcohol, but went with them to see the place. Then left to do some scouting of my own, preparing for an eclipse of the moon. That would be happening in a couple of months, on 28th Jul 2018 from 4am to 6:30am, setting at the Western horizon while still in totality.

For a telescope vantage point I wanted a cliff top looking West, with little light pollution. I'd been thinking of Hassans Walls near Lithgow, and had found on google maps a spot that seemed hopeful. So went to check it out.

|

|

|

|

|

Yep, it's perfect (pic 1.) A short track off the road (to the rear in that photo), but apparently little known. Down below is the Great Western Highway, heading North towards Lithgow around the other side of that ridge. There's an official lookout a bit further South along the Hassans Walls road, but that has been 'handicapped access enhanced', ie completely ruined by addition of massive steel walkways and railings. So no one can accidentally fall off the cliffs. Also happening to make it impossible to get a big telescope to any useful vantage point, not to mention making the spot look like crap. This was sad to see; last time I was here some years ago it was 'unimproved' and vastly more fun and scenic for that.

With more time to kill, I went for a walk up to the top of the nearby higher point to the North. There's a clearing, but surrounded by trees so not suitable for my eclipse watching needs. Walking back down the fire trail I found a 'lost track' heading off down a small canyon to the side of the road. Amusing; the track is invisible from the road, but I could feel a call from that place. Walked 20 meters into the open scrub and found a set of stairs carved into the sloping rock, mostly covered in leaves. No one has used these stairs for a long time. Pic 2 is looking back up them towards the road, out of sight there. The remnants of this path lead down to an old track skirting along the base of the cliffline. Pics 3 & 4. This too hasn't been trodden by human feet for a long time. In more wooded parts the track is discernable only by the ground profile under thick undisturbed leaf cover.

Now that track is on my todo list, but I didn't have time to follow it far this day. By now the rest of the group were finishing their hipster beer tasting session, and we met up in a Lithgow field for some late lunch and viewing of a legendary Lithgow mining relic (not going to say what it is, it's a secret.)

A bit more stuffing around in Lithgow including a very dodgy old abandoned rail bridge (pic 5) then we headed off to an evening guided tour at Wallerawang power station.

This is a large old coal-fired turbine generator plant, that so far as I knew had been mothballed. When last operating in 2014 it had two 500MW generators. It was one of two major power generators to the West of Sydney, the other being Mount Piper, which is still running.

There are several advantages of massive spinning generators like at Wallerawang.

- They provide very stable and reliable power, that allows a nation-wide power grid to be predictably maintained despite load fluctuations and other transient problems. With only a few major power sources connected to the grid it's relatively easy to maintain their phase synchronization. As opposed to 'renewables' like solar and wind power where myriads of relatively small energy source machines have to be all kept in perfect synchrony somehow. And if for any reason the grid goes down in a major blackout, getting all those small sources to start up again in synchrony can be extremely difficult. Actually potentially impossible, if you don't have some giant spinning steam turbine generators to 'jump-start' the system.

- They are not at all dependent on the weather. They just keep running regardless of storms, or (worst for 'renewables') overcast windless days. Or ice ages... we'll get to that.

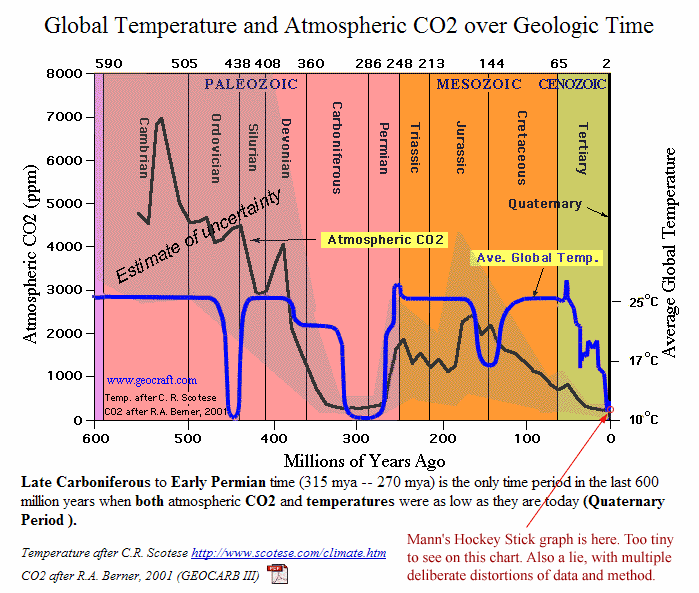

- They free up Carbon Dioxide to the atmosphere, that was lost to the environment aeons ago during the carboniferous age, when most of Earth's surface carbon reserves were unfortunately buried (becoming coal) — effectively removed from the biosphere. Yes, you read that right. You've been taught by contemporary media that 'CO2 is a pollutant, an evil thing, cause of Anthropogenic Global Warming (AGW)', and so on. These are actually lies, an ideologically motivated campaign of deliberate deception and non-science nonsense.

I'm not going to try to explain the entire Global Warming scam here, just provide links. However here are some questions you may wish to pursue. Finding the answers to these will surprise you:

- What was the level of atmospheric CO2 around 1900?

- What is the atmospheric CO2 Level now, around 2000-2020? Gosh, it went up around 30% since 1900! That's terrifying, right? But wait....

- What has been the running average level of atmospheric CO2 over the roughly four billion years history of life on Earth? Surprised yet?

- What is the level of CO2 in the air, below which most multi-cellular plants starve to death? Of course you knew photosynthesis is a process by which plants extract carbon from CO2 in the air, using sunlight to break the carbon-oxygen bond, to build their tissues. And that without enough CO2 plants die. But what's the lowest CO2 level they can survive? When you answer that you should definitely be surprised.

- How often and for how long did atmospheric CO2 ever go as low as it is at the moment? (Now you're astonished. Maybe starting to get angry about being lied to.)

- What do horticulturalists feed into the air in their glasshouses, and what effect does that have on plant growth vigor?

- What do plants need a lot less of as they get more CO2, and why?

Back to local matters. The power station presented a sad story. It isn't mothballed with consideration it might be needed in future. It was deliberately and non-recoverably destroyed rapidly after being shut down. Critical major components such as all the special steel pipes from the heat exchangers were cut out straight way. That station is never going to run again. Even more typical of brain-dead official mismanagement, the station had just finished a complete computer modernization of all the control systems, a few months before it was shut down then rendered permanently non-recoverable. The control room is both very impressive, and tragic.

|

|

|

|

|

The first three photos are by others in the group, the rest are mine. Sorry mine are not very good. No outside shots because the tour was at night, and the tour was quite rushed so little time to compose anything. Also there were a lot of people in each group, which made uncrowded views rare.

|

|

|

|

|

|

|

|

|

|

What takes all this beyond political stupidity into the realm of deliberate murderous societal sabotage, is that Earth is right now heading into the first years of a new Little Ice Age, likely to last at least a hundred years. Much like the Maunder Minimum aka Little Ice Age of the Middle Ages. We are going to desperately need big, coal fired power plants. But noooo, the Warmists are trying to shut down and destroy as many as they can get away with. Which they wish was all of them.

The core Warmist conspirators know perfectly well there has been no global warming for the past 18 years, and now a solar minimum is beginning, with global temperatures heading down rapidly. So they have shifted tactics. They dropped the term 'AGW' (anthropogenic global warming) years ago when they realized it was too academic and most of the public couldn't even pronounce anthropogenic let alone get concerned about it. Gradually they dropped the term 'global warming' (because there hasn't been any for around 18 years now and it's getting harder and harder to fudge the data to make it look like there is) and substituted the term 'climate change.' That let them also blame human industry for all the exceptional unseasonal snows and frosts starting to occur worldwide. Quite recently they're falling back to an even more absurd insult: 'climate change denier.'

Ha ha... typical propaganda trick; accuse your opponent of something incredibly stupid, and hope it sticks. But I don't think anyone fails to understand the Earth's climate changes quite radically, always. It's an intrinsically chaotic system on it's own, plus it's driven by the Sun which is a variable star.

What's really hilarious about the 'climate change denier' insult, is that the Warmists themselves are the ones pretending the climate is normally unchanging, and it's just us, modern industrial man and 'our nasty CO2' that are causing the first ever dramatic change.

What's really hilarious about the 'climate change denier' insult, is that the Warmists themselves are the ones pretending the climate is normally unchanging, and it's just us, modern industrial man and 'our nasty CO2' that are causing the first ever dramatic change.

But no... that's the bullshit.

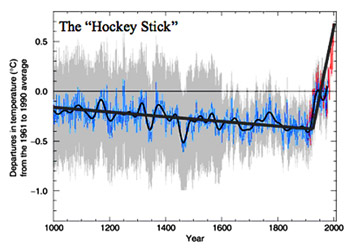

Search for Mann's Hockey Stick for a fine example of everything wrong with AGW data misrepresentation (aka lying.)

Better yet, do separate searches using google vs independent search engines like duckduckgo. Notice the difference? (Google/Alphabet is a component of the matrix that pushes AGW.) You'll also observe there are two radically opposed camps. One promotes the 'hockey stick' illusion, the others point out its many serious factual flaws. Bear in mind the CRU emails leak exposed Mann and his collegues discussing how to distort the historical data to 'hide the decline' and eliminate the medieval warm period. Mann's intentions were dishonest — yet this garbage is still peddled by the Warmists as fact.

I consider myself a conservationist, well aware of the many ways in which humankind exerts harmful influences on Earth's ecosystem. Pollution, overpopulation, habitat loss, species extinctions, ozone depletion and so on are all very serious issues, and we must get our act together on these. Up until 2008 I had been accepting the growing chorus of concern about CO2-mediated AGW, as another of these real and serious issues.

I consider myself a conservationist, well aware of the many ways in which humankind exerts harmful influences on Earth's ecosystem. Pollution, overpopulation, habitat loss, species extinctions, ozone depletion and so on are all very serious issues, and we must get our act together on these. Up until 2008 I had been accepting the growing chorus of concern about CO2-mediated AGW, as another of these real and serious issues.

Then I came across this chart, here: http://www.geocraft.com/WVFossils/Carboniferous_climate.html

Can you see the problem? It struck me immediately. There's simply no way for the fundamentals of AGW, and this chart to both be true. They are logically incompatible. One or the other has to be either wrong, or a lie.

So began my awakening to possibly the most enormous, villainous and demented scam in the history of humankind. It turns out the chart is true, and AGW is a deliberate lie by a specific group of people, for a specific objective. Finding out who and why was quite an adventure.

There's a lot of reading in that AGW links list. Or if you want to focus on Australia's electricity grid fragility and ongoing destructive planning stupidities due to ideologically motivated over-dependence on unstable 'renewables', please read the excellent joannenova site. Combine the government energy policy cluster-f*ck with the government deliberate policy of forced overpopulation via mass immigration, and one could be forgiven for concluding those bastards are deliberately trying to crash the nation back to pre-industrial barbarism.

But this is not about that story either.

Around two months passed after the Lithgow trip. Other explores, refresh cycles on various projects (incrementing but rarely finishing as usual) and random stuff. A few selected photos below; little point explaining them.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

On Sunday 20180630 Nick the searchlight guy phoned. Turns out we have more interests in common than just carbon rods. Also as it happens my last old (in both senses: lifelong and similar age to me) friend and only friend also into electronics, died last year. That's one reason my noblog posts have been sparse lately. I started writing some articles related to his passing, and so far have been unable to finish them. Sigh.

Anyway, new friends are good.

Turns out the loose carbon rods I have are exactly the right type for that searchlight, so they're his. There's also the detail of where I got those, and whether the many more that were lying around are still there. This to be pursued. But more urgently, he has an engagement to operate the searchlight at an official event up at Richmond air force base quite soon, and there are some problems.

Mainly mechanical issues. The structures that hold the carbon rods and transfer the arc current to them, naturally get very hot in operation. They appear to be the original parts from WWII era, and are in a bad way. Nick had hoped he could get them to hold together with some simple attention in his workshop. But his health is poor at the moment, and his workshop has got a bit out of hand. I offer to help, both with sorting out his workshop, and fixing the searchlight.

Ha ha, my intention was to do these for free, since he's interesting to chat with and I think the searchlight is cool. But he's nearly as chronic a collector as me (part of the problem with his workshop) and possibly related to his health troubles is in a generous mood. So he keeps giving me stuff. I'm not one to turn down nice things, and so acquired a whole new set of tech-antiques and potential unfinished projects. I don't feel bad about this, as the workshop tidying was quite a lot of work.

Then there's the searchlight parts. My metalworking resources are a bit more extensive than his. For me, making all-new replacement parts was feasible. So that's what we did. In stainless steel rather than mild steel, which should result in better heat resistance than the originals.

This wasn't complicated, plus I was working with a close deadline so not very many photos.

|

|

|

|

1. I had a bit of scrap stainless steel bar that was slightly over the correct width to match the carbon sleeves. After cutting to length, here milling it down to the right width.

2. The two new stainless steel holder plates, with the most damaged of the original steel ones. The carbon block has two locating holes, that the heads of the screws fit into. I'd machined the hex heads of the screws down to fit the carbon block holes. The most difficult part was tapping M4 threads through 10mm thick stainless. The taps could cut the stainless without blunting, but once several of the thread teeth were biting in, the torque required to keep cutting would have snapped the tap shaft. Cutting threads in stainless is difficult, and in the past I'd only attempted it with thin pieces.

One solution would have been to make the hole oversized, so only shallow threads were being cut. Which didn't seem like a good idea in something that would be running at near red heat for a long time. I wanted full thread profile.

This almost stumped me. Till I found that by alternating back and forth between taper, intermediate and bottoming taps, each one could be advanced a couple of turns before jamming. The profiles are different, so each one is cutting a slightly different section of the desired thread, and can do it without snapping the tap.

So, 10mm of fully threaded hole in stainless. Woo hoo!

3. Side pins added. Again M4 screws, thicker than the pin screws on the thin old steel plates. I used button head screws, with a short piece of stainless steel tube as a sleeve for a diameter to fit the existing retaining clips on the searchlight.

4. Closeup. The old steel plate end was melted when a rod was allowed to burn too short, and the arc played on the steel mounting.

|

|

|

|

|

1. With the new stainless steel replacements finished, and no way to give them a trial run in the searchlight, we decided it might be a good idea to also restore the old plates as much as possible. Just in case there was some problem with stainless steel in this application. Like for instance some of the arc current is applied via secondary cables to those locating screws, and stainless steel has a relatively high electrical resistance. Might it get even hotter than the steel plates, and melt?

So I MIG welded steel back onto the melted-away end of the really bad one.

2. Then chopped that blobby mess back to about the right size with a cutting disk, then used a grinder to go the rest of the way to right-sized.

3. On one, retaining the original side pins wasn't an option since besides being bent by the spring tension while hot enough to be a little soft, Nick had sheared off one of the screws while trying to unscrew it. Which meant I had to drill out the remainder, hence go to a larger screw.

The trick to extracting small screws that are rust and heat siezed, is to slightly deform the bulk of the steel into which the screw is locked. Place the thing on an anvil, and strike it non-delicately with a ball peen hammer right over the screw line. This cracks the oxide in the hole. Spray with WD40, grab the screw with vicegrips, and see if it can now be worked slightly back and forth with light torque. If not, more hammering. If it can, just work it gently till the WD40 seeps in and the oxide gets more broken down. It will gradually allow more angle of turn, then screw right out. Should never need much force, so doesn't shear off.

Since these plates were too thin for an M4 side screw, I used stainless M3 button heads, and had to machine sleeves for them. Here parting off a sleeve from a bit of stainless steel rod. The brass wire is just to stop the sleeve from flying away and getting lost when it pops off.

4, 5. End result. Not pretty, but workable. In the event the stainless ones were fine, so these spares weren't needed.

Some more photos of the searchlight and internals:

|

|

|

|

|

|

|

|

|

|

|

|

That was fun! It's important to keep fine examples of important periods in history, in actual working condition. Static exhibits in museums are all very well, but nothing beats seeing the thing in operation.

It looks like I'm going to be helping keep this one going in future. Happy to be of assistance.

And then... isn't it funny how things come in threes?

Update: 20190303 Bogie Axles

In March of 2019, half a year after the above, my friend is preparing the searchlight for a trip to the annual "Corowa Swim In" — a week long gathering of 'Khaki Vehicle enthusiasts.' (Anything military.)

In March of 2019, half a year after the above, my friend is preparing the searchlight for a trip to the annual "Corowa Swim In" — a week long gathering of 'Khaki Vehicle enthusiasts.' (Anything military.)

Held in the town of Corowa, NSW, Australia, on the Murray River.

See https://www.corowaswim-in.org/

I hadn't heard of this before I met 'the searchlight guy' last year, and I'm cursing that I can't go because my old car (1993 Subaru 4WD) is currently in a repair shop and won't be ready in time. The event runs Mar 11th to 17th.

Next year... if we're both still alive then. At our ages, nothing is certain.

Among the preparation work on the searchlight, it needed repairs to one of the four 'tank tread' bogies. There's not many days left, so I offered to do this small job.

|

|

|

|

|

1, 2. The searchlight had been 'randomly maintained' for decades before my friend got it. His career was as a cinema projectionist, from very early days and so he has experience with carbon arc lamps. These things are a bit tricky to run, and so his is now the only known functional WWII searchlight in Australia. There are several other searchlight hulks in existence, but they are all in the posession of 'institutions' and so of course are utterly neglected and broken. It takes a dedicated and technically skilled individual to keep one of these things going.

Anyway, someone in the past had replaced axles on some of the bogies with wrong dimension ones. We have a couple of original axles, but they are rusty, in a box of junk. This is one of them, but was solidly rusted into one of the 'wheels'. Here I'm extracting it. The usual method with rust: heat, WD40, hammering, and extreme force. I was using a crowbar against those G-clamps, to forcefully rotate it. Initially even then it would barely move, but with persistence the rust lumps locking the wheel to shaft crumble and work free.

3. With a sample axle (leftmost of the five here) I could get the dimensions, thread type, etc. Of course it was made in imperial units. 5/8" rod, threads are 1/2 inch BSW (Whitworth) 12 gauge. I'd gone and bought 3 meters of 5/8" bright round steel rod, a 1/2"W12 button die, and 20 matching nuts.

Cut and machined down the ends of four new axles. This photo is after cutting the threads on one of them. Just a check. And a rest... it's quite hard physical effort cutting 1/2" threads with a button die, and it was a hot day.

4. One of my new assistants. See Kittens Carnival.

5. Getting back to work. There's no way I could start this large a thread with the button die in a plain hand-held tool. This thing is a holder I made some time ago, that keeps the die straight using a centering shaft in the lathe tailstock. The lathe chuck is locked, and all the cutting done by rotating the tool by hand. The pipe wrench is essential, to get enough torque. And even then it's hard. Also I found I had to apply end pressure with the tailstock to get it to cut properly at the start, rather than just produce a no-threads taper on the shaft.

I should weld something onto this tool to take a lever or big spanner. The pipe wrench method isn't ideal.

|

|

|

|

|

1. Another one done. Running out of time on this day, since the plan was to get that one defective bogie fixed and back on the searchlight today. So I just left the two unthreaded axles for some other time.

2, 3. The searchlight. The bad bogie is the leftmost one, currently in place but awaiting new axles.

In the background is another searchlight, that was ruined beyond restoration by previous owner's neglect.

4. Bogie removed, axles removed.

5. Back on, with the new axles. The white shading is spray-on lithium grease. Not my idea.

Another bit of repair it needed, was in the gear housing to gradually feed the long carbon rod into the arc as it is consumed. Some jerk (previous owners) had forced a shaft to rotate and sheared off a taper pin fixing a gear to the shaft. Getting the sheared off pin out was my job. All fixed now, but we were rushed and I didn't take photos.

There's also a gear in the same structure with badly damaged teeth, that I can make a replacement for. But for now it still works, so that will be some time after the Corowa event.