An amazing thing happened today!

For months I've been buried under life problems and assorted time demands that could not be put aside. For instance the Dunphy Kowmung centenary walk, making the railings for my mum, and most recently and annoyingly the Bankstown rezoning disaster that chewed up over a month and threatens to eat entire years of my future time. Just to name a few, of many.

Now with some hope dawning for actually getting a block of time to work on my own stuff, I'd decided the next thing I should do is the long-postponed fourth component of my vacuum experiments system. The rack to hold vacuum pumps, gas control and the 200KV supply.

The plan was to fabricate another of the wheeled bases like I've done three of so far, then cut down the height of a 2nd ex-telecoms rack (bought for $50 early this year, and sitting in the storage shed since) to mount on the roller base. Then fit the HV supply on top of that, plus construct an open-mesh Faraday cage around the HV supply. (So as not to die when I use it.)

Quite a bit of work, not even counting whatever it will take to mount the pumps and other stuff in the rack. They're not exactly 19-inch rackmount format, but making supports to bolt them into a standard rack sounds a lot more flexible than making a fully custom structure. I have no illusions about my ability to plan for unknowns, and the first layout is certain to need rearrangements as the project develops.

Still, it was time to get into it. I fetched down the rectangular steel section stock I'd bought a while ago for this project.

Hopefully, I'll be able to start construction this weekend.

On Wednesday a friend had contacted me, said he'd drop round in the evening. Didn't say what for, so I assumed just a social visit. Then he didn't show up. Had sent me an SMS explaining, but it didn't arrive.

Today (Friday) he arranged to come tonight, around 6pm. This time he showed up, with another friend. Saying hello at the door he explained the visit was to give me something — but he was still keeping it a surprise. We go out to their car. The gift is another of those HP 19" equipment racks, same as my 'black rack'. This one has only superficial damage to panels; the frame is not bent so doesn't need any straightening work. My friend works at an IT equipment supplier, and they now and then toss out damaged or obsolete stock. Like this rack.

I'm astonished! It's exactly the right size for what I need. Don't need to make the roller base after all, I can just use this one as-is. It even has screw-down secure mounts, though they are not as easy to get to as on the roller bases I made. The two side panels are usable too, though one needs a little repair work. I hadn't even spoken with my friend for a few weeks, and he had no idea what I was up to, let alone that I was about to start this project.

How's that for cool? I was just thinking about a need, and the solution shows up at my door within a few days. The day before I was due to start putting in considerable effort, the need for which was eliminated by this stroke of luck.

Count this as another of the amazing coincidental boosts that seem to keep happening with this particular project.

So this evening I tidied up the pile of stuff that was sitting where this rack will go, and started mounting some of the gear. Most of the pile was things waiting for this rack.

It actually took a while to get the top (blank front panel) unit mounted. It's the grunt box of the 200KV supply, and as it's rather heavy I wanted it supported by more than the front panel screws. Both so it doesn't bend under its own weight, and also since trying to manually support it in position while putting in the front screws is painfull and risks dropping the unit.

But I didn't want to use full depth rails, since they would obstruct too much free space at the rack rear. What to do?

At first I thought a standard rackmount shelf would be perfect, till I realised the shelf's side panels block the cooling air vents on the sides of the power supply box. Nope, can't do that. Also, the shelf design assumes it will be mounted on the front vertical struts of the rack — but in this case the power supply needs that attachment point.

This entire rack project is sure to be like this - continual improvising and hacking. Here with the very first thing to go into the rack I had to do something unusual.

This entire rack project is sure to be like this - continual improvising and hacking. Here with the very first thing to go into the rack I had to do something unusual.

That standard shelf is mounted upside down and set back from the front by attaching to a couple of short L-sections bolted to the rack's side frames. (Click pic for larger size.) This also gave enough height adjustability to allow the shelf to support the unit exactly where it lines up with the front mounting holes. The shelf front edge fold (which was 'down' but became 'up' in this configuration) had to be cut off, but that only took a few moments with a thin cutting disk in an angle grinder then a bit of quick-dry spray paint.

Later in this piece I'll do a review of the Spellman 200KV power supply internals and operation; it's an interesting piece of gear.

The Spellman supply and some other crucial items including the main vacuum chamber were gifts from someone to whom I'd described the objectives of this project. He was a retired physicist, who just happened to be involved at that time in decomissioning a particle accellerator system, and had been in partnership with someone else who'd built a large stainless steel vacuum chamber for an industrial process but no longer needed it. He liked the concept, and as encouragement gave me quite a lot of gear from the old accellerator, plus the chamber. That wasn't the first stroke of luck in this journey, but it certainly helped hugely.

Right away this rack received an official 'I fits!' seal of approval, from Tiny. I hope everything else fits too. Since there'll be a lot of improvising and revising in the development of this rack, there's no point trying to begin with anything more than a vague outline of how I want it to end up. So I really don't know if it will all fit. Fingers crossed, and JUST DO IT!

20141214 Sunday

|

|

|

|

|

Now I have the 200KV supply installed, and a plywood base board made to fit in the bottom of the rack. The plywood was free scrap.

The sheet metal top cover of the rack is too thin to tap threads for mounting the HV multiplier stack, and I didn't want to have to mess around blind-feeling nuts into place every time I assemble this. So I soldered steel nuts to the bottom of the sheet metal.

The original plan was to mount the biggest vacuum pump (and maybe the smaller one too) directly on the base board. But thinking about it, and knowing how prone vacuum pumping systems are to oil spills, I decided I wanted an oil catch tray under the pumps. Therefore the pumps needed to be up off the base board, so a spill tray can be slid underneath.

It's so great that already the 'next thing' is to fit the Busch high capacity vacuum pump. This rack saved SO MUCH WORK!

The Busch pump is a beast. It weighs 57 Kg and the tag claims "63 cu meter/Hr". Also "Torr 99.7%" which is an odd mangling of units that I presume means the ultimate percentage of atmospheric pressure. This will be for getting the big vacuum chamber pumped down fast. Then a smaller rotary backing pump will take over.

The Busch pump is a beast. It weighs 57 Kg and the tag claims "63 cu meter/Hr". Also "Torr 99.7%" which is an odd mangling of units that I presume means the ultimate percentage of atmospheric pressure. This will be for getting the big vacuum chamber pumped down fast. Then a smaller rotary backing pump will take over.

There's another serendipitous story to this pump.

Back in Jan 2010, on a Friday evening I was in the inner city with some friends. The destination was a demolition site, to explore the remnants of a very old industrial building for fun and photographs. On the way there, walking along a back lane I came upon some junk apparently street-tossed on the kerb — probably from a small industrial business opposite.

There am I, in general trying on a shoestring to set up workshop spaces to do two projects - one making cast metal sculptures, and the other (in my main workshop) some speculative physics involving vacuum chambers and such.

What do I find tossed out on the kerb in that lane?

- A small self-contained induction furnace. Used to melt metal, using a high power AC magnetic field. Typically used for precious metals, but works with any metal. It's a beautiful machine, intact, in good physical condition. (Later: and actually works!) I always wanted an induction furnace, but they are hellish expensive.

- A big, high pumping rate vacuum pump, possibly a roots or scroll type, portable enough and complete with motor, oil tank, backflow stop valve, inlet filter, etc.

At the time, in the dark in that lane, I couldn't tell what either of the two objects was. Just 'technical orphans' of some kind. One of my friends in the group and I took a few minutes to go get my car, toss them in the back, repark car, then catch up with the others in the expedition.

Later at home I cleaned and inspected them, before attempting to power either up. So far so good, though not expecting the induction furnace to be functional. Lots of electronics. But I was hoping it's at least fixable. They were thrown out by the business there; later identified as a small metal casting works, that aparently does precious metals work. Best case is they were just superfluous due to upgrading. So I thought they might both actually work.

It turned out they both worked perfectly. The pump had a couple of wires loose in the three-phase plug, so may have operated intermittently. It also had a stripped thread in the cast-aluminium oil-backflow-stop valve, that I fixed. At that time I didn't have a TIG welder but a friend did. He TIG-welded the hole closed, I drilled and re-tapped it.

The induction furnace is operational but missing a refractory liner tube and top-plate. Also needs the special ceramic-carbon-lined crucible, since it seems likely that is optimal for induction heating. About this, the story got even funnier. I thought I'd like to thank the factory owner for his street-toss, that was so useful to me. And also ask if he had a spare crucible or knew where I could buy one. The induction furnace is made in Italy, so there's a slight problem with spare parts.

A couple of days later I went there during business hours. There were employees doing stuff outside, and I asked to speak to the boss. After a while he came out (I knew it's a precious metals business, so wasn't expecting to be invited in.) I introduced myself, then by way of opening asked if he was aware of the vacuum pump and induction furnace thrown out the other day.

Ha ha... at which point he went all cagey and denied knowing anything about them. It was obvious he figured I was someone from the council, trying to get him into trouble for street dumping. Hmm... I don't like people who lie, and I hadn't got a good impression about this guy from the start. So I didn't just come out and say why I was glad to have them, and thank him for them. If he was going to deny everything, no thank-you for him! I just walked away, a little sad about the failed opportunity to obtain a spare/used crucible. But my gut feeling said this guy wasn't the kind to give anyone anything.

And then.... just after he'd denied any knowledge at all about any Busch vacuum pumps, as I was walking away but still in front of their building, a shiny new van sporting Busch Vacuum Systems Customer Service logos pulled up at the business's main entrance. The van driver went inside. Ha ha ha... because this establishment knows nothing about any Busch vacuum pumps, of course! The timing was hilarious.

Incidentally, this is exactly the kind of pump used for vacuum casting metals in highly detailed molds.

The combined serendipity factor here was off the scale.

- The induction furnace - may be a huge help, in allowing me to produce small bronze sculptures much earlier than I'd have been able to if I'd had to build my own oil-fired furnace before I could do anything. As soon as I have sculptures for sale, I'll be elligible for the gov NEIS support scheme - which will make a great difference to the viability of the whole 'becoming a sculptor' plan.

- The vacuum pump is exactly what I need for the large experimental vacuum chamber — a very high rate roughing pump. It also is actually intended for vacuum investment casting of detailed small artworks, so includes a dust filter on its input port, and an efficient oil mist filter on the output.

- My happening by in the short interval (a day or two?) between when the factory street-dumped them, and when they'd have been removed. The rolley bins were out that evening, so maybe the units would have been gone the next day.

Mounting that big pump was more awkward than a Silly Walk. It needs to be on vibration isolating rubber mounts, but the arrangement of the mount points on the pump is odd. There are three, and they are not quite on a rectangular grid aligned to the pump body axis, nor all at the same height. To make things more difficult the pump contains 2 litres of oil, which can leak out if the pump is placed on its side or upside down. Did I mention it weighs 57 Kg and has no convenient lift points? It's a pain to move around.

So the first thing needed was a full scale paper puppet, with the mounting points transfer-marked from the pump.

So the first thing needed was a full scale paper puppet, with the mounting points transfer-marked from the pump.

Thankfully the mount point threads are a sensible metric 8mm. I machined three M8 bolts into these 'marker pins'. Actually should have only made two, since one of the mount points was higher than the others and required a longer pin. I ended up using a plain M8 threaded rod with a pointy end, to get the needed extra height.

With the pins screwed into the mount points under the pump, I put a sheet of paper on a soft wooden board, then lifted the pump over the board and lowered it gently till resting on all three pins. Its own weight pressed the pin points into the paper. The rough outline of the pump was then drawn onto the paper with a felt pen run around the edges of the pump. Lifting the pump off carefully (to not make multiple pin impressions), then cutting away some excess paper resulted in the paper puppet. Infinitely easier to move around than the pump! It also allows the mounting frame parts to be designed and made using the puppet as a layout guide.

|

|

|

|

|

That's where the pump will sit in the rack, but a couple of inches up off the base to leave room for a spill tray.

The general rule when commencing a design in which multiple elements are unknown at first, is to minimize potential interferences. Try to make each element encroach on remaining free space as little as possible.

For the pump mount bracket that means that although I've decided to raise it up off the base board, still every mm of height above the pump is precious. So rather than mount the rubber vibration isolators directly on the bracket struts, I offset the struts from the mount points, allowing the rubber pads to partly occupy the same height as the struts. The pads chosen are 30mm diam too, so it doesn't hurt to have a nice big flat tab for them to sit on.

|

|

|

|

|

Once the frame has the first two tabs mounted, which are at the same height, the frame itself can be used to figure out the height offset needed for the third tab. With the frame level, the pump is sat on it using wooden dummies in place of the rubber isolators. Wedging it up to be level gives the plane where the third frame tab has to be — as in the 4th pic. Then the same shims are used to position the tab for welding.

|

|

|

|

|

As usual with welding to the side of a straight section, the result is a non-straight section due to cooling shrinkage of the weld metal. Nothing a bit of reheating and brute force with a big jack won't fix. Fine adjustment with a mallet.

I had belatedly discovered that the 'under motor' mount point threaded hole was several degrees off vertical. Since that meant the rubber isolation pad would be permanently stressed, I'd unbolted that mount point base and fixed the tilt. (Yay, angle grinder!) However that meant my paper puppet pin impression was now going to be a bit off. To get the hole in the mounting frame exactly right, I redid the pin impressioning. This time directly onto the mounting frame with the other two holes bolted to their pump mount points. For this it was necessary to lift the pump up with a hoist.

|

|

|

|

|

Done and painted! This enamel paint takes days to dry hard enough to resist scrapes, and I often end up scratching such things in my hurry to use them. This time there's no hurry since it will take weeks for the rubber vibration isolators to arrive. I'd tried to buy them locally with little luck till I found stock at Blackwoods. But ha ha ha! They wanted $24.14 EACH! Compared to $11.48 for five, plus free shipping, from China via ebay. Sigh.

Still, to proceed with the next pump I'll need to mount this frame and pump in the rack with dummy spacers, to be sure of clearances.

20141225 Christmas day — Reverse Serendipity?

This year we had our Christmas family dinner on the 24th, since my son had to leave for work (in Nth QLD) early on the 25th. So on the 25th after putting the second coat of paint on the pump frame I had a relaxed day just doing a few minor odds and ends. And feeling sick, with the flu I caught recently. One time-passer was checking out and parts-mining some old PCs I'd salvaged, to get them off the floor here. Mostly I'd grabbed them from a street-toss because I need some more of the thin sheet steel typical of PC cases, to finish off another project (which is being written up as it goes.) However it's often very amusing to find that a PC owner made no attempt whatsoever to erase their hard drive before discarding it on the kerb, so you get a window into someone's life over recent years. And frankly, I have no idea how the NSA can stand their work, since if old PC hard drives are any indication many people's lives are incredibly dull and boring. Or maybe that's just a selection effect, due to only seeing HDs from people who didn't know how to type "Format C:" (Yes, I know it takes more than that to be effective, but that's not the point.) If you need something to put you to sleep, I can send you this guy's resume. (I'm joking, in fact it will all be erased and only a blank drive will remain. I'm not that much of an arsehole.)There's a purpose to this rambling, and it starts with the screen background image on that discarded PC.

Filename 'nightelfboxart'. Is that from some game? I don't know, and I can't google it at the moment, because....

Filename 'nightelfboxart'. Is that from some game? I don't know, and I can't google it at the moment, because....

This PC was sitting there with that desktop image, while I did other stuff during the afternoon. Around 5pm a small thunderstorm started. Just a few booms, not even very big ones. A small amount of rain. Really quite a pleasant chibi-storm.

About 5:30pm I was at my desk with that pic on a monitor to my left, and I was just thinking "that electric-eyed photoshop freak is starting to creep me out, I think I'll erase her" when 'snapBOOOOOOoooooommm.'

A very close lightning strike. Wow, cool. I was next to a window but hadn't seen any flash. No power glitch, PCs are all still on. I'd also just been posting to eevblog, asking if anyone had a turbomolecular vacuum pump for cheap. Next thing I did after the lightning strike was something else online, annnnddd... no response. No net. Oh good.

I started investigating. Oh oh... in the workshop wiring closet there are no active port lights lit on the 16-port switch. Should be at least three now. Digging out an old 10/100 switch I use it as a tester - plug things into it, the port indicator lights show if they establish communication.

Here's what died:

- On the 16 port 10/100 switch, one port of 16 is dead - #2 port. (I think this was the one to my PC.)

- The ethernet port on my main PC. Well that sucks.

- Ethernet port on the NAS. (Oh GREAT! Hope the drive is OK. It still spins up.)

- LAN port #1 on the Optus cable modem. Other 3 are OK. (#1 was plugged through to the workshop building.)

- Upstream on cable modem is dead. Status LED dark.

- The Optus cable phone line.

- Telstra phone line.

- The TV antenna line amplifier (and the TV)

- The blackrack PC, and its net port. (Lucky. It was up, connected to the LAN and playing music from its HD at the time.)

- The cable modem console, which says 'cable connection - not connected'.

- The 'nightelf' PC wasn't connected to the LAN, so of course it's fine.

So, I guess no net till late Monday 29th Dec. Nearly four days without internet. It's an odd feeling.

I will never diss a lightning-eyed night elf again. Though I see on closer inspection her eyes are supposed to be diamonds. Glowing diamond eyes, which is no more unrealistic than lightning-eyes, I guess.

Sigh. It was quite a small, brief storm, only a few lightning thunders. We've had far worse with no damage. Just that one happened to hit very very close. Oh well.

An interesting point. There was a very distinct sharp 'SNAP' sound, as of a small HV capacitor discharging. Followed at a barely perceptible interval by the much louder BOOOOooom of thunder. But although the delay was barely there, it WAS there. The distance was far enough for the main air-propagated clap of thunder from the lightning arc path to take maybe 100mSec to arrive.

So what was the 'SNAP' sound?

My guess is it was local (in my room) accoustic induction from the EMP wavefront. It may have caused actual small arcs between metal objects around me, as well as causing them to physically move due to eddy currents. In a symbolic sense, it was the sound of my main PC's ethernet port dying.

Bah. That whole 'glowing eyes' trope pisses me off immensely, for its fundamental stupidity. Any time I see a creature in a movie or anywhere imagined with glowing eyes, where it's not just a reflection of a light shone into those eyes (like with my cat Tiny above), I automatically assume the director/artist was a moron. Someone incapable of achieving the simplest, most obvious understandings of the natural world. Such as the concept that eyes are light receivers, not light sources. If they actually glowed, they wouldn't work as eyes. Glowing eyes are too ridiculous to be scary.

20141226 Friday

|

|

|

|

|

I'd been wondering how to lift the pump into place in the rack. Manually I can only lift it straight up while straddling it, so obviously some mechanical aid would be needed to get it into the rack. For a while I'd been mentally hung up on the idea of improvising some sort of fork-lift like thing. But finally a better way occured to me. Ah, so slow, this should have been obvious initially.

In my 20s I'd been to White Cliffs in far-west NSW, and was lucky to be invited to spend a day underground with one of the local opal miners. They use a very clever and simple trick to shift large amounts of rock spoil around in small tunnels. Get some lengths of old iron water pipe, and lay them in pairs about 50cm apart on the floor. At tunnel bends overlap the pipe ends next to each other, the spacing doesn't matter. The pipes get pressed partly into the loose rubble on the floor, so stay put. Get an old 40 gallon steel drum and cut the top out. Take a stick with an oily rag wrapped around the end, and run it along the pipe 'rails'. Rest the drum base on the rails, and push it along by hand. It's amazing how easily a drum full of rock slides along the greasy smooth pipes. The same drum gets hoisted up the shaft to the surface for rock tipping, so the whole process is quite efficient.

I didn't need to lift the pump into the rack, I could simply slide it on a couple of greasy steel bar stock pieces. Easy!

And I'm glad it's so easy, since as soon as it was in place I remembered that I should take the wooden base out and paint it. Oops. I'd forgotten about that over Christmas. Anyway, later. The pump is only temporarily mounted on isolation pads which I had, but which are too small and have the wrong thread. So it's just sitting there and does have to come out again.

There are two things next: Deciding which of the two smaller pumps (last pic) to build in, and making some kind of exhaust capture shroud for the Busch pump.

Since it's designed for metal casting mold evacuation, that pump simply vents the outlet to the room. It does a very good job of capturing and recyling oil mist (that entire green box next to the motor-pump axis is a multi-stage oil mist filter and noise muffler), but the assumption is it's only pumping standard air. For my use that will mostly be true too, but I want to be able to vent the evacuated gas to outside if necessary.

In pic 3 above, the green mesh of holes are the air outlets. This needs modification, to exhaust to a pipe fitting. This is why the entire pump is set back from the end of the rack — to leave space for that mod.

Spellman 200KV Power Supply

This beast was once part of an ion-implanter used for semiconductor manufacture in the USA. Then (presumably after being obsoleted) the implanter was brought to Australia as learning toy for physics students at a university. Eventually it was scrapped, and I was fortunate to be given some of the parts. Including this regulated HV power supply, which generates from 0 to 200KV at up to 1mA. So at peak output it's handling 200 Watts.

|

|

|

|

|

The main case contains two identical power oscillators; each with a mains transformer, rectifier and series pass regulator providing power to a self-resonating oscillator driving the primary of a high voltage air-cored transformer. All windings of the HV transformers use Litz wire, and the secondary is wound in multiple air-gapped disks to prevent arc-over and aid forced-air cooling. The two drive circuits run in sync, and the transformer secondary outputs are wired together to provide one HV AC drive which is passed to an external multi-stage diode-capacitor voltage multiplier ladder.

In that ladder HV stack, there is also a HV sense resistor back to ground. The current through this is used to regulate the output voltage, by varying the LV (40V max) DC supply to the dual ganged oscillators.

|

|

|

|

|

The power-handling sections of the unit are very simple; just a lot of grunty parts paralleled up. There's only one small control card, and it's very simple and low tech. The op-amps are 741 type. I'll include the schematics later, when I scan them.

Control and metering signals are brought to a rear connector, which allows the operator's control panel to be mounted some distance away. A very desirable thing when running voltages up to 200 KV.

|

|

|

The multiplier stack. Circuitry in which the breakdown strength of air, corona discharge from anything pointy, and equalisation of electric field strength gradients in free space all need special consideration.

The long straight tube things are HV diodes - well actually probably many diodes each, encapsulated in silicone potting compound. The gray blocks behind them are potted HV capacitors, two to a block. The round balls are 'non-pointy nuts' — literally nuts, used to attach wires to screw terminals but presenting a large smooth surface to the air to minimize corona discharge. Even the placement of interconnecting wires is carefully arranged to minimize field gradient local intensity.

The metal rings are electrically connected to intermediate stages in the stack, and serve to maintain an evenly divided field strength in the space around the stack.

In the last pic the continuous gray block at right is the output voltage sense resistor.

Of course, high voltage and low gas pressure are a dangerous combination, since the result of accellerating particles and then stopping them suddenly when they hit something, is X-rays, and at higher energy ranges, Gamma rays. This 200KV supply is seriously overkill for my purpose, and I don't expect to ever run it above about 10 to 30KV while the system is under vacuum. Also as a precaution I'll be running a gamma spectrometer next to the vacuum chamber, checking for unwanted ionizing radiation. (It detects X-rays too.) In other uses the higher voltages will be used for capacitor discharges at or near normal atmospheric pressure, which doesn't have such a problem with X-rays due to much shorter mean free paths of charge carriers, hence far lower final energy of collision.

:) No, not a can crusher/ coin shrinker. Uh, well maybe I'll do one of those too, for fun. Still searching for a suitable impulse capacitor.

To Be Continued

At left, new items below the Spellman are a couple of vacuum ionization gauge controllers, and a pneumatics panel which will be used to drive things like air-actuated bellows valves. It also provides pressure regulation for inert gas used to fill the vacuum system via bleed valves when shutting down.

None of these are connected to anything yet, just put in place to get an idea of how things will fit, there and in behind them.

20150110 Saturday

The vibration mounts arrived a couple of days ago, and today I was planning to fit them to the pump. On the surface the mounts look fine, exactly as such mounts should look. As from the ebay listing.

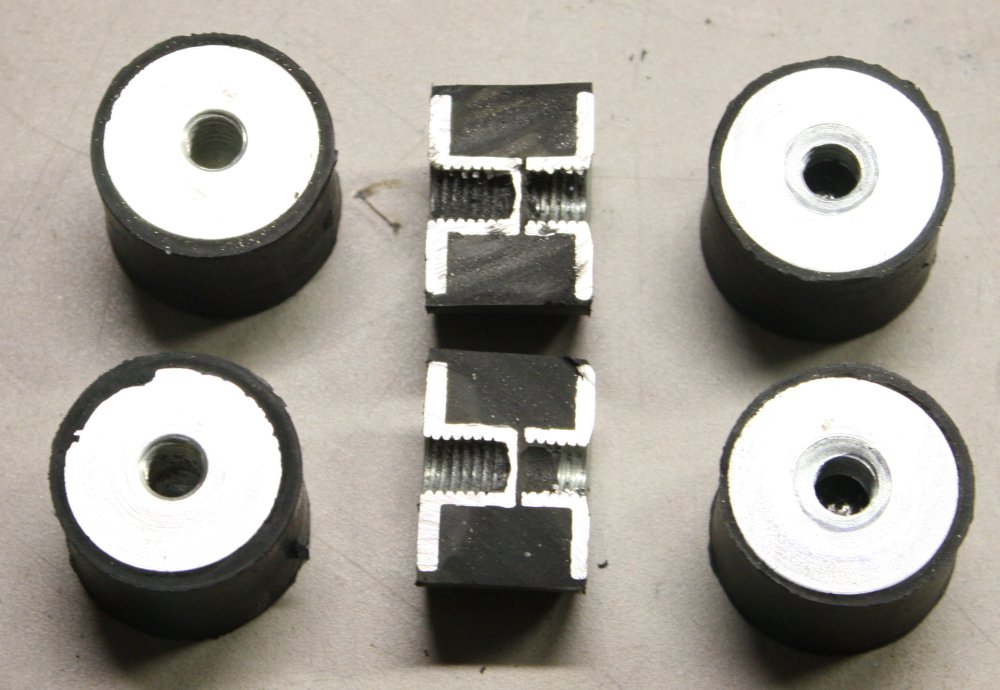

However on inspection they have a ridiculous flaw, that makes them useless. Such a stupid design fail! I don't think anyone would believe me if I just described it. So here is one of the mounts cut open to show the problem.

The whole point of a vibration isolator mount, is to allow one side to move a few mm in all directions, while the other side remains motionless. So the isolator is supposed to consist of two metal mounting plates with stud bolts or threaded holes, and between the metal plates a block of rubber that can flex in any direction.

But in these ones, the two metal parts are in contact inside the rubber. It's amazing. They only needed to be separated by about 4mm. Interestingly, that's how much they would be separated by if both metal parts were the same length as the short one in the cut open example.

My guess of how this happened, is that by design both end pieces were supposed to be cut short like in the cut open one. But somebody got lazy, and decided to reduce their effort. They only cut half the end pieces short, and carefully used one short and one long in each damper.

Terrific. It's not worth the postage cost to return them. But now I have to search again for a supplier of real vibration mounts. The seller refunded the total payment immediately when made aware of the defect, so they're OK. I wonder how many of those things they will now be returning to the manufacturer?

20150625 Thursday

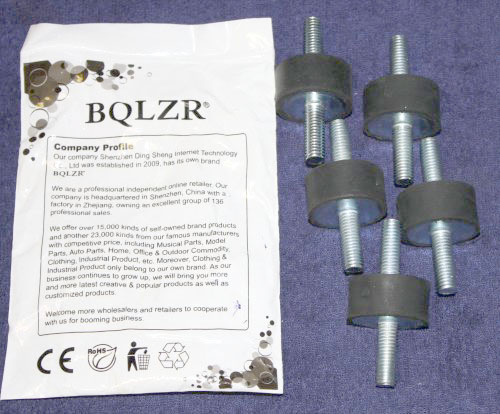

After a long gap, I finally found some cheap, usable vibration mounts. Ebay from China, of course. US$9.22 for 5, free postage. They arrived today. That's a curious brand name — BQLZR. Oh well, the important thing is their insides are all rubber, as opposed to touching metal bits. I verified this by squishing one in the vice.

After a long gap, I finally found some cheap, usable vibration mounts. Ebay from China, of course. US$9.22 for 5, free postage. They arrived today. That's a curious brand name — BQLZR. Oh well, the important thing is their insides are all rubber, as opposed to touching metal bits. I verified this by squishing one in the vice.

Yep, it's all rubber.

I wasn't able to find 20mm high ones, only 15mm high. Since there's not much clearance between the pump and the stand, 5mm spacers were required with these. No problem:

|

|

|

|

|

So that's the pump mounting done.