This is a record of my attempts to buy another (bigger) second hand lathe. The first attempt from Gumtree seller 'NICK' was a disconcerting failure. There were some adventures and surprises on the way, and now a happy ending. Maybe also some more surprises yet to come.

Background

I need to machine some 310mm diameter parts for a vacuum chamber experimental rig. Unfortunately my existing lathe (9" Sheraton Model A) is far too small for this work. Getting the parts made commercially is not a viable idea because each one would cost a great deal, there are at least two different ones required, and as this is an experimental setup it's very likely I will need to modify or even redo them in future as the system evolves. Also the test chamber end doors (2 of them) are thick aluminium disks of 510mm diameter. Conceivably I might need to make new ones of those at some point.On general principle I'd rather spend money for capability to make a thing myself, than on buying the thing.

So, I've been looking for an old second hand lathe, as cheap as possible, that has swing clearance (distance from spindle center to the bed) of at least 170mm, preferably 300mm. Plus at least one big faceplate, or better yet a range of faceplate sizes.

The vacuum system project is stalled until I find one.

I'd been looking for a few weeks, before:

20170907 Saturday

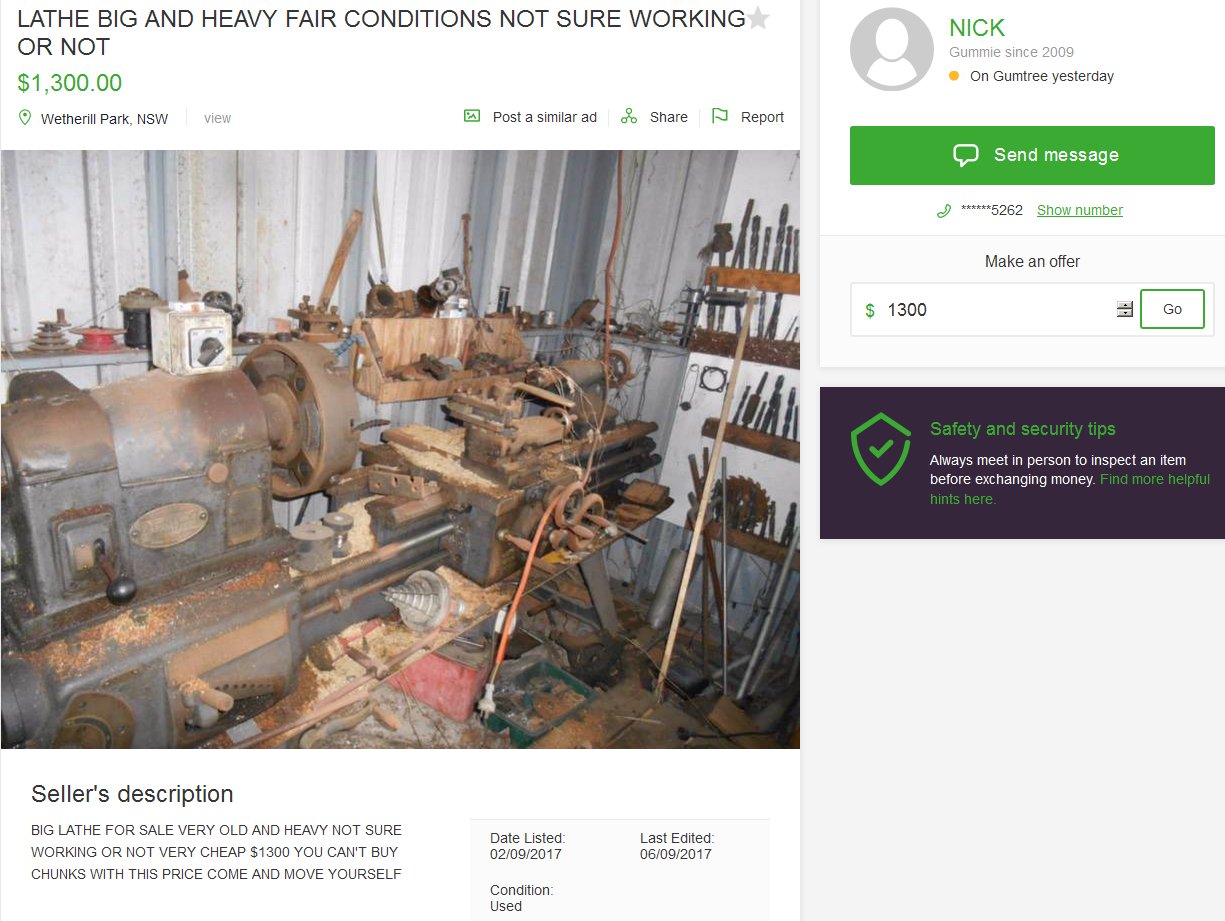

Found this gumtree listing:

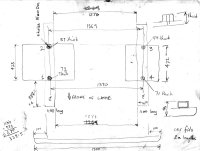

Screenshot from Gumtree. Details below:

URL: https://www.gumtree.com.au/s-ad/wetherill-park/miscellaneous-goods/lathe-big-and-heavy-fair-conditions-not-sure-working-or-not/1158543932 (Later: It is no longer listed.)

LATHE BIG AND HEAVY FAIR CONDITIONS NOT SURE WORKING OR NOT $1,300.00 (No offers made yet)

Seller's description: BIG LATHE FOR SALE VERY OLD AND HEAVY NOT SURE WORKING OR NOT VERY CHEAP $1300 YOU CAN'T BUY CHUNKS WITH THIS PRICE COME AND MOVE YOURSELF

NICK ph 0419435262 Wetherill Park, NSW

Date Listed: 02/09/2017 Last Edited: 06/09/2017

All gumtree listings by NICK: https://www.gumtree.com.au/s-seller/NICK/31359368

This looked interesting. The lathe appears in terrible condition, neglected, rusty, covered in some rubbish (sawdust? Clay?) disused for a long time (dead vines still draped over it) and apparently everything in chaos and disorder.

But it's clearly large enough for my purposes, and could probably be cleaned up and repaired. Some lathes have a removable section of the bed (called the 'gap'), and this one appears to have that part removed.

Overall the poor condition is a plus for me, since it equates to a lower price. Or it should.

Questions:

- Where is the removable section of the bed? It's critical, required for most lathe use, impossible to obtain a replacement, extremely difficult to make an adequate replacement due to essential precision alignment and material (cast iron) compatible with the slides of the saddle.

- There's no faceplate visible in the one photo. Is there one with it? If not, this lathe is no use to me.

- That's a 4-jaw chuck. Inconvenient for most general use. Is there a 3-jaw chuck with it?

- All the other usual: does it actually work, 1 or 3 phase motor, condition of bed and screw feeds, etc.

Then there's the listing text. It's very illiterate sounding, almost incoherent. All-caps, no punctuation, strange phrasing. What does "you can't buy chunks with this price" mean? Is he trying to say scrap iron would cost more? It doesn't sound like a '2nd language' issue, more like some kind of conceptual glitch. Odd.

Which brings us to the price he's asking. It's completely absurd. Some people do tend to put unrealistically high prices on things, as a tactic. But $1300 for this is so far into unrealistic, it raises that sanity question again. It's the same with all his other listings too. He wants near-new prices, for old, rusty, maltreated relics. In general, what kind of person put these adverts up? Is he really somewhat detached from reality?

Only one way to find out. Here's my first Gumtree message to him, and the resulting exchange:

20170907 Thursday evening

From: Gumtree Australia

To: ****@optusnet.com.au

Subject: Copy of your reply to ad "LATHE BIG AND HEAVY FAIR CONDITIONS NOT SURE WORKING OR NOT"

Your reply to "LATHE BIG AND HEAVY FAIR CONDITIONS NOT SURE WORKING OR NOT" has been sent successfully. Reference Number: 1158543932

Hi NICK,

About your "LATHE BIG AND HEAVY FAIR CONDITIONS...".

Just curious if you are serious about that price? It's very old, very rusty, you don't know if it even runs, and someone has left it piled with clay(?) or something for years.

I saw the ad because I'm looking for a very cheap old lathe, to do just one thing my current lathe can't do due to not enough swing clearance. Currently just looking around. Conceivably this lathe might do the job, but I wouldn't make an offer till seeing it. And that price is completely unrealistic. You know heavy scrap iron has nearly negative value, right?

Subject: Re: Guy replied to your ad "LATHE BIG AND HEAVY FAIR CONDITIONS NOT SURE WORKING OR NOT"

To: ****@optusnet.com.au

From: NICK via Gumtree

ok what is you offer then?

From: Guy <****@optusnet.com.au>

Subject: Re: Guy replied to your ad "LATHE BIG AND HEAVY FAIR CONDITIONS NOT SURE WORKING OR NOT"

At 10:50 PM 7/09/2017 +1000, you wrote:

>ok what is you offer then?

I'd need to see it before I'd commit to an offer. Since really what's at stake is a lot of hassle arranging transport, then getting it working and cleaned up. Don't know if it's even worth that effort, till I see it.

Actually, I can probably save us both some time, by mentioning I wouldn't pay more than around $200 for that. Not an offer, just giving you an idea of what I think from the photo. I suspect that won't match your expected range.

But I get the feeling you had little to do with this machine before. That and the other small one you've listed have been neglected for a long time. So perhaps you just guessed a price?

I suggest you should have a look at other adverts for lathes, to see the price range of nicely working ones.

Far less than what you are asking. Some are free. See:

Several for $1. (They just want to get rid of them, it's the MOVING that costs!)

Also this for $500 https://www.machines4u.com.au/view/advert/Hitachi-Seiki-Seiki-5D-turret-lathe/380009/

And those don't sell.

Guy

Incidentally I eventually found out those $1 listings were just click bait. They exist, but that seller does not posess them. They are part of an upcoming auction, with starting prices of $1. More on that later.

20170908 Friday

Subject: Re: Guy replied to your ad "LATHE BIG AND HEAVY FAIR CONDITIONS NOT SURE WORKING OR NOT"

To: ****@optusnet.com.au

From: NICK via Gumtree

when would you like to see it?

From: Guy <****@optusnet.com.au>

Subject: Re: Guy replied to your ad "LATHE BIG AND HEAVY FAIR CONDITIONS NOT SURE WORKING OR NOT"

At 08:48 AM 8/09/2017 +1000, you wrote:

>when would you like to see it?

How about this Sunday?

Let's say 10am.

If that doesn't suit you, let me know when you'd prefer. I'm retired, could come weekdays too.

I'll need your address. I'm coming from ******* (near Bankstown.)

My contact numbers:

mo: 0423 26**** (but usually don't carry it with me)

ph: 9771 **** (where I usually am)

Regards,

Guy

Subject: Re: Guy replied to your ad "LATHE BIG AND HEAVY FAIR CONDITIONS NOT SURE WORKING OR NOT"

To: ****@optusnet.com.au

From: NICK via Gumtree

Sunday Ok but 11 or 12 be fine for me you call me before and I send you my address 0419435262

From: Guy <****@optusnet.com.au>

Subject: Re: Guy replied to your ad "LATHE BIG AND HEAVY FAIR CONDITIONS NOT SURE WORKING OR NOT"

At 09:13 PM 8/09/2017 +1000, you wrote:

>Sunday Ok but 11 or 12 be fine for me you call me before and I send you my address 0419435262

Ok, got that. Too late in evening to call now, will call you tomorrow.

Guy

Hmm, well being a 'man of few words' isn't unusual. And being cagey about the address is fair enough I suppose.

20170909 Saturday

Around 1:30pm I phoned him. First time we've spoken. He sounds as if he possibly has a cognitive disability, or is just very old and unreactive.It was difficult to transcribe the address. He has some accent, and he kept saying the street name rapidly and indistinctly, so obscurely that at first I couldn't even repeat it, let alone spell it. Finally after about 4 cycles of him saying it (the same each time) and me asking him to say it slower or spell it, I got it. #38 Beckenham St, Canley Vale.

Which isn't the same suburb as he has in the listing. Hmm... And I'm starting to have an impression he's difficult to talk with on the phone.

One good thing; it's not so far. Near the grey elephant, intersection of Hume Hwy and Henry Lawson Drive.

20170910 Sunday

Nick called me around 9am on my landline, shortly before I'd intended to phone him. He wanted to check I was coming there today, and insisted I give him an exact time for my arrival. He didn't say why he wanted the time to be exact, which made it seem a bit odd. Turns out the reason was he doesn't live there.I arrived there at 11:30am, as arranged. He had the garage-workshop open. In person he's a lot more communicative than on the phone and text. Seemed fairly normal. Late middle age, relates a story of family health issues. The workshop was his father-in-law's, who died a year ago. The garage has to be cleared out, hence selling all the contents on Gumtree.

Since I have my own family and personal health issues and recent death of a friend we commiserated. I explained my requirements for an old lathe, and we discussed the condition of this one. He showed me the various accessories for it lying about the shed, all of which are included in the sale, though not being pictured in the advert.

The minimal effort he's putting into these sales may be due to other time demands. Though I think there's more to it than that.

I found that the 'stuff' all over the lathe is dry sawdust (ie not oil soaked.) Wood dust in general is bad for exposed bare steel, since it tends to soak up what oil film there is, and promote rust. But here it doesn't seem to have caused much harm.

There are several big face plates, hooray! A 3-jaw chuck too. But very sadly, the removed section of the bed is just plain missing. He's never seen it and I can't find it anywhere in the shed. Without it the saddle can't come close enough to the chuck for normal working. Can only operate by winding the small slide right out, which is highly dubious and undesirable. Greater flex in the cutting bit results in a poor quality finish of the machined surface.

I made the points that I'm poor, currently really only have $300 available to buy an old lathe. Plus in this one's age, condition, and missing the crucial bed section, it's not worth much more than that anyway. I actually had $500 in cash on me, and only a few dollars in the bank, but needed to keep around $200 for some car parts, to get my Subaru to pass registry inspection. It's been out of rego for a while so putting that off more is bad. At the moment I'm driving a borrowed small car, and that can't go on for long either.

We seemed to be getting along OK, and he volunteered the price of $500 for the big old lathe and all its accessories. But that was as low as he'd go. Since really the money was for the mother-in-law, and she'd feel cheated if less. Fair enough. So I accepted, warning him that I couldn't pay that now but would have to borrow $200 to make up to $500. I'd be able to pay him tomorrow, I thought.

He agreed. I got in my car and started driving away, but got only around the corner when I had a better idea. Drove back, he was still there. I said I can phone my mother now, ask if I can borrow $200. If yes, I can give him a $200 deposit now. Phoned her and she OK'd it.

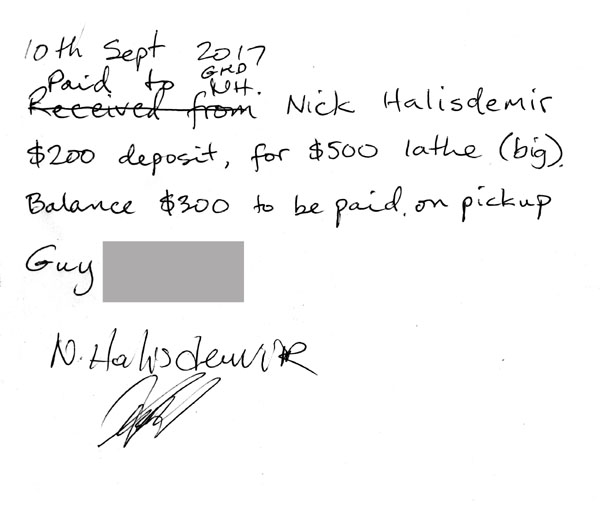

Then I hastily wrote out a receipt for the deposit of $200 for the "big lathe", with balance to be paid on pickup. I was excited and rushing, so goofed slightly with the wording — and then signed my own name under the text, when it should be just Nick's signature. Anyway, I gave him the $200 in cash, he signed the receipt, I corrected the wording, and we both initialed that change. Really the mistakes were a result of me writing it, instead of Nick. He should have written it, as the receiver of the deposit. But he didn't offer, and I assumed he's 'not comfortable with writing', much as in his Gumtree listings.

After that we both left.

Here I'd made two serious mistakes. I should have given him the full $500, got a receipt for completed sale, and then immediately loaded all the easily portable parts (faceplates, chucks, keys, tool posts, etc) into my car. But I was feeling excited and happy, to (I thought) have solved my machining problem and acquired a suitable lathe. I did not anticipate the kinds of problems that next arose.

I also should have taken detailed photos of the lathe and all visible accessories. But I'd left my camera in my car, and assumed I'd be collecting the lathe pretty soon anyway, so no point. Sigh.

For what's it's worth, here's a list of the accessories, from memory.

20170911 Monday

Nothing much. I can't recall if I had any contact with Nick this day. I think not. In the afternoon I did my old mum's weekly chores and shopping as usual on Mondays, and also picked up the extra money from her.20170912 Tuesday

We had made arrangement for me to go to Canley Vale at 10am Tues 12th, to give him the remainder of the money, sort out lathe pieces, take measurements and so on.

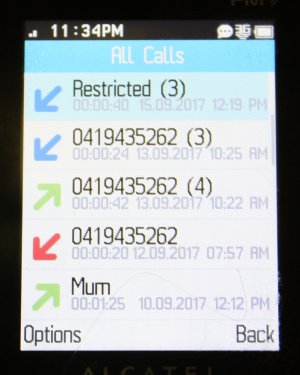

At 7:57am, he called me. I missed it but he left a voicemail. He says he's been up all night at the hospital with mother-in-law, cannot come to the meeting today. Then he gets very strange, and mumbles about how I should "Not come, I don't know, stay home, do something else..."

At 7:57am, he called me. I missed it but he left a voicemail. He says he's been up all night at the hospital with mother-in-law, cannot come to the meeting today. Then he gets very strange, and mumbles about how I should "Not come, I don't know, stay home, do something else..."

(I'd hoped to make a file copy of this message and include it, since it's so odd. But my phone service Optus deleted the message before I had a chance to do it.)

I phoned back, missed, he calls me again soon after, around 8:20am.

I say I have the money to give him, want to arrange another time to come give it to him, pick up the accessories, measure the lathe, etc as preparation for moving it once I've arranged a truck. I suggested tomorrow. He doesn't want to agree to anything. He starts insisting it should be picked up all in one day. Claims if I take the parts on the first trip, then I'll just leave him with the lathe body, so he then can't get rid of it.

I'm astonished, think that's an insane idea but I don't say that to him. Just assure him I need the lathe, and asap. I try to explain the need to measure the base, identify lifting points, etc, to make plans for lifting and moving it.

This makes no impression on him. Which is quite unreasonable as moving heavy machinery is not something to be attempted without a plan. See this article on methods: http://www.lathes.co.uk/lifting-a-lathe/.

I say well, hope you have a good sleep. I'd like to get things moving, maybe could he phone me tonight to arrange the next meeting, when he is rested? He is non-commital. I get the impression he won't phone. Conversation ends, with no arrangement for when to do the payment and begin pickup.

It leaves me quite worried. His insistence on the 'single trip pickup' for a maybe 2-ton lathe and all the accessories scattered around, is bizarre and unreasonable. But does he really believe it, or is he dissembling? Or just plain insane? I start to get a hunch he might be backing out, or just impossible to deal with.

Even more worrying, his listing for that lathe is still showing it as available for purchase. Did he just forget to take it down now it's sold to me? Too tired, didn't go online today perhaps. But he really should have taken it down on Sunday, after I put a deposit on the agreed sale.

20170913 Wednesday

At 10:22am - 10:25am, we both call each other almost simultaneously. I missed his first call, called him and was leaving a voicemail as a beep announces his incoming call, missed. (New unfamiliar phone, I didn't then know what the beep meant.) He calls me again, asks me if I'm free to come that morning. I say "yes please!" thinking he means to proceed with the payment and pickup. I say I will leave now, takes about 20 minutes to drive there. I load all the gear in the car (mover's cloths, tools, camera, writing pad, have money in pocket.) I'm very happy!Traffic is good; I get there pretty quickly. Strangely, I find him sitting in his car parked on the street out front of the house. The garage is not open. I get a sense this is not going to be what I expected. I have to park on the other side of a big earthmover truck parked in the street.

I get out, start walking back to Nick's car. He gets out too, walks to me on the street (not to the house gate.)

He asks me how I am, I say OK, but how about you? How is your mother in law? Did you sleep well?

As I'm asking, he isn't answering, just pulls out some cash and hands it to me. Then turns and starts walking back to his car. I quickly count it, it's $200. I'm starting to go into shock. What is this!? He's... dropping the deal! Oh no!

I walk after him, upset, asking him what he's doing, why, and so on. He makes no relevant response, just some muttering about how some relative is on dialysis, he doesn't have time, etc. He gets in his car, and I'm standing by the driver's door, literally begging him to stop, talk to me, tell me what's the problem. I have a pretty strong hunch, he's just dropping the deal because he was offered a better price, I thought. He starts the car, and ignoring me, drives away.

At no time did I insult him or say anything rude to him. Neither on the phone, or then when he was reneging on the deal. In this file I'm being sarcastic, but bear in mind I wrote this after he proved himself to be a dick, by reneging on our agreement while pretending the reason was something other than greed.

When I get home and check Gumtree, the listing for that lathe shows as 'sold'. Leaving 9 active listings.

In chat just now (11:30am) with Gumtree support, they gave this URL to the original listing:

https://www.gumtree.com.au/s-view-details.html?adId=1158543932&uuid=3fe8bcf0-6a3e-48bd-86a9-d2f15f89c29a&cs_call=true

My name is JJ, how can I assist you today?11:34:56 AM

Me: I'd like to report some unethical conduct by a seller.11:35:39 AM

JJ: Ok! Would you be able to kindly give me some details of what took place?11:36:35 AM

Me: Seller listed a large lathe, I inspected, we agreed on a price (lower than his too high listing), I paid $200 deposit and got a receipt. Still to arrange details of moving the machine.11:37:40 AM

Me: Today he arranged me to go there, I thought to pick up accessories. But he backed out of the deal. At least refunded the deposit. But it's been a big hassle. Very shifty guy. I assume someone offered him more, and he broke our deal.11:38:46 AM

JJ: I'm sorry to hear that, Guy. Is this the ad here in question? https://www.gumtree.com.au/s-view-details.html?adId=1158543932&uuid=3fe8bcf0-6a3e-48bd-86a9-d2f15f89c29a&cs_call=true11:39:06 AM

Me: Yes, that's it. Now showing 'sold'. He has alot of other things for sale atm. But would like to warn poeople he's unreliable, lies.11:40:04 AM

JJ: Yup, now that we have this information about this user, we will investigate the situation further and take any necessary action.

We really appreciate you taking the time to write in about this and hope that your future Gumtree experiences are much more positive.11:40:24 AM

Me: OK, thanks. I'm really sad atm. It was a good deal, but he's impossible to arrange pickup details etc with.11:41:19 AM

JJ: I'm really sorry for this, Guy. :(11:41:33 AM

JJ: But, I hope that you do enjoy the rest of your day!11:41:56 AM

Me: K, thanks. You too. Bye.11:42:12 AM

JJ: Cheers mate!11:42:19 AM

One principle I try to follow, is 'don't give up.' Thinking Nick may now be in negotiation with another buyer, and perhaps that might fall through, I thought I'd let him know I was still interested in the lathe. So around 1pm on Wednesday I sent him a Gumtree message via one of his other listings; a small Hafco lathe.

Reference Number: 1158542369

Well that was very disappointing.

I'm pretty sure I didn't do anything to offend you, and I don't believe you'd break the agreement just because I want to do the move in two stages, instead of 'all in one go'. You didn't even give me a chance to explain why that would be necessary. And I don't think you care. Also family illness etc, I really do sympathize, since I too have ill family members and my own problems. But that wasn't a valid reason to deal-break either. If you can't handle those problems AND selling stuff at the same time, then don't do the selling.

1158543932 is showing 'sold' now. So, as I suspected, you just decided to take a higher offer. Forget about our signed agreement. And you lied about it to my face, making weak excuses. "Don't have time", ha ha, but you have time to keep taking offers from other buyers.

OK. Not very nice.

Anyway I'm still interested in the lathe. It suits my needs very well, and I don't bear grudges. So, if your 'higher bidder' drops out, contact me. Maybe by then I can afford to offer more too. I really was hoping to keep you happy.

My email: ****@optusnet.com.au You have my phone number.

And here's my reasons for asking for the huge inconvenience to you of two visits instead of one:

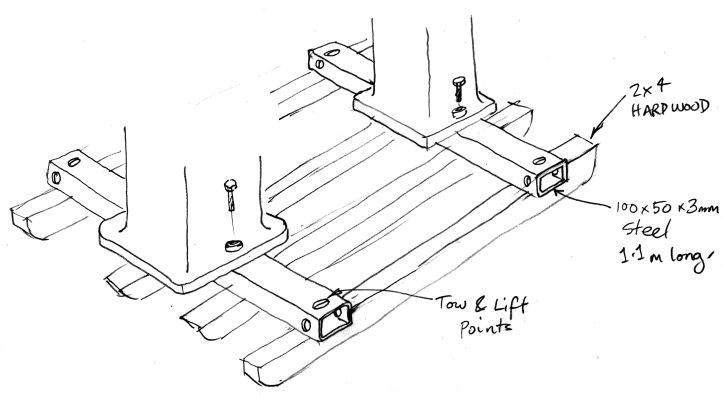

#1. You don't know my place. Today I was going to invite you to see. Basically a truck won't fit down the narrow side drive. So I have to build a sled, to drag the lathe down the side, across some bumpy ground, then into the shed. To build that I needed measurements of the lathe base. Also was going to try measuring the weight, so I can hire a truck with adequate crane.

#2. You are selling other stuff, will be showing others through the shed. Since I'd paid a deposit, signed agreement, etc and had the remaining payment ready to give you, I considered it my lathe. Didn't want portable parts sitting there in the shed while other people inspecting. In case bits go missing or get damaged. Didn't know how long it would take to arrange friends to help, hire truck, etc. Also worried you'd go back on the deal. Ha, ha. Correctly.

As for your idea I'd "take the parts and leave you with the lathe" - well that's ridiculous. No way you could be serious. Just you making excuses to back out, I think.

The really shitty thing is how much work I've done to make a space ready to put it, and discussions with friends about helping move it. Dammit. Thanks a lot Nick. Well, I guess eventually I'll find something else suitable. They're not exactly rare.

Guy

As expected there was no reply from Nick.

A bit later on the electronics forum eevblog I posted in the 'what did you buy today' thread:

20170913 1:20pm

Well, what I didn't buy today, is that lathe I mentioned. Dammit.

Despite having paid a $200 deposit, having a signed agreement of sale and price, and the remainder of the cash in my pocket while trying to arrange a meeting to pay him and start collecting the gear, today the seller back-slid.

I can only assume he decided to accept a higher offer. It's now showing as 'sold'. Though he lied about it to my face, and made feeble excuses.

He did return the deposit, but arranged the meeting to do that on false pretext.

So, if anyone was considering dealing with this guy: https://www.gumtree.com.au/s-seller/NICK/31359368

I'd advise against it. He's shifty, dishonest, unprincipled and very difficult to deal with. Quite far on the odd side.

20170914 Thursday ...

It was surprising how depressed this was making me feel. An old close friend of mine had died one month ago, on the 14th August. Then I'd had a trip to Melbourne 17th to 21st Aug, related to a personal medical problem, and that hadn't gone terribly well. A few other significant things went badly in the last month too. I'd thought I was coping well enough, but suddenly this unexpected setback with the lathe has me feeling suicidal. Rats. I think something to do with the sudden shock of going from feeling great about getting the sale finalized and the move started, to instantly having it all fall apart as Nick handed the money back without any warning. Also ties into my semi-phobia of 'people acting despicably' that I've developed from decades of exposure to Ra's Pol Pot induced PTSD-behavior.Over the next few days I couldn't get anything done. Should be working on my car, putting that Javac vacuum pump back together, finishing off the shed clear-out I'd already done most of to make space for the lathe. But no. Very depressed, motivation totally gone.

20170921 Thursday

A week passed by. I'd noticed that Nick's 'buy them all' listing still included the big lathe, with even a photo of it.

This is the photo set with that listing. The lathe is photo number six.

This is the photo set with that listing. The lathe is photo number six.

But I wasn't sure; was this just a careless oversight on his part?

Or did it mean the lathe really was still there, in the shed, with no other buyer in sight? And maybe there never was any other buyer.

I suspected the latter, but not with much certainty.

His wording in that listing is a real masterpiece:

MACHINERY GARAGE SALE ALL HAS TO GO WORKING CONDITIONS COME AND GIVE ME YOUR OFER FOR ALL OF THEM YOU HAVE TO REMOVE YOURSELF

3 LETHE 2 SMALL AND 1 BIG, MILING MACHINE, 2 WELDING MACHINE, 2 BAND SAWS ONE METAL ONE TIMBER CUTTING, VICE, 2 GRINDERS, BANCH DRILL, AND BIDS, TABS, HAND TOOLS, TOOL BOXES, I WANT SOME ONE TAKES ALL IN ONE GO COME AND GIVE ME YOUR PRICE NICK ******5262 please don't call if you after small cheap pices

Date Listed: 29/08/2017 Last Edited: 06/09/2017

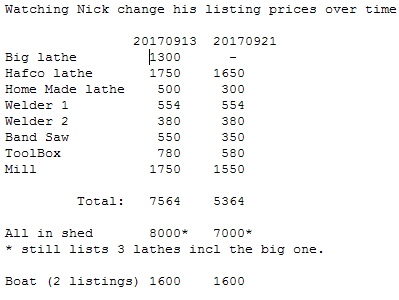

And then... I noticed he'd adjusted some of his listing prices downwards slightly. Nothing is selling, so he's starting to think maybe his prices are a little high.

And then... I noticed he'd adjusted some of his listing prices downwards slightly. Nothing is selling, so he's starting to think maybe his prices are a little high.

The critical point being, he's adjusted the 'all in one' listing down by an amount that implies the big lathe is still included. Which means the mention of it in the listing text and photos, is not an error. It really is still there.

This confirms — he never had a better offer, and it isn't already sold. He just flatly reneged on our written agreement of sale, then removed the specific listing for that big lathe to pretend to me that it was no longer available.

Which means he's worried I could legally enforce the agreement, and demand he completes the sale to me, at the agreed price.

So then, why not do so?

Bah. Quote: "3 LETHE 2 SMALL AND 1 BIG". He's such a jerk, I will look into my legal options.

Notice in the listing text there's his 'take it all in one go' fixation again. For the whole shed-full, that's extremely impractical. A very irrational demand.

Anyway let's give him another chance to do the right thing. I'll even offer a more than reasonable price, above that agreed. I sent him another message via the hafco lathe listing.

20170922 Friday 2:30pm

Hi NICK,

Just reminding you I'm still interested in the big old lathe. I've saved up some more, can offer $800 now. Not going to offer more than that, considering the missing bed part, and that you broke an agreement.

Still not sure why you suddenly backed out of our deal. Probably just decided $500 was too low. Maybe actually had a much higher offer, but I think not. Maybe your mother in law insisted it was too low? Does she understand about the missing part of the bed? That's a really serious flaw, makes it worth a LOT less than a complete lathe. Not supposed to use it with the small slide extended much, it's bad for the slide, puts more play in the cutting tool, not as accurate. I'm pricing in how much trouble it will be to make a replacement. Very difficult, given the rails have to be extremely accurate.

Or, another possibility - I had talked about hoping to get that lathe, on an online forum. Perhaps some joker on there thought it would be funny to call you up and feed you some bullshit, just to kill our deal? Bit farfetched, but I'm struggling for a reason for why your attitude changed so suddenly, between agreeing on the sale, then just handing my deposit back, with no real explanation.

As for your insistence it be picked up in one trip... Sigh. Awkward, but I realize I actually could do it. Could drop it off from the truck in the front of my place, then later make the sled to get it down to the shed at rear. Would not hurt the lathe to sit in the front driveway under a tarp for a day or two. Was thinking I'd have to lower it off the truck onto the sled, but I'm sure I can get it onto the sled later.

I'd appreciate a reply. Even if only 'no', But some explanation for your hostility would be good too. I really don't know how I've offended or upset you, if indeed that's what happened. If it was just that 500 was too low, then say so. Don't throw away a chance to sell it for a reasonable price, for some trivial reason.

Not sure if you may have a personal attachment to that lathe, as you mentioned how you'd been involved with it with your father in law. If that's the problem, I can assure you it would be well looked after here. I take very good care of all my tools. Also the purpose I need a bigger lathe for, is for a very worthy cause. Something that may bring a lot of good to the world, if it works out as I hope. I can tell you about that, if you are interested.

Regards,

Guy

I didn't receive any response to this message either.

Perhaps it's possible his reading comprehension may not be sufficient to understand these messages I send him. But otoh, he was able to at least reply briefly and relatively on-point before he decided to gyp me. Now he just ignores me.

20170926 Tuesday

For the heck of it, an update to Gumtree, via their 'report' email facility:Item: 1158543932

Hi,

I previously reported this seller to Gumtree chat, your agent named JJ.

At that time I didn't have proof the seller had reneged purely because he decided

he didn't like the price he himself had proposed to me. Now it's clear he still

has the item for sale, and only took the original listing down to pretend it had sold.

Incidentally, that listing showed as 'sold' before it disappeared, which since he still

has the same item included in another current listing, means he lied to Gumtree too.

See details here: http://everist.org/lathe/

I've been advised there is no way to force him to honor the written agreement of sale,

other than via lawyers and the courts.

Which obviously, for a sale motivated by finding a low cost lathe, is not feasible.

Unless Gumtree can bring some pressure to bear on this Nick guy.

Do you really want your sellers to be able to get away with crap like that?

Best regards,

Guy

From: "communitysupport@gumtree.com"

Subject: Response to your Case: Further information on a seller who reneged on an agreed, signed sale #0000659740 [ ref:_00DF0505O._5000G1HrUuv:ref

Hello Guy,

Thanks for your email.

I am sorry to hear this, we will take steps to prevent this from happening again on the website as well as investigating their account as this is not the type of behaviour we want on Gumtree.

Unfortunately as mentioned we cannot force anyone into the sale.

We do appreciate you bringing this to our attention and for your patience in the meantime.

Thanks,

Luke

Gumtree Community Support

Ha. A form letter maybe? Well, I didn't expect them to actually do anything, like ban him. More's the pity.

20170928 Thursday

Since I've located a suitable crane truck hire, and now know the costs, I thought I'd send another message to Nick. For him to ignore.Sent via the Hafco lathe listing:

Seriously, you are not going to get a better offer. None of your stuff is going to sell at the prices you imagine. $800 is a very good price for that lathe with important piece missing. Please stop wasting everyone's time, including your own.

This offer stands until I find another suitable lathe. That could be any time. For eg see gumtree item 1157036147, which is in better condition but is in QLD.

As usual, no response.

Summary, as of 20170928

It appears none of Nick's items have sold. The large lathe is still listed for sale in his 'all in one' listing, with his recently adjusted price demonstrating the lathe really is still included, and is still in the shed. He didn't have a higher offer, he just decided $500 was too low. Removed the specific listing for the lathe to pretend (to me) that it's sold.Whether due to his absurd prices and nutty listing texts he's getting no serious inquiries, or whether he acts as weirdly with any potential buyers as he did with me, and scares them off, who cares.

Theoretically, with the receipt I should be able to legally force him to honor the sale. Looking into that I got bounced around between various providers of free legal advice, starting with NSW Dept of Fair Trading. Who referred me to www.lawaccess.nsw.gov.au, and that led to South West Sydney Legal Center, in Liverpool.

Apparently it would require taking it to court. With costs, hassle and delay, for what was supposed to be the quick purchase of a cheap old lathe, it's not feasible. Once again 'The Law' proves itself to be useless for ordinary people.

If I was able to legally require him to comply with the agreement, it would be for the agreed price of $500. On pickup I may optionally also make him an offer of some extra payment on completion of loading, if the lathe has no deliberate damage, he has been cooperative in locating all the listed accessories, and he did not hinder the process of extracting the lathe and accessories from the garage. Such delay would be costly with a crane truck sitting waiting.

I'm resigned to Nick's obstinancy or whatever his mental malfunction involves, resulting in my not getting this lathe. Maybe Nick will find somebody willing to pay the price he wants, or maybe it will just sit rusting in that shed. That would be quite sad. Hate to see once-fine tools being destroyed by neglect. Losing the bed-piece; sheesh! Not even bothering to wipe the machine clean, oil the bare steel surfaces, and put a dust cover over it... demonstrates an appalling level of oafish stupidity, negligence and sloth.

In any case since there's zero chance of my getting that lathe, I no longer care if Nick sees my low opinion of him. This writeup was begun as a private record for my inquiries about legal remedy, now I'm repurposing it as a post in my public NoBlog.

Currently I'm looking into an upcoming auction of a large number of much more modern CNC type lathes. May or may not be affordable for me, but we'll see. I can stretch to a lot more than I'd have paid for Nick's old, broken lathe.

20170930 Saturday

Having saved a shortcut to Nick's Gumtree listings, keeping an eye day to day on how they go is easy. And I'm curious.As of today Nick has deleted his 'all in one' listing. All 8 other listings remain, all the same price as back on the 21st. Maybe it finally filtered through to him that the 'all in one' listing revealed the big lathe is still there. Or maybe he did actually agree on a price with someone and sell it.

20171003 Tuesday

Checked again today, he's down to three ads. One for the two welders, the other two for the same boat; same price, but with different wordings. It would be interesting to know what he did manage to get for the rusty old tools.

Meanwhile I'm busy looking into feasibility of buying a CNC lathe. They turn up in auctions fairly often, but at more commercial prices (ouch.) Having such a machine has been a dream for years, but considering the likely cost and with no specific need, I left it as a dream.

Now it's worth exploring, but I have no experience with CNC machinery at all. Lots to learn, before I'd dare choosing and paying (a lot of money) for one. My other workshop shed has sufficient space, and the necessary three-phase 415V power, though moving a large heavy machine into it will be 'interesting.'

It's a waiting game; which turns up first, a suitable CNC lathe I can afford, or a very old crappy lathe that will do the job?

So far the slow trickle of old-style metalworking lathes on Gumtree hasn't turned up another that meets my needs, while also being old and dingy enough to justify a very low price. Otoh, with the ongoing industrial decline and factory liquidations in Australia, finding an affordable CNC lathe seems like it might be possible.

20171011 Wednesday. The CNC Expedition

It's been a busy week. Last week I'd come across an online auction of an entire huge gearbox manufacturing plant in Albury, on the border of NSW and Victoria. Among thousands of lots, there were around 90 CNC lathes on offer. Could that temporarily saturate the market, resulting in some going cheaply? I have no idea. But even if they all remain out of my price range, an opportunity to see inside a factory like that is worth grabbing.The inspection runs for two days, Monday 9th and Tuesday 10th. Then everything auctioning online over the following two days. It takes at least 6 hours to drive Sydney to Albury, and I wanted to have a full day for looking. So I'd drive down on Sunday, and that night camp out somewhere near Albury. Back in 2012 when I drove to Ballarat, I'd found a well secluded campsite somewhere a little south of Gundagai (I think.) But if I made notes of the directions to the spot, which side road off the Hume highway, etc, I've since lost them. Despite trying multiple times I can't jog my memory using google maps.

So that spot is out. Besides, I recall the last section of that road was rough. Fine for my old 4WD Subaru, but iffy for the little front wheel drive city car I'm driving atm while the Subaru is under repair.

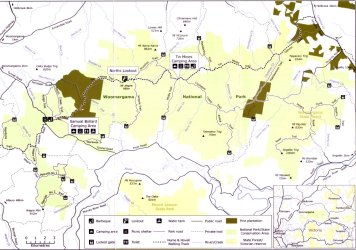

There's always somewhere to camp off highways, but it's nice to have a destination. Looking at the maps, Woomargama National Park seems likely. Sunday morning I packed the car and left at 9:30am. A little later than I'd hoped, but still OK to hunt for a campsite well before dark.

Now, everyone else in my family has been aware for a week that I'd be going on this trip, in this car. I'm driving the family 'spare' third car, since mine is off the road atm. Also this car has to go to smash repair right after I return, to fix a slight ding in the rear where a truck rolled slowly into it due to the truck driver getting distracted while stopped, and taking his foot off the brake. Also I'd said goodbye shortly before leaving in the morning. So you'd think there would be no surprises.

An hour south of Sydney, on the Hume, my phone rings. It's the ex-wife, demanding in a rage to know where I am. Well, I'm ... nowhere. Pulled over on the Hume in featureless bush at least 100Km out of Sydney to answer the phone. Why do you ask? Turns out my daughter, who recently (at last) got her P plates, has left all of them in this car. Ex-wife screams at me, this is all my fault and she demands I bring them back now. Google 'histrionic personality disorder' as an aspect of Pol-Pot induced PTSD, you'll get the idea.

I say no, sorry, can't and won't. She goes incoherent and then hangs up. Sigh. Their options: a few minutes trip to go pick up a couple more free P plates. Or just draw them on white cardboard with red felt pen, they'll do for 2 or 3 days. Compared to me doing another two hours of driving, just to get back to where I am now, then arriving at destination in the dark and trying to find a campsite.

Apart from that the drive was uneventful.

|

|

I'd planned to find somewhere along Tunnel Rd, but what's this 'Tin Mines Trail'? Is that a road?

I like poking around in old mine areas, this sounds interesting.

In Sydney it has been extremely dry for months. No significant rain at all. The country down around the Darling River doesn't look quite as dry as Sydney, but it could obviously do with some rain. By the time I left Holbrook the overcast sky was getting darker. As I turned off the Hume into Woomargama Way, it started raining. By the time I passed the national park entry sign, the rain was heavy. Ha ha, pretty funny.

Actually I didn't mind, and really did think it was funny. Because I have a bit of a tradition of bringing rain when I go camping in dry areas. This always makes me smile when it happens again.

Well, I guess I'll be sleeping in the car. Also I'd forgotten to pack the propane cooker, but I had plenty of food that could be eaten cold. So I was looking for somewhere I could turn off the tarred road, and get far enough into the bush for a peaceful, invisible evening. With a bit of a slope so I can park the car nose-up for comfortable sleeping.

I stopped at the turnoff to the 'Tin Mines Trail'. This turns out to be a rough dirt road rather than a walking trail, with the leaflet and signs insisting 'for capable 4WD and dry weather only'. Looking at the start of it, I agree. But I'm driving a small 2WD city car (which isn't even mine) and it's pouring. So that's out.

Kept driving on Tunnel Road all the way to the junction with River road, taking note of potential camp sites. There is no tunnel, and also much of this park has been burned out about two years ago judging by the regrowth. It's not pretty but in the dark that won't matter.

Drove back to the most promising turnoff I'd seen. This was an old logging road that started up onto the top of a cutting for the Tunnel Rd. I walked up it in light rain. Hmm, it would have been good, except for the massive tree that has fallen across it just out of sight of the road.

Onwards to the next potential, which was an 'obscured entry'. A subtle trail leading off, where someone has pulled multiple dead tree branches across so it looks like just more scrub. I walked up it, and it's perfect. Leads to some large clearings well off the road. It's been a campsite for a long time, but after the bush fire someone wants it to stop being used so hid the entrance.

Well, I'm all in favor of zero impact car-camping. I move the branches, drive in, put the branches back. There's even a slope to park the car on, and part of that isn't underneath any huge trees with lots of high, dead branches that might fall. So that's my 'campsite'. I have about an hour of daylight left, and brief gaps in the heavy rain allow me to set up for the night.

|

|

|

|

|

|

|

1-3. Park entry, obscure turnoff, campsite.

4. Is it a problem staying in a small car overnight? No not at all! The book I'm reading is fascinating. Xenophon's Anabasis - The March Up Country. A true story from around 400 BC of an amazing military expedition. I am NOT going to complain about any lack of material comforts here.

5. For instance, I have a good reading light for as long as I want. This gear is intended for use in a tent, and can have solar panels connected for long term use. But it works fine in a car too. Well, except for the issue of what to hang the light from inside the car. But the land provides... while walking around I'd found a roll of rusting fence wire behind a tree. That gave me a couple of wire hooks.

6. Great literature, simple food, and peaceful patter of rain on the roof. Splendid. Also lots of thunder and lightning for dramatic effect.

7. Fading off. Car seats can be comfortable to sleep in if the car is tilted nose-up, you pad up the foot well with something like a sleeping bag in its cover to bring your feet up, and fill in the V of the seat with whatever — an old jacket or two. Oh, and some kind of pillow for the head.

I'd already written out my todo list for the morning. First order of the day was visiting road freight company Border Express, based in Albury. I really needed to get an idea of what something like a large CNC lathe would cost to transport to Sydney. Not much point inspecting at the auction, if I could not afford the shipping. I had their address and a list of questions to ask.

After that I'd go straight to the auction site, and spend the day there. Possibly I'd also camp overnight again and go back for the second day of inspection.

But actually, the very first thing I'd do in Albury, would be find a newsagent and buy a street map. I use a dumb cell phone, no data plan. Much prefer paper maps anyway. I have a couple of very old 'country town street maps' books with me, but they are way out of date.

20171009 Monday, The Factory

I'd intended to be on the road in the morning by 6:30am. But the night was so pleasant I slept in a little, and didn't leave till 7:15am. At a newsagent in Albury a newspaper headline reads something like "Sydney residents say 'we're full'" Ha ha, no kidding. I get into a conversation with the shop owner about immigration, Islamization, and federal and state politicians. We agree completely. Except perhaps that I predict the ultimate end of those traitorous, money-grasping, stupid, Globalist-puppet arseholes as much more messily bloody than the newsagent imagines. The Greek mercenaries in 400BC knew how to deal with people like that.At the office of Border Express in Macauley St, I learn all their vehicles are Tautliners — curtain sided semi-trailers. No flatbed trucks, as required for big heavy machines. But they give me a list of names of other freight companies that could do it. Names only, no address and phone numbers. They tell me a couple of them are just around the corner in Atkins St, so I go there first. On the way I drive past OneSteel's site, so go in and ask there too. They give me address and phone numbers of two companies on my list. They're not far away, but first, to O'Brien's just along Atkins St.

The customer rep there was extremely helpful. I'm given a quick but clear introduction to freight terminology, methods and prices. Taking notes! Also I learn a new word: demurrage. Plus several small but crucial details, like its best to hire the forklift for unloading at destination for two days, not the one expected day of arrival. Because the truck might have a breakdown on the way, arrive a day late, and then you can't get a forklift.

Overall it's great news as the costs are within my budget for buying a CNC lathe. No need to go talk to multiple companies now.

Next, to the auction site. Coming up to the ASI factory in Kaitlers Road I realise how huge the place is. I knew there were a lot of items in the auction lists, but really... wow.

Online details for the inspection days said 'covered shoes, long sleeve shirt, no cameras allowed.' That last one is odd. Really? No photos allowed, of high cost items customers might want to bid on? Well OK... I'm wearing boots, etc as specified. At the entry gate I'm told the small backpack is not allowed. Sigh, also understandable I suppose. I put that back in the car, bringing only clipboard, tape measure on belt and torch in my pocket. Sign in, get given the site map. The table has piles of about 15 different Lot listings, I take only the CNC lathes list. If I took them all I'd be carrying a half inch thick stack of paper the whole day.

About 15 steps into the building I come across the first surprise. The concrete floor is painted with a cream coloured hard paint, with a surface like glass. And it's oily and wet. With a few steps run-up I can skate along it for some distance. This is the most dangerously slippery walking surface I've ever encountered in any building. Wow. How many falls a year did they have?

Anyway, I don't care. I'll be careful. Next priority question, where are the toilets? They don't know. I get several vague 'over there' directions from different people who all are not sure. I find some in the basement, lights out and taped off 'out of order'. Turning the lights on and checking there's paper and the cisterns do have water pressure, one does the job. Later it turns out there are a few others on the factory level, in the back of the closed cafferteria.

While down in the basement (actually at gound level on one side of the building) I'd noticed everything down here had lot number stickers too. I found the network servers room; five racks full of servers and switches, all with the same lot number. And also, ah ah! In an adjoining room a large three phase 415V Uninterruptible Power Supply. It had the batteries removed, cabinet doors removed, battery wires hanging out, but interesting to me. The electronics rack appears to be complete, and it's not too old a model. I made a note of the lot number.

After that I thought I'd have a 'quick random wander around the factory to get an idea of the layout.' Oh the naivety! The place is vast. Even by the end of the day I still hadn't seen it all, and was still getting lost regularly. There were not all that many people viewing, and only a handful of auction-related staff. So in that almost endless forrest of huge machines taller than a person, the usual state was for no one else to be in sight.

But when I did come across people, they were often taking lots of photos with their cell phones. Hmm... I went back to the entrance and asked if cameras were in fact allowed. No one knew any reason why not, so yes. I went back to my car again for my camera.

|

|

|

|

|

There's really no way to convey the scale of the place in photos. Mainly because although the factory is mostly one big open space inside, I could not find anywhere from which a panorama could capture most of it. There may have been such spots, up on top of structures, but I didn't want to climb things in sight of auction staff, and possibly get myself thrown out.

So these above will have to do. Also, oil everywhere. Including on the steel ladder for this first shot, climbed very very carefully.

1. A view of one small corner of the place. It really is a tiny proportion of the whole.

2. As shown on this floor plan. Red dot is my position, yellow is the photo's field of view.

3-5. Some outside shots. Also could not get the whole view into one photo. I didn't think to take a pano series. Too overwhelmed I guess.

Well then, to work! In the online listings I'd found five machines of the same make and model number, that from the photos seemed like they might be suitable for my specific machining need and workshop space. And I admit, that I thought looked cool — definitely a major factor.

I'd asked the Sydney Okuma distributors a few obvious questions, like were they still in support (yes), were manuals and schematics available (yes), could I possibly make and fix a faceplate to the spindle (possible), and so on. There had not seemed to be any obvious deal-killers, and one very good piece of information — all these machines at that factory have been upgraded during their lifetime. So no firmware updates needed.

But were they really suitable? I had some questions to ask of people who worked with these, but first here's two of the machines.

That's not all CNC lathe. These two Okuma Spaceturn LB250T CNC lathes are built into a 'gantry loader', to form an automated production line.

That's not all CNC lathe. These two Okuma Spaceturn LB250T CNC lathes are built into a 'gantry loader', to form an automated production line.

The two actual lathes outlined at left. By itself one of these would fit in my workshop, but that gantry loader thing definitely would not.

They are Lots 150 (left) and 149 (right.) The gantry sells with Lot 149, while Lot 150 is by itself. Which is a trap!

Apart from plenty of wandering around, the rest of the day (and later) involved learning one bad thing after another about these machines. (For my use.) The order of learning was chaotic, so I'll skip that. Here's a list to get though them quickly.

- The factory was closed nearly four years ago. Since then these machines have sat dead. With some roof leaks. Who knows what faults they may have developed.

- Each machine was bought for a specific manufacturing contract (gearbox parts) and virtually certainly sat there for years doing nothing but that part. This means there may be a lot of wear, and it will all be in the short turret travel range used for that process.

- Every single one of them has a custom 'thing' for a chuck, all different. These were engineered to fit whatever part the machine was bought to make. They are not usable as general purpose chucks.

- Most of them have a fold-down arm and touch sensor for calibrating cutting tool position. But one of them does not. More on that later.

- Even with that arm in the 'stowed' position, it looks like it would be in the way for mounting a face plate. And there's nothing can be done about that, except mount the faceplate further out from the spindle. Thus losing some machining space.

- For large diameter rings like I need, the limiting factor seems to not be the spindle center to bed distance, but the clearance of spindle to tool mounted in the turret. Hard to tell if it would be enough, but I suspect not.

- They are bearably narrow in width, but much deeper than I expected. Also there needs to be working access at the back, and that's where the chip conveyor sticks out too. It would be a squeeze in my workshop.

- A really big negative. Looking at youtube videos of CNC lathes, I'd got the impression that tool turrets in general have the ability to mount milling cutters that spin, driven by internals in the turret. Turns out more modern CNC machines often have that, but these ones do not. Static tooling only.

- Also, I'd seen machines in which the spindle can either spin at speed, or index to fixed position with fine resolution (to allow milling or drilling using an active cutter in the turret), or can rotate slowly under precise angular control (again for complex milling.) But no, not these ones. The spindle just spins, nothing else. I could live with that for my immediate need, but it's a limitation for future potential work.

- Whatever is used for a chuck, there's a mechanism for closing the chuck automatically. This involves a 'draw bar' running down the center of the spindle shaft. And that means... there is no 'spindle bore', ie you can't feed in bar stock down the spindle. Another huge bummer compared to a standard old style lathe.

- The factory does have all the manual sets for each machine, all filed by the factory's allocated machine number. They are pretty good quality too, not Japlish. But... on examination and asking people who maintained them, there are not actually any circuit diagrams available for the electronics. Just cabinet wiring diagrams. And if something electronic blows, it has to be sent back to the Okuma factory for repair, or replaced with new. Costs are horrendous.

This is the kind of thing that I can deal with by reverse engineering (and then publishing derived schematics.) But it would be a huge sidetrack project, and I don't want to do it. - For transport, all CNC lathes have to have a fixture that secures the turret in place to prevent drift and damage under vibration. The factory management didn't imagine the place would go broke and the machines would be sold off, so when machines arrived they threw away those fixtures.

- Because the machines were spec'd and installed to one job each, there seems to be no significant stock of assorted tooling (cutters, etc) for them. At least if there was among the rows of pallets of sundries, I could not find them. Neither could auction staff when asked. I did find a few of the tool holder pieces (simple bit of steel with a round hole through the middle.) When I enquired later what those cost new, I was told $400. <faints>

- Not one of them has the tailstock & center option. I knew this from the auction photos, and had been informed by Okuma that this absolutely can not be retrofitted.

- A truly terrible trap for the unwary. I'd assumed that like any sensibly engineered software, the firmware in these would contain code to deal with all possible options on the machine. If something wasn't fitted, just ignore that.

But no... At the factory I'd enquired about what happens if a machine fitted with a gantry loader has the loader removed. Several people mentioned this wasn't advisable, and would involve 'messing around with the configuration' to get it to run.

Well, I thought that meant it was possible. Perhaps even fun. Back in Sydney I was informed by Okuma that every machine has its own code build, unique to that machine. If any attachements configuration is changed, Okuma must build a new code image and send to the customer. It comes on a stack of 3.5" floppies, for loading into the machine's flash memory.

I was told a customer recently had that exact situation — wanting to remove a gantry loader and use the machine by itself. The code from Okuma cost $7.5K.

Note that one of those nice machines in the big photo above (Lot 150) is listed for sale without the gantry. That will go with the other one. So someone may be in for a shock. - These LB250T machines all have a $2200 'removal fee', which includes making new transport fixtures, among other things. So the total cost of purchase is the bid + $2200 + auction fees + buyer transport costs. And if the machine has a gantry to be removed, or any other changes required, add up to $10K just for new software and whatever. Plus if there are any faults to be repaired, bend over and grease up.

Total cost of ownership of these things (in the typical industrial manner) is really out of my range.

Ownership in the self-sufficient Hacktivist sense — possible, but does carry a risk of total failure.

Towards the end of the day I'd pretty much concluded this was a stupid idea, and these machines would barely if at all be able to do my immediate machining need. Which left only the boy's toy appeal, and in general something to learn CNC machining techniques on. They use G-code files, same as 3D printers and PCB layout manufacturing. There was also the attraction of taking a machine with very corporate-controlled software, and doing some liberation hacking, just on principle. But did I want to lay out several thousand dollars for these kind of non-essential objectives?

I was mulling this over, wandering around in sightseeing and random chat mode, when time came to close the place down and the staff rounded up stragglers like me, and kicked us out (nicely.)

I'd taken nearly 100 photos. There's no point showing more than a few representative ones.

|

|

|

|

1. One with the tool position calibration arm folded out for use.

2. A tool turret.

3-4 and all the next row, general views. Imagine their electricity bill just for lighting.

|

|

|

|

|

|

|

|

1. Lot 152, the LB250T that is missing the tool calibration arm, has a completely useless spindle non-chuck, almost no tooling fitted on the turret, and is fitted with a gantry loader (see note re software cost above.)

2. Lot 153, which looks terribly worn and dirty. But actually apart from the paint it seems in good condition, has useful tooling, and no bloody gantry loader. I was thinking if I was going to bid on one, it would be this. Take the panels off, clean and respray them, it would look OK. Maybe because it looks so bad, the bidding would stay low? I wish.

3 & 4. Lot 605, a funny little free-standing cubicle, containing some customised automated machine to assemble something. At the time I didn't give it much attention.

I still hadn't seen everything, hadn't decided whether I wanted to try buying one of the CNC lathes, or if not were there any small items in the metrology lab I was interested in. So I intended to come back the next day too. I was coming down with a slight cold, hadn't had any lunch, and it was going on 4:30pm. I drove practically just across the road and had something to eat in a service station cafe.

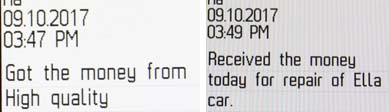

Check phone — good news, we've received the repair payment from the company whose truck dented the back of this car. They were very professional and pleasant to deal with, unlike someone else. Why did she send two SMSs?

Check phone — good news, we've received the repair payment from the company whose truck dented the back of this car. They were very professional and pleasant to deal with, unlike someone else. Why did she send two SMSs?

Called her, she's too busy to talk, it remains a mystery.

I'd handled getting the repair quote and contact with the truck company. Nice to know it worked out.

Today the weather is beautiful; clear-sky, cool. I want to camp at that 'Tin Mines' site, so head back to the park. Now it's dried out the Tin Mines Trail turns out to be OK for this car, so long as I drive slowly to avoid tyre punctures on the many sharp rocks used for surfacing. As I come out of the pine plantation a little way yet to North's Lookout, the road quality declines suddenly since there is no more rock surfacing, and it has eroded somewhat. But it still seems OK. Just avoid putting wheels in the waterholes made by 4WD-heads playing mud-splash in large vehicles.

Then, probably about 1 KM short of Norths Lookout, this:

|

|

|

Not the little ditch, that's fine. It's the exposed bouldery bit further up. That would be totally no problem for my Subaru, and walking over the rocks I could see this would almost certainly be OK for the little Mazda too, if I'm careful where the wheels go. But 'almost certainly' is not good enough. Once I start up it, I can't reverse out because there's no way to see where the wheels are going. If I put a wheel in a hole and floor-pan the car, I have zero recovery gear with me. Also don't want to put scrapes in this car. Drat.

Well, if I come down here again I hope it will be in the Subaru. Disappointed, I turn around and go back. There are plenty of potential camp sites along the route, but none appeal. 3rd pic was a nice view on the return drive.

When I get back to the junction with Tunnel road it's nearly dusk. Do I want to stay at that burned-forest site down the road again? No, not really. Do I actually need to go back to the auction site tomorrow? No, nothing important left to do there. OK, so home then. Unfortunately it's now after 6pm, so I'll be driving till between midnight and 1am. Oh well.

On the way back, with about 1.5 hours to go, I decided I'd better have a roadside nap. Which became a two hour stop. So I didn't get home till around 3:30am.

On the way back, with about 1.5 hours to go, I decided I'd better have a roadside nap. Which became a two hour stop. So I didn't get home till around 3:30am.

At 9pm there'd been a mysterious SMS. I'm used to this, it's pointless getting concerned by them. Some fixation of the moment... it doesn't mean anything, best not to reply.

As you'd expect, Tuesday was mostly a wipeout. Slept late, went to my mum's in the afternoon to do her chores and weekly shopping, didn't get home till late.

Incidentally, Sydney didn't get any of that rain at all. Still bone dry. Unwatered grass is dead, some smaller and less deeply rooted trees are starting to expire too.

20171011 Wednesday, a win for $1

Wednesday morning early my daughter and I dropped off the small car at smash repair shop. Wednesday and Thursday were the online auction bidding. I'd noticed that no one had bid on that big UPS and it was sitting at $1. That was surprising. With not long to go I bid $11. The auction ended at 2pm with still no other bids, so it was mine for $1. Cool, and very unexpected. However it does mean I definitely have to go back to Albury to collect it, and that means my Subaru has to be back on the road, and my trailer re-registered, in time. Awkward.Since I have to go back, was there anything else very cheap I could pick up? The Metrology lab sale was running till 5pm, so I looked through that. Crazy bidding was going on, but I found a couple of things that might stay low, that interested me. One was a dryer, that I have one of but missing a couple of parts. The one on offer was complete, so I bid low on that. The other was a rather crappy looking 'test tube agitator'. On my recent trip to Melbourne for some medical chemical analysis work by a chemist friend, I'd seen a similar one in use and thought it was neat. So bid $1. Won that, but not the dryer. Ha.

The early bidding on the Okuma LB250T CNC lathes was as expected slow. Those Lot numbers ended on the 12th (Thursday) at midday, and all the serious bidders will enter in the last hour or so. People playing 'few dollars leapfrog' now on Wednesday are silly and just wasting their time. But there are always fools...

Speaking of fools, I had decided that yes, I would like to have one just to play with, software hack, and maybe actually do some useful machining with now and then. But didn't want to pay much for effectively a toy, and considering I still have to find and buy an old lathe that could do what I actually needed. Would they go over my limit? The 'big UPS for $1' had made me a bit more hopeful for low prices. Also what would the bidding pattern be?

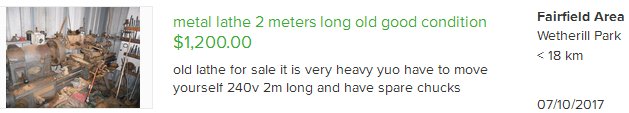

Which reminded me, it's been a while since I checked gumtree for old lathes. Around 9pm I clicked on my saved gumtree search link, scroll through the listings of lathes on offer. Hmm... nope, nope... Wait, what the hell?

Oh gosh. It's my old mate Lying Lunatic Nick again. Same lathe, same photo. And... all his same things are listed again. He has not sold even one thing from that shed yet.

Oh gosh. It's my old mate Lying Lunatic Nick again. Same lathe, same photo. And... all his same things are listed again. He has not sold even one thing from that shed yet.

Ha ha ha ha... <inhales> ha ha ha ha ha ha!

Wow. So apparently the poor fellow really does have some kind of mental disorder. What was all that business with taking the listings down one by one, presumably pretending they sold? Then putting them all back now? All at the same prices except the big lathe, which he's reduced from $1300 to $1200. Even the item wordings are the same, since several of them still have his first asking price in there, though the heading price is now lower. They seem to still have original listing dates too, like 02/09/2017.

Going on past performance he won't respond to me, no matter what I say. I'll consider whether I should organize someone to pretend to be a buyer but acting as my proxy, and offer him $1000. But the payment and pickup process would be complicated, by having to safeguard against repeat lunacy. Do I really want to get involved with that nutcase again? I'll think about it after the Albury auction is over. Nick's lathe is not going anywhere soon, I think.

20171012 Thursday, CNC lathe bidding

The CNC lathes online auction ends at midday. Just in case I won I'd made sure my bank account held enough to cover the required immediate auto-payment of $1000 deposit. My other reason for bidding on small items the day before was to familiarise with the bid proceedure and check everything worked. It did. But I'd found that bidding on the Pickles site wasn't a one-click action. There are a few things to work through, and it takes a little while. Another reason ebay-style snipe bidding won't work is that any last minute bid extends the bidding deadline on that item by 10 minutes.I wanted to keep track of five items, so opened five browser windows, one each. And to keep a record of bidding on each, a text editor with five tabs open. Into which I could paste bid events. The Pickles pages only show the last few bids. And once the Lot's auction is over, all information on it including the final bid becomes invisible.

In summary, four of the five went way over my limit long before close. Those included Lot 153, the 'bad paint day' one, that I'd hoped would lag. So I didn't bid on it at all. Its final bid was $2800, the lowest of all the Spaceturns, despite that functionally it was probably the most useful. Appearance matters!

Lot 152, the one with the calibration arm missing was starting slowly. One hour before close it was still just $13 and I wondered if it might not take off, so I joined the bidding. But was quickly left behind. My max bid was $1350; the final bid was $3,050.

|

Lot 149 E.H. Winthrop WA 12/10/2017 12:12PM $3,550 R.B. Point Cook VIC 12/10/2017 12:12PM $3,500 E.H. Winthrop WA 12/10/2017 12:11PM $3,450 S.T. dandenong south VIC 12/10/2017 12:11PM $3,400 E.H. Winthrop WA 12/10/2017 12:05PM $3,350 S.T. dandenong south VIC 12/10/2017 12:05PM $3,300 E.H. Winthrop WA 12/10/2017 11:59AM $3,250 S.T. dandenong south VIC 12/10/2017 11:59AM $3,200 E.H. Winthrop WA 12/10/2017 10:19AM $3,150 S.T. dandenong south VIC 12/10/2017 10:19AM $3,100 E.H. Winthrop WA 12/10/2017 06:31AM $3,050 R.B. Point Cook VIC 12/10/2017 06:31AM $3,000 E.H. Winthrop WA 12/10/2017 06:31AM $2,550 E.H. Winthrop WA 12/10/2017 10:19AM $3,150 S.T. dandenong south VIC 12/10/2017 10:19AM $3,100 E.H. Winthrop WA 12/10/2017 06:31AM $3,050 R.B. Point Cook VIC 12/10/2017 06:31AM $3,000 E.H. Winthrop WA 12/10/2017 06:31AM $2,550 R.B. Point Cook VIC 12/10/2017 06:31AM $2,500 E.H. Winthrop WA 12/10/2017 06:30AM $2,150

Lot 150

Lot 151 |

Lot 152 S.T. dandenong south VIC 12/10/2017 12:11PM $3,050 P.M. dandenong south VIC 12/10/2017 12:09PM $3,000 S.T. dandenong south VIC 12/10/2017 12:09PM $3,000 P.M. dandenong south VIC 12/10/2017 12:04PM $2,950 S.T. dandenong south VIC 12/10/2017 12:04PM $2,900 P.M. dandenong south VIC 12/10/2017 11:56AM $2,850 S.T. dandenong south VIC 12/10/2017 11:56AM $2,800 P.M. dandenong south VIC 12/10/2017 11:54AM $2,250 S.T. dandenong south VIC 12/10/2017 11:54AM $2,200 P.M. dandenong south VIC 12/10/2017 11:50AM $1,550 S.Y. Woolloongabba QLD 12/10/2017 11:50AM $1,400 G.D. East Hills NSW 12/10/2017 11:50AM $1,350 S.Y. Woolloongabba QLD 12/10/2017 11:49AM $1,300 S.Y. Woolloongabba QLD 12/10/2017 11:49AM $1,300 P.M. dandenong south VIC 12/10/2017 11:48AM $1,250 G.D. East Hills NSW 12/10/2017 11:48AM $1,200 P.M. dandenong south VIC 12/10/2017 11:47AM $1,150 G.D. East Hills NSW 12/10/2017 11:47AM $1,100 P.M. dandenong south VIC 12/10/2017 11:46AM $1,050 G.D. East Hills NSW 12/10/2017 11:46AM $1,000 P.M. dandenong south VIC 12/10/2017 11:45AM $860 P.M. dandenong south VIC 12/10/2017 11:03AM $760 S.Y. Woolloongabba QLD 12/10/2017 11:03AM $750 P.M. dandenong south VIC 12/10/2017 11:03AM $510 S.Y. Woolloongabba QLD 12/10/2017 11:03AM $500 P.M. dandenong south VIC 12/10/2017 10:59AM $13 V.V. Matraville NSW 12/10/2017 10:21AM $5 S.T. dandenong south VIC 12/10/2017 10:21AM $4 V.V. Matraville NSW 12/10/2017 07:37AM $3 R.B. Point Cook VIC 11/10/2017 06:06PM $2 E.H. Winthrop WA 11/10/2017 11:48AM $1

Lot 153 |

Oh well. I'd been conflicted about whether I should even try to win one of those potential albatrosses, so failing to win one was kind of a relief. Also it means I have more cash left in the fund for 'buy an old lathe, that I actually need.'

On the other hand, disappointing — no boy's toy for me. But wait, I do have to go down there for the UPS, and there's another auction ending around 4pm. I was going to watch that anyway, to see what ridiculous price an old Dean Smith & Grace lathe sold for. An old machinist I'd met there on Monday had commented he'd pay no more than $500 for it. I thought maybe a bit more, but I expected bidding to go wildly over that, so I'd stay out of it. Not to mention that while shipping a heavy CNC lathe from Albury to Sydney may have made some sense, shipping a heavy old lathe that distance absolutely does not make sense.

In the meantime, why don't I skim through the listing to see if there's anything I might win for entertainment value, that would also fit in the trailer? This turned up: Lot 605 Assembly machine cubicle. Which I'd seen when I was there and thought was an amusing Heath-Robinson contraption. I'd taken one pic — #2 below.

|

|

|

Now I give the photos some more attention. Huh. I spy with my little eye, something beginning with T-slot. The aluminium framework — it's expensive and very useful stuff, and I will need to buy some anyway for an intended project. Here there's an abundance of it, with plenty of slot nuts and stainless button-head screws. Plus oodles of nice pneumatic controls and actuators, and that control cabinet will be full of goodies too. Also those two huge pneumatic cylinders —, hey there's enough there to make a neat general purpose press. And the windows; I bet that isn't perspex. Lexan maybe? I could get that thing converted to a smallish pile of juicy parts in less than a day, I think. There's a massive welded steel base frame; they can keep that for recycling with all the other scrap steel I expect they'll end up with.

Yet, when I looked it was still sitting at $54. No... it couldn't, could it? I decided I'd bid up to #130 (ha ha), and jumped in at 15 minutes to go. Sigh... straight into an incremental bidding war, with some guy who also could see value in it and wasn't going to give up. (Or who works for Pickles. You can never know.)

|

Lot 605 N.W. Footscray VIC 12/10/2017 04:19PM $420 G.D. East Hills NSW 12/10/2017 04:19PM $410 N.W. Footscray VIC 12/10/2017 04:19PM $410 G.D. East Hills NSW 12/10/2017 04:14PM $400 N.W. Footscray VIC 12/10/2017 04:14PM $390 G.D. East Hills NSW 12/10/2017 04:14PM $380 N.W. Footscray VIC 12/10/2017 04:14PM $380 G.D. East Hills NSW 12/10/2017 04:09PM $370 N.W. Footscray VIC 12/10/2017 04:09PM $370 G.D. East Hills NSW 12/10/2017 04:03PM $360 N.W. Footscray VIC 12/10/2017 04:03PM $360 G.D. East Hills NSW 12/10/2017 03:57PM $350 N.W. Footscray VIC 12/10/2017 03:56PM $340 G.D. East Hills NSW 12/10/2017 03:53PM $310 N.W. Footscray VIC 12/10/2017 03:53PM $300 G.D. East Hills NSW 12/10/2017 03:44PM $130 N.W. Footscray VIC 12/10/2017 03:37PM $110 S.S. NORTH ALBURY NSW 12/10/2017 01:11PM $54 N.W. Footscray VIC 12/10/2017 01:11PM $53 S.S. NORTH ALBURY NSW 11/10/2017 10:54PM $52 P.B. baranduda VIC 11/10/2017 10:53PM $5 S.S. NORTH ALBURY NSW 11/10/2017 10:53PM $4 P.B. baranduda VIC 11/10/2017 10:53PM $3 S.S. NORTH ALBURY NSW 11/10/2017 10:53PM $2 |

Bah. That took all the pleasure out of it and wasted 20 minutes past the auction supposed end time, by repeatedly extending the run-time. At $410 I decided this was getting ridiculous, and had broken the fun per buck ratio for me. I quit.

There was still some entertainment in store though. Not long after that I checked email. Assorted bumpf from Pickles about being outbid (several times, and thanks for reminding me.)

Also two Dear John letters:

CNC Lathe, Single Spindle, Okuma, Space Turn LB250T, S/N: 1212.0153, Okuma OSP-U10L controller, [snip]

This item may be listed again in the near future. (This was Lot 152, the CNC lathe I bid on.)

Assembly Machine, 40882, CPE, Custom, Siemens Simatic Panel touch screen, 3 station, [snip]

This item may be listed again in the near future. (This was Lot 605, the cubicle above.)

But this raises the question, what were the reserve prices? What proportion of items 'passed in'? I have a hunch it was large. The existence of reserves didn't seem to be mentioned in the advertising for the auction. But I suppose I should have known.

Anyway, all up that auction cost me $2.16, according to my bank statement. For the big UPS that's excellent, even adding in petrol for the two trips.

Oh, and that old lathe?

|

Lot 350 S.T. dandenong south VIC 12/10/2017 04:01PM $2,400 J.M. Wodonga VIC 12/10/2017 04:01PM $2,350 S.T. dandenong south VIC 12/10/2017 04:01PM $2,300 J.M. Wodonga VIC 12/10/2017 04:00PM $2,250 S.T. dandenong south VIC 12/10/2017 04:00PM $2,200 S.T. dandenong south VIC 12/10/2017 03:30PM $1,400 D.B. Numurkah VIC 12/10/2017 03:29PM $1,350 S.T. dandenong south VIC 12/10/2017 12:35PM $1,200 D.B. Numurkah VIC 12/10/2017 10:36AM $900 S.T. dandenong south VIC 11/10/2017 11:01PM $690 S.S. NORTH ALBURY NSW 11/10/2017 11:01PM $680 S.T. dandenong south VIC 11/10/2017 10:48AM $670 J.M. Wodonga VIC 11/10/2017 10:27AM $660 |

Note to self: If participating in any future Pickles auctions, on any item of interest make one bid while it's under $10. That way you at least get to be informed if it is passed in. And therefore may be available again in future.

20171014 Saturday. The MACSON

Friday should have been 'recovery day', but actually my cold had been getting worse, and by then was really bad. Also a friend came to visit for all the afternoon. Friday night I was very sick, an awful night. By Saturday I was feeling a bit better and started to get back into the queue of chores.

One good thing that had come from the day of wandering around in the factory, was meeting people who knew something about second hand lathes. I'd been given several names of Sydney and Melbourne people who traded in them, and so talking to them was high on my todo list. I'd start that on Monday.

One good thing that had come from the day of wandering around in the factory, was meeting people who knew something about second hand lathes. I'd been given several names of Sydney and Melbourne people who traded in them, and so talking to them was high on my todo list. I'd start that on Monday.

Meanwhile it's Saturday. There's still the matter of whether Mister Nick might somehow be persuaded to actually sell his rusty, missing-bed-gap-piece lathe for a reasonable price. Around 3pm I had a look at Gumtree again.

Yep, there's Nick's woeful mistreated old thing...

Right below his entry there is a much better looking big old lathe, for $900.

|

It'a a MACSON Model 17-17.

36" between centers, 14" swing.

I contact the seller. It has a faceplate that is big enough for my job, it's not very far away from me, and there's a guy coming down from the Nth Coast to see it tomorrow. I arrange to go over immediately to inspect it.