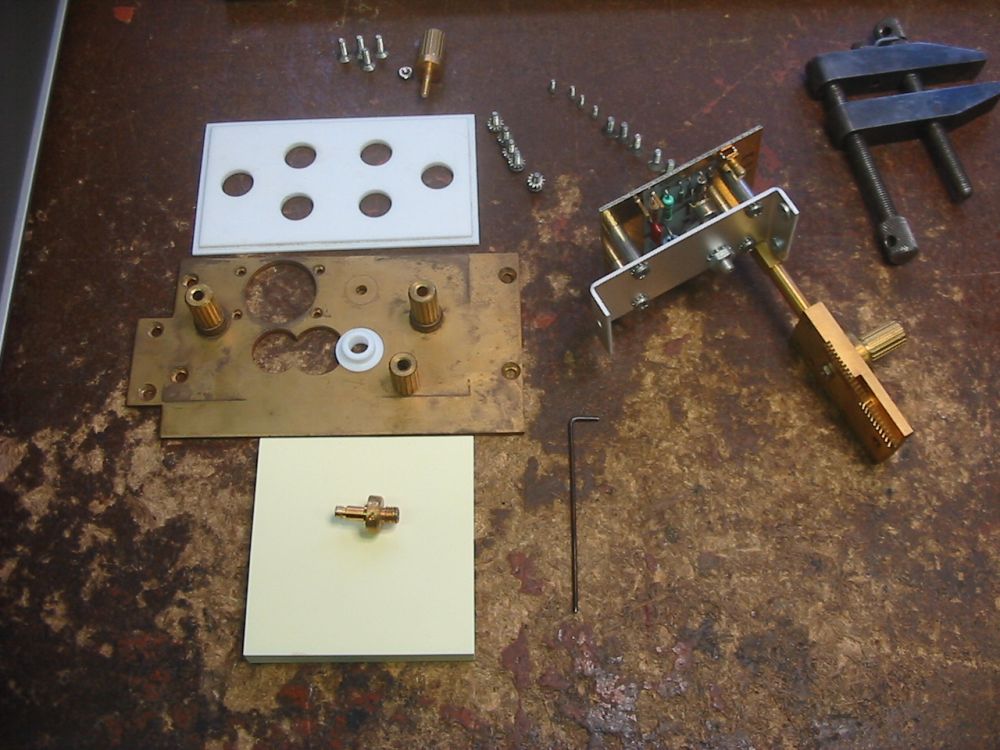

A photo from the ebay listing. Yes, I saw the tilted power switch button.

Those who know me are aware of my obsession with collecting and restoring old Hewlett Packard and Tektronix test gear. Theoretically I'm only interested in gear from the 1970s to early 1990s, that 'could be useful' for my assorted development projects. I rationalize this preference with the argument that during that period these manufacturers were run by engineers not lawyers, and so they produced excellent detailed operating and service manuals for their instruments. These included full schematics, theory of operation, diagnostic and calibration proceedures. You see engineers naturally understand that the owner of a piece of expensive test gear has a right to expect availability of everything necessary to maintain the equipment themselves. Whereas a 'suit' will immediately start calculating how much more profit they can make by forcing customers to rely on the manufacturer for all equipment servicing. Therefore, why should they make the service manuals publicly available? Besides, it's all proprietary information, and must be kept secret so their competitors can't just copy the products, right? Even better if they can build in deliberate operating restrictions and lifetime limits, requiring customers to pay for 'upgrades' and then buy a new one at some predictable time in the future.

And the 'suit' would be correct - if the only customers are corporations, that don't give much of a damn about operating costs; if you ignore that the technological advancement of the human race depends on individuals learning how to do things from others, and that human civilisation depends on material things lasting, so society as a whole isn't constantly struggling to replace 'planned obsolescence' failures. But that's a sidetrack I won't pursue here.

Anyway, technical equipment from before the '70s tends to be too old to be of much use for my purposes, while gear from after the early '90s is generally impossible for a financially constrained individual to maintain. Since, no service manuals available. Not to mention that it's too expensive in the first place.

Some time ago my collection reached a size where it's mostly adequate for my needs, and in fact is beginning to be more of a hinderance to 'real work' due to taking up so much space, and the long backlog of units that need repair and restoration, which takes time away from higher priority projects. So I cut my ebay buying habit right back, effectively to zero for larger units.

A couple of weeks ago an upcoming ebay auction set including a HP 34401A multimeter was brought to my attention by a post on the http://www.eevblog.com forum. Hmmm.... actually, I really should get at least one modern, precision multimeter, for calibration checks of older ones I have. Then I looked at the seller's other items.

Oh my goodness! He has an HP 4342A Q-meter for sale! And he's in Melbourne, Australia, so shipping would be cheap, plus there'd be much less chance of the instrument being damaged. It's a sad truth that maybe 20% of all my purchases from the USA got damaged in some way during shipping. Sometimes seriously.

The Q-meter really appeals to me because it's such a fundamental measurement, yet rather hard to actually do. Plus the instrument's design style is so unusual (for Hewlett Packard.) It's a very pretty piece of gear, and something I definitely want.

A photo from the ebay listing. Yes, I saw the tilted power switch button.

It also turns out he's selling a GRC precision variable capacitor as well, so that also goes on my 'want' list. I have a few pieces of GRC gear, and it's always beautifully engineered. Plus, this is useful as an accessory for the Q-meter.

The GRC variable capacitor. (Before I cleaned the front panel.)

There's a potential problem though. The ebay seller has almost no prior history. There's no way to get any idea of how reliable they are. This is a big worry when considering buying several hundred dollars worth of stuff from them.

In the end, I decided to take the risk. That Q-meter is worth it! And I might as well bid on a few other of his items as well. It's a long time since I bought myself something nice. I end up with this list, for bidsniping setup. In the order of auction endings:

A very good LCZ meter GR precision variable capacitor HP 34401A 4-wire multmeter An insulation tester HP 4342A Q-meter Bird RF Power analyst. An old Grid Dip meter. A 128A Lock-in Amplifier An old Leader oscilloscope (as a gift for a friend)

The first one ends around 11am Friday, and the others over the following half hour.

I haven't used my old bidsniper.auctionstealer.com service for years, so my account has long ago reverted to 'free, minimal service'. With over 30 hours till these items start to end, there should be no problem reactivating my account for a minimum interval. So I log in, and pay the small fee for a one month activation. The site claims activation should happen 'instantly'. Of course it doesn't happen instantly, or even in the next hour, so reading the fine print elsewhere it turns out to specify 'within 4 hours.'

That doesn't happen either, despite paypal showing the payment as having succeeded. Six hours later, still nothing. I send a message to customer support asking what's up, and go to bed.

The next day, still nothing. They seem to be ignoring both the payment and any queries I send, via any of the possible methods. I give up on them, start looking for alternate bid sniping services.

Turns out there are a lot of them now, unlike years ago. I recall that ebay bought up bidsniper.auctionstealer.com, so perhaps that one has become a walking undead zombie too, just like ebay. Anyway, one called https://www.bidnapper.com/ seems like a good deal, and they offer a free trial use. Enough for my purposes here, so I sign up.

It turns out bidnapper's service is much better than auctionstealer, so they have my business from now on. I set up my list of auction numbers and bid limits. Fingers crossed that bidnapper actually works, when the 'last 5 seconds' comes.

In the meantime I place a recovery claim with paypal, to get back my $12 from auctionstealer, who still have not responded to anything. False advertising, non-provision of advertised service, unresponsive. Yep, they've gone totally ebay-ish.

Friday morning I almost decided to sleep in. Woke up, think 'hmm.. no urgent chores today, why not go back to sleep?' A little later, just before actually dozing off - 'Oh! Wait, the auctions!' Got set up to watch the process in plenty of time. This is when I discovered how neat bidnapper's bidding status page is. Really a very cool example of dynamic html. I'd placed bid limits on the probably high priced LCZ and HP multimeter that would only win if the competition wasn't too great, and they went for relatively low prices. Because I don't really need these things. On the other hand by now I've developed a severe case of 'HP Q-meter want', so I decide that I'll transfer bid weights across to the Q-meter from other losing bids. Since, that total was what I was prepared to spend anyway.

A little later and I've won the Q-meter and GR precision capacitor. Also the Lock-in Amplifier, cheaply enough to justify on the grounds that I'm curious to play with it, though it might be a devil to find a manual for. I'd already found and downloaded a manual for the Q-meter, however getting a physical original is now on my to do list. Fold-out schematics just don't work with pdf documents.

The LCZ meter and HP multimeter were heavily bid, but still went for pretty good prices. Just more than I wanted to spend.

http://www.ebay.com/itm/s/130843933052 HP multim. AU $430.00 snipes: 280 --> 430 http://www.ebay.com/itm/s/130843930315 LCZ AU $405.00 snipes: 265 --> 405 http://www.ebay.com/itm/s/130843935249 Q meter AU $355.00 snipes: 255 --> 355 http://www.ebay.com/itm/s/130843931081 GR precise cap AU $108.50 snipes: 52 --> 108 http://www.ebay.com/itm/s/130843940154 lock-in amp AU $64.57 snipes: 37 --> 64

About six hours after the auctions, I finally get an email from auctionstealer saying "sorry, glitch in system, your account is now activated and we gave you some extra time." I replied "Too late, forget it, please return my payment, I won't be using your service again." They did, the payment went back to paypal, who froze the money 'pending investigation.' Ha ha ha... all so typical. I wish there were good alternatives to those bastards at Paypal too.

And so now.... the shipping. The seller hasn't listed any postage rates, and there should be an 'all in one' option anyway. I send an ebay question asking what shipment options he has. Also, since I might be going to Melbourne around 7th March, if there's any chance of waiting till then to pick it up in person. And one more thing - since he'd said the items were being sold to make space due to a move, did that mean they were previously in use and in that case, did he still have the manuals for them? Would he sell them?

It turns out it's a largish company, just disposing of some surplus test gear on ebay before moving premises. Sigh.... I know what this means. And yep... Paraphrasing, "Oh sorry, we probably had the manuals, but we've been disposing of lots of stuff. They're probably gone." I checked, and yes, by 'disposing' he meant binning. Sigh. Why does this give me deja vu? Again?

The seller hadn't replied to the first question I sent him on Friday. But did reply well to later ones next Monday. In that first one I'd mentioned that I was worried about the fragile banana posts sticking up from the top of the Q-meter, and asking if he could be sure to pack it so they didn't get broken during the parcel tossing that always happens during transport. I felt a bit guilty about even mentioning this, since it's such an obvious matter. I didn't mention it again. I wish I had.

We decided the best thing was to send the one box via TNT, for quite a reasonable cost - just $32 Melbourne to my door in Sydney, with tracking. He sent them on the 13th, they arrived here on the 14th. Cool! The TNT courier had one of those electronic data entry things, which you're supposed to 'sign' on a touchscreen with a stylus. I have no idea how anyone thinks those things in any way capture acceptable signatures. They just simply don't. You sign, the result is a series of jaggy lines due to a way-too-slow sample rate. Well whatever, just another small example of mass technological delusion, no point worrying about it.

And now the unwrapping. This is always the best moment - except when it isn't.

The Box. It's been around.

It's pretty battered looking, but it looked like it was a reused box, with a lot of the corner rounding etc being from previous travels. Opening it (from the top), the thin rack mountable Lock-in Amp is on top, among an assortment of styro chips, foam blocks and bubble-pack. Very much re-used packing materials, but that's no problem as long as common sense is used. I remove the Lock-in Amp, and.... whut? Now I'm looking at the underside of the Q-meter. It's been put in upside down for some reason. Ok... The GR variable cap is off to the side, wrapped in a couple of layers of bubble wrap. I pull it out; it seems like it's OK. That leaves just the Q-meter, among the mixed packing materials. I hope it's OK like the others...

Pulling it out, the first thing I see is the bottom of the cardboard box. With a neat pattern of crush marks that obviously match the arrangement of the banana posts on top of the Q-meter. Twice.

"Are those marks...?"

"Yes, they are."

Oh oh... sinking feeling. How the heck did the banana posts come in contact with the box? Surely there'd have been some blocks of foam or something....

Nope. Whoever packed this apparently just sprinkled a few styro foam chips in, then put the Q-meter in upside down. So it was effectively resting most of its weight on the banana posts. Plus the weight of the Lock-in Amp.

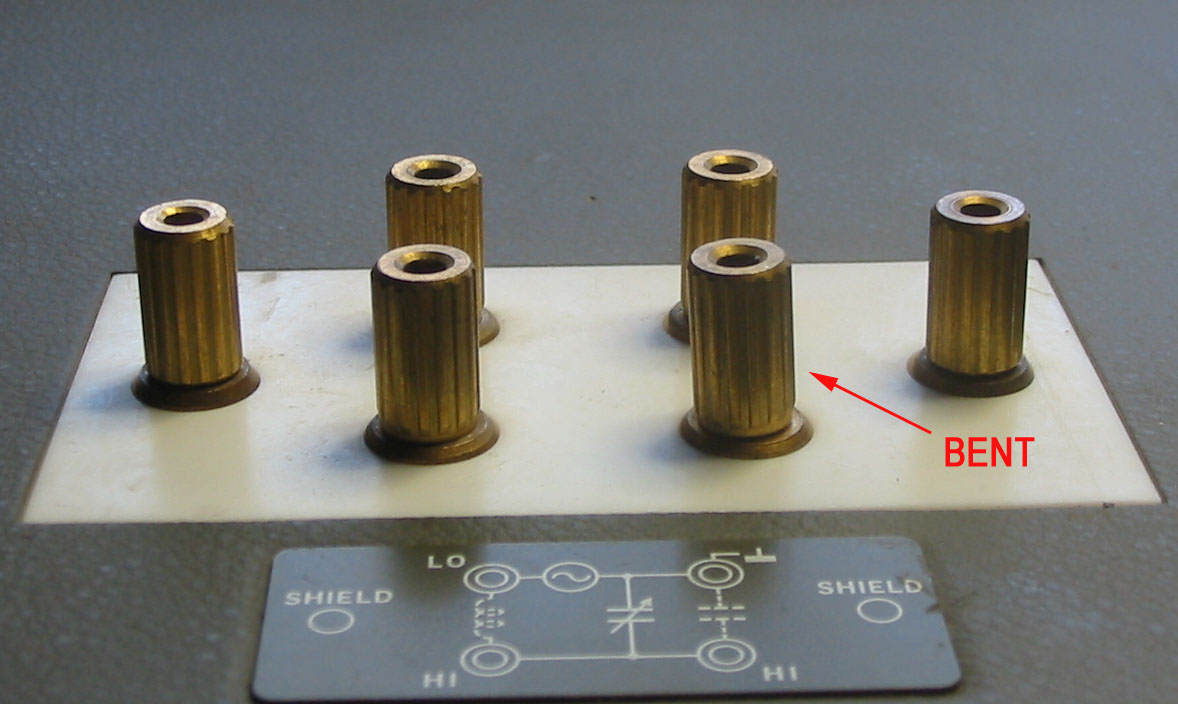

I'm afraid to look.... But can't not look. Turning the Q-meter over, for a moment there's great relief. It looks like the posts are all intact. Oh... but wait, is that one bent? Sigh. Yes, it is bent. Not a lot, just enough that it's too much to ignore. And I know the structure of those. Thin threaded brass tube, that will be virtually impossible to straighten without it breaking.

The bent post. Bent in post.

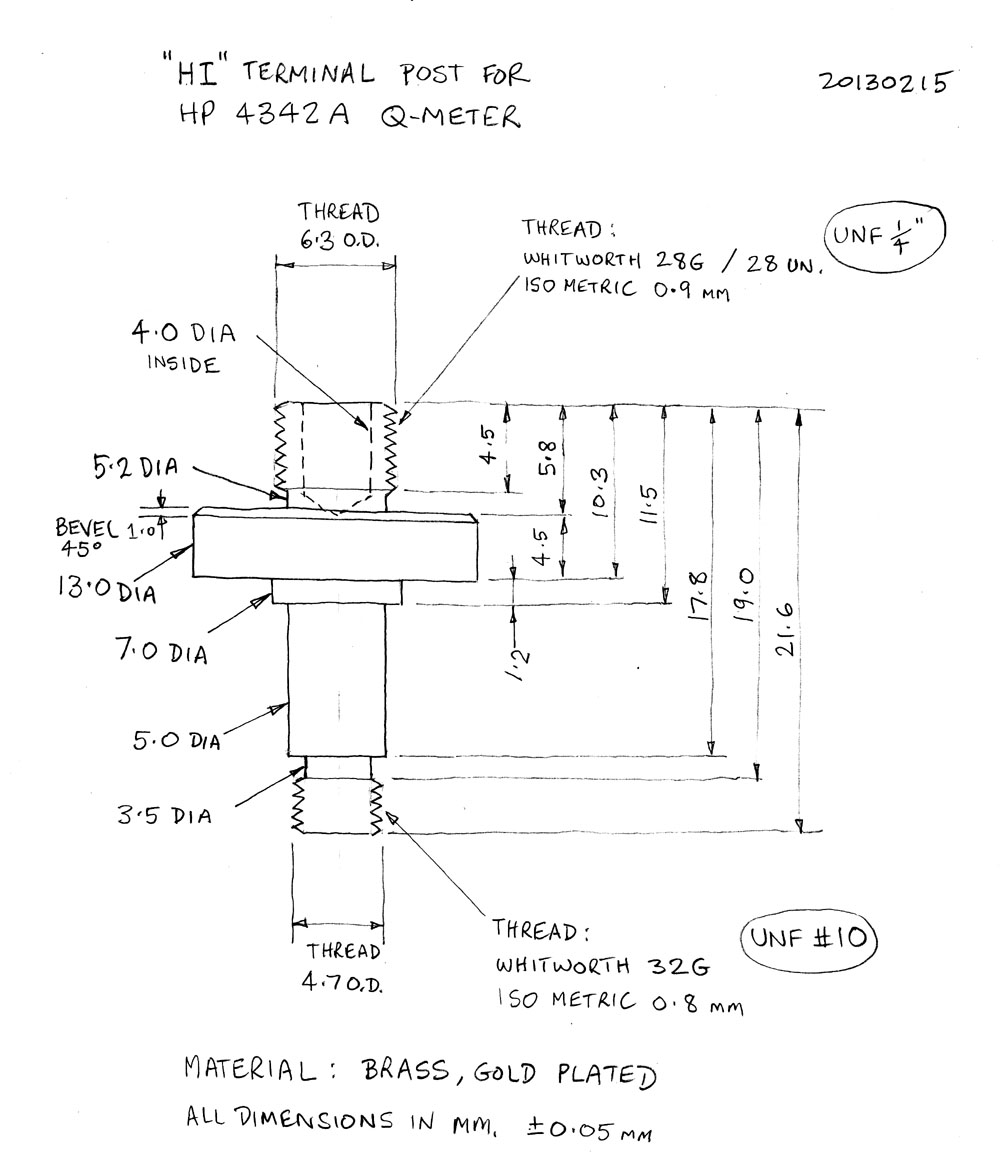

Well, that's very disappointing. Chances of getting a replacement part for this post anywhere, or from HP/Agilent - nil. It's not a standard banana post, it's a special gold-plated, custom machined unit just for this instrument. It later turns out that even the individual posts on the Q-meter are different. The bent one has only one the same. Not that this helps.

How incredibly annoying! The damage is small, but completely unacceptable, and will be extremely hard to repair. The very best option would be to just find another whole but not-working unit, and use it for spares. But chances of finding another in Australia are approximately zero point zero. And shipping from the US would be at least a hundred dollars, more likely two hundred. Meanwhile, the damage is entirely due to completely imbecilic packing. The person that did this was a total moron. It's not the worst case of stupid packing I've ever encountered, but it's pretty bad. (The worst was a US seller who placed a Tektronix 7000-series rackmount scope in a considerably larger box, and sent it to Australia with absolutely no other packing materials inside. Result - badly trashed scope.)

I send the seller an email describing the situation, and mentioning I'd delay giving him a negative feedback till I figured out if the connection post could be repaired.

In his reply he claimed the packing was done by a junior employee, who 'would be dealt with.' But made no offer of recompense. Terrific.

The 4342A Q-Meter. (Yes, bad photo. They are all bad photos. I was in a rush.)

The Line button cap is broken, but repairable. I'd noticed it was crooked in the original listing.

From the side. Did HP ever produce any other instruments with that front wedge shape and edge roller-knobs?

Rear view. It's nice to find BNCs with protective dust covers.

'Macservice'?

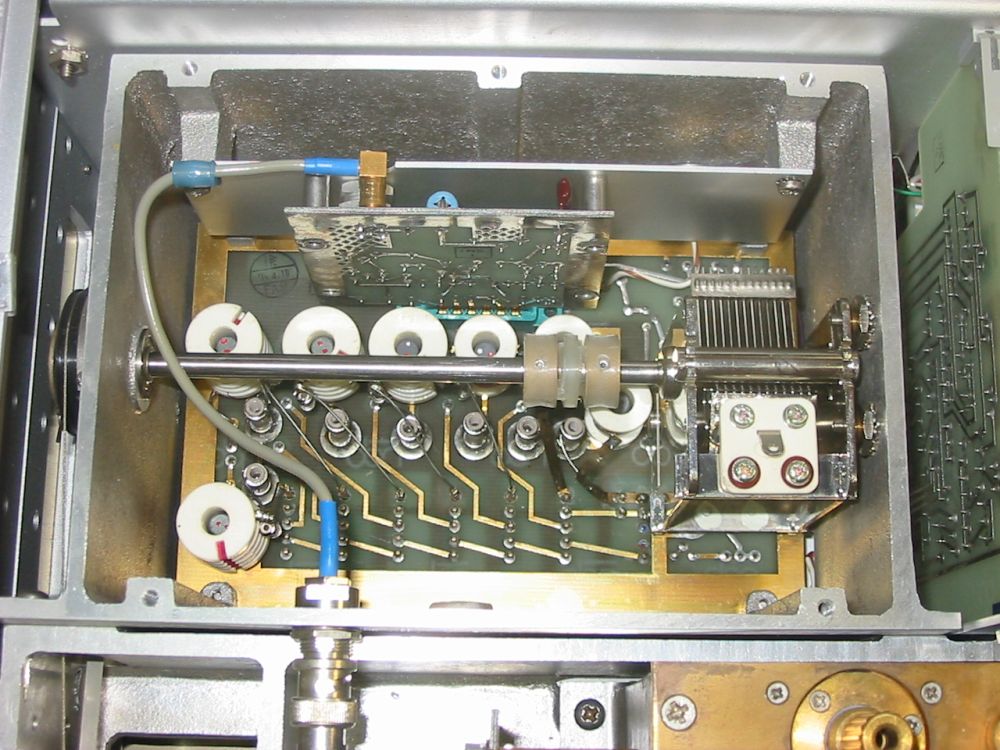

Top cover removed. It's very clean inside, thanks to the absense of any ventilation holes.

While moving it around I had noticed the sound of something small rattling around inside. No sign of it yet.

It's a bit sad that HP skimped on the thickness of the gold plating, so now it's more like tarnished brass.

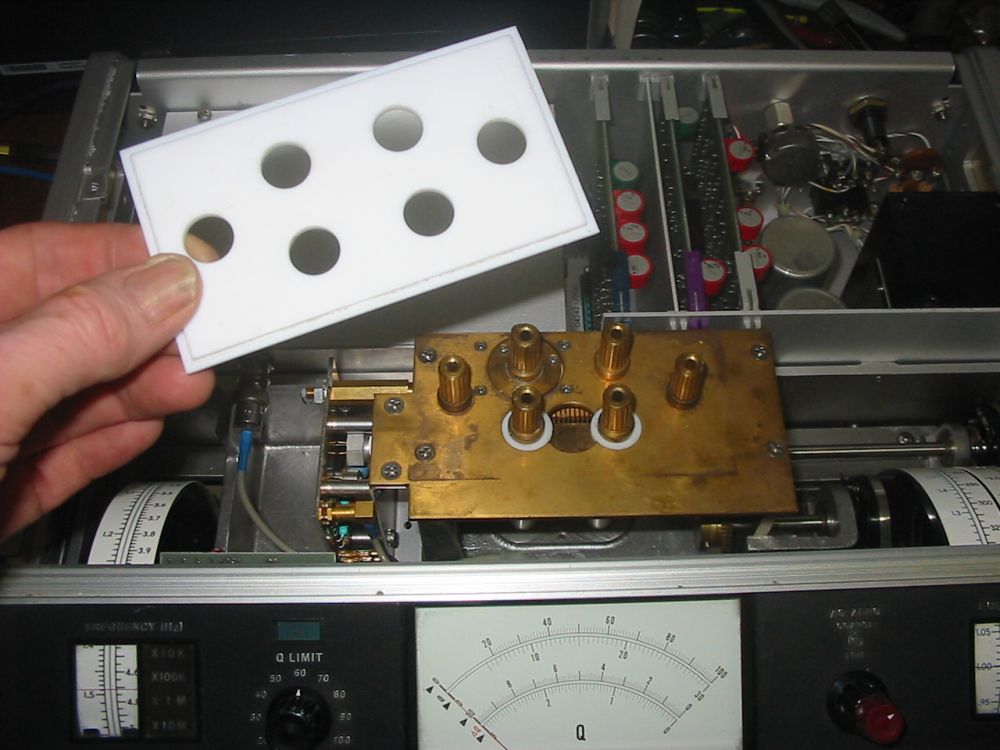

The insulating plate is machined teflon.

Three PCBs from R to L: Power supply, Limit detector, DC amplifier.

Not a single IC in sight. The two TO3 transistors are venerable 2N3055.

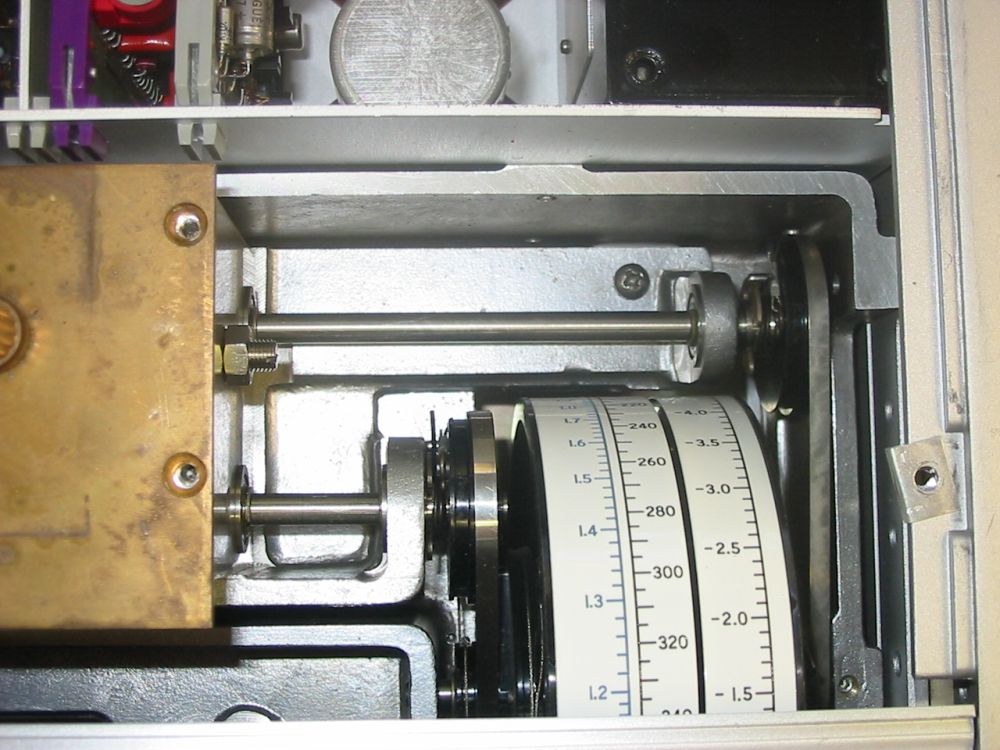

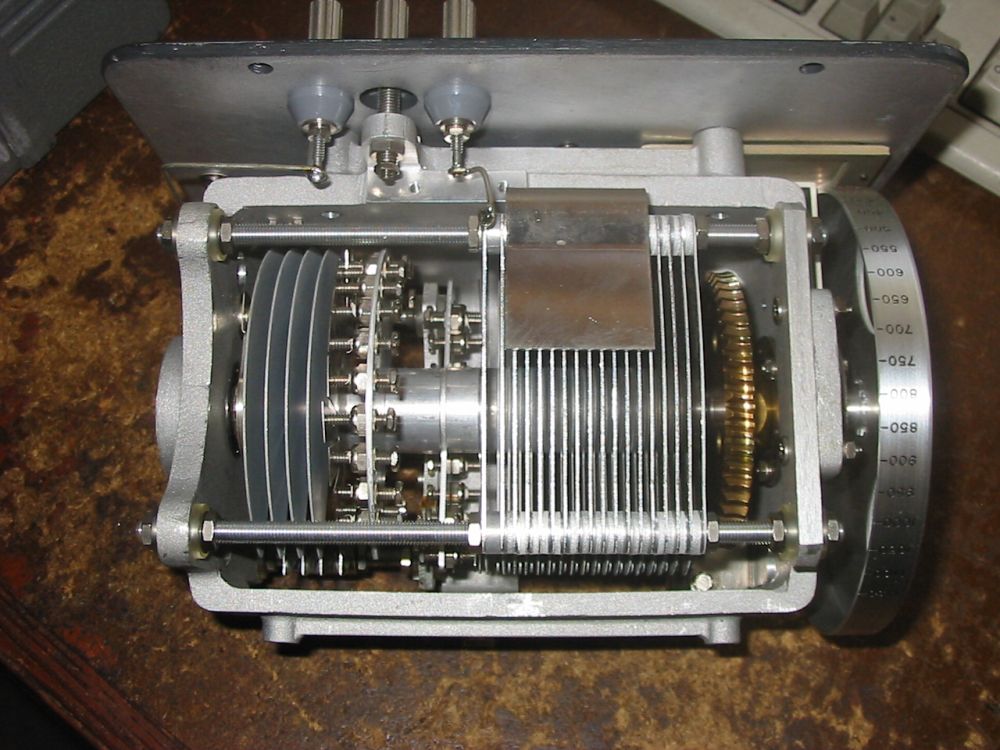

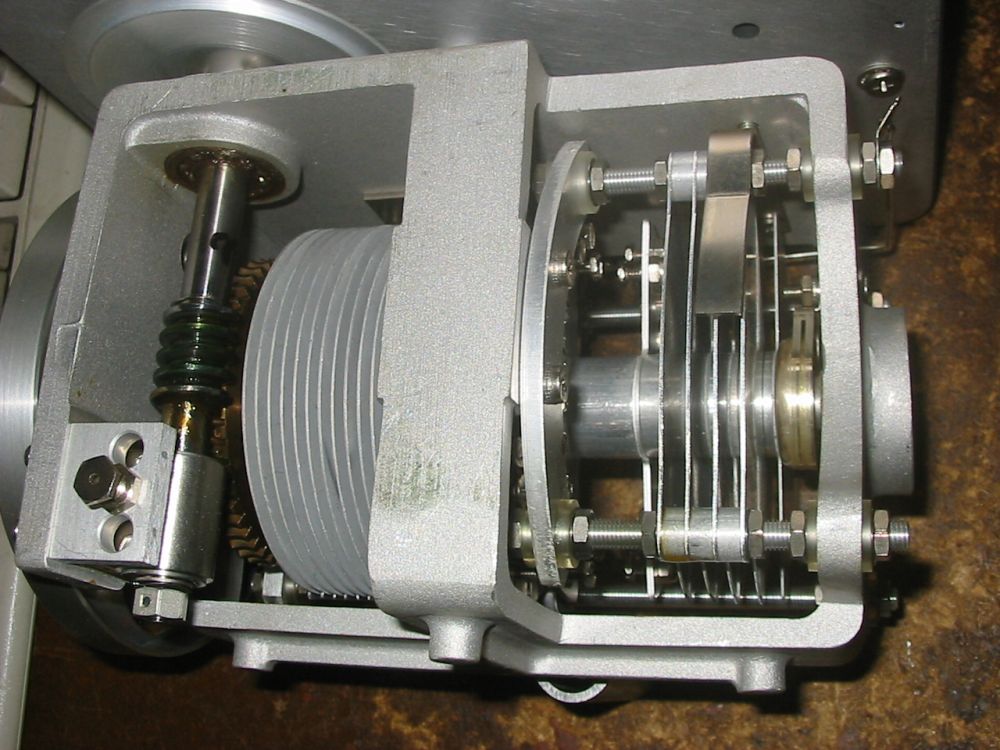

The 7 range oscillator. Switching is done via mechanical linkages from the front panel, and the vane capacitor is mechanically linked to the left hand roller knob.

All adjustment links are zero-play, and feel really nice to the touch.

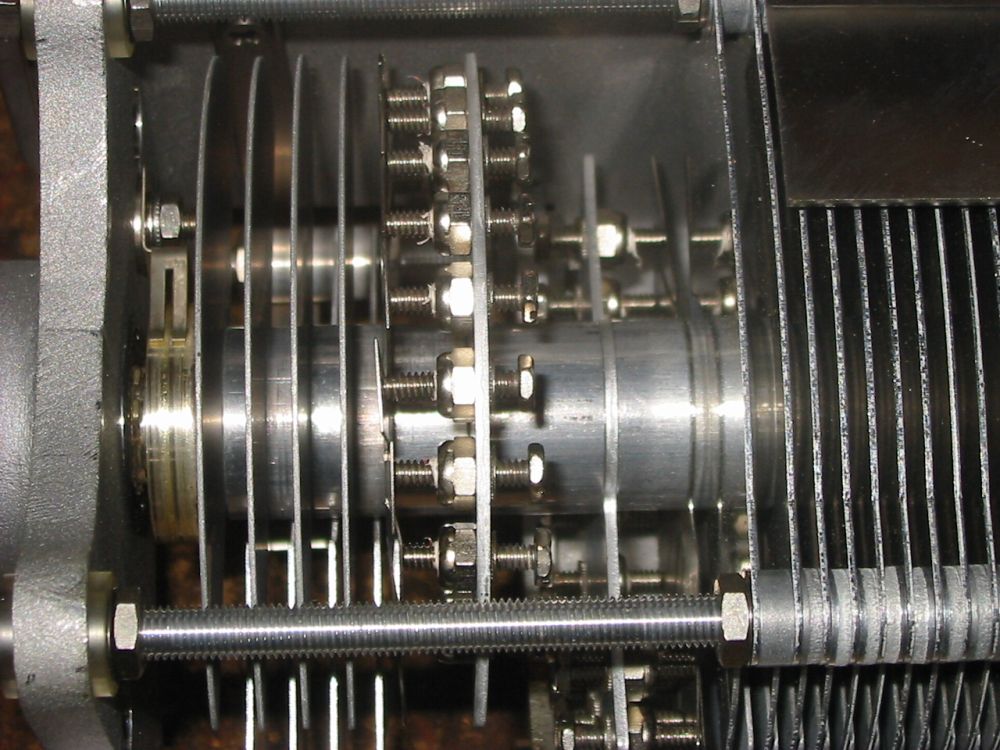

Linkages to the vane capacitor under the connection posts. There's more mechanics in this thing than electronics. It's rather nice to look at, but I wouldn't want to have to disassemble this stuff and then get it back together with the indicator dials still in calibration. Fingers crossed it isn't necessary.

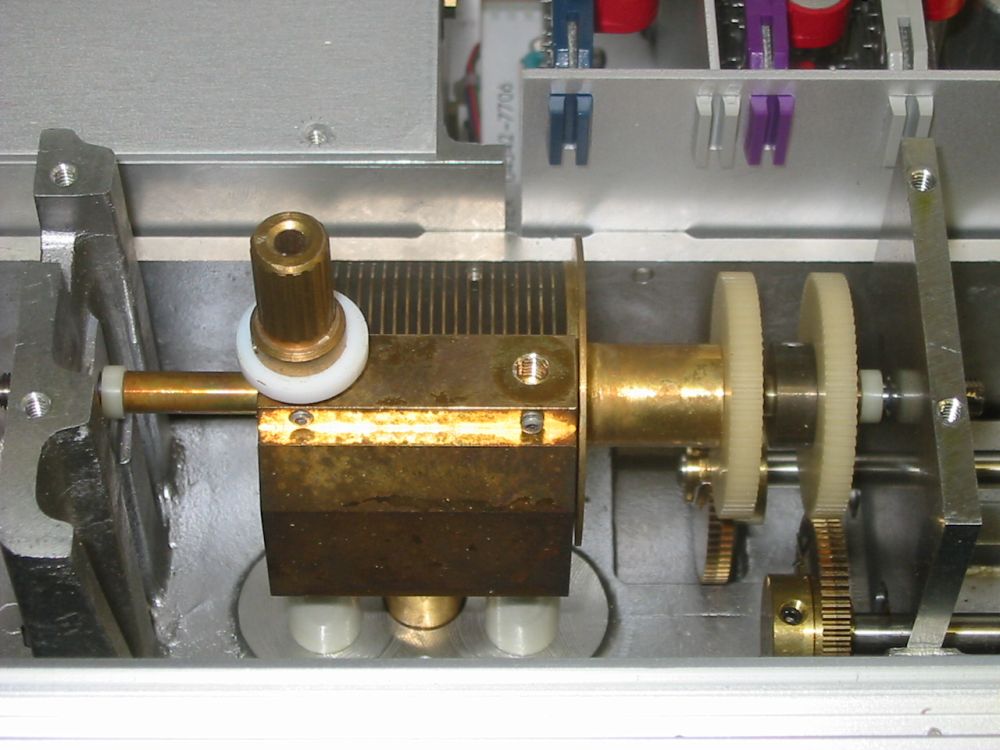

The connection fixture removed. Much to my relief the solid plate has not been bent by the shipping impacts. So the only damage so far is the bent post mount sitting on the post-it notes. (I later discovered one of the outer 'shield' posts is also slightly bent.)

The fine finger springs on the part at right contact each of the individual vanes of the adjustable capacitor underneath the fixture.

Bent. Too bad I didn't get a decent photo of it. Even blurry you can see how bent it is.

The outer shell of the variable capacitor is a very solid block of brass, and fortunately the porcelain standoffs it's mounted on didn't break either. It's looking like HP designed the thin upper screw section of the mounting posts as a kind of damage-limiting failure point. Under impact the posts would break off, while the internals of the machine should survive.

The bent post mounted in a lathe. I'd machined down the end of the metal rod to a good fit in the hole in the end of the post. So the rod is axial with the end part of the post. That's how bent the post is.

I knew if I just tried bending the post back it would definitely break, as it's brass and the walls at the base of the bent part are very thin. The plan at this point is to try applying light 45 degree tangential blows to the end of the rod, so the brass walls of the post are nowhere subjected to tension, only compression. The aim is to re-compress the side that got stretched, while not tensioning the other side (because it would fracture.)

Nice plan. Didn't work.

Well it almost worked. The post was almost straight, although the tapping pressure was also slightly compressing the post end, making the threads a little under-pitch, so the knurled cap is a noticably tighter fit. Then right at the last moment, the 'pushing' suddenly got a lot easier. It was straight (see 'after' video), but.... looking at it under a magnifying glass there's a hairline fracture that runs about half way round the circumference. So it's holding together for now, but will break off completely at some time as the post terminal is screwed and unscrewed.

So now, it absolutely has to be replaced.

Dammit.

The top plate, buffed up.

The underside. At this point I found the 'rattling loose object'. It was a small screw, and for a while I was looking for where it could have come loose from. Nothing... and it's a steel, chrome plated M3 screw, while all fasteners in the Q-meter are stainless UNF. It so much doesn't match that I'm certain it must have been accidentally dropped into the machine some time when the cover was off. Since there's no ventilation holes, there's no other way it could have got in there. Mysterious.

Linkages from the frequency range buttons, to the oscillator range switches.

It's simple, it works, and the buttons have an interesting long travel and solid 'clunk' feel when pressed.

Wiring, done in the days when people cared to make wiring look neat.

Video 1

AVI file. The bent post rotating in a lathe, showing how off center it is.

Video 2

After straightening, rotating with the knurled top. Looks good, except it's fractured half way through.

Well, looks like I'll be attempting to make one of these, then get it gold plated.

Should be able to do this, though I don't trust my minimal lathe thread cutting ability, so that's two thread dies I'll need to buy. If they were metric I'd already have them. But nooooo... They are American UNF threads.

How ironic. I like this old gear because it's almost all simple electronic components that are easy to get, and can almost always be substituted if there's a problem getting exactly the right part. But here I am needing to source a unique mechanical part instead.

Oh well.

Update - Repairing the Q-Meter

Update 2 - I ended up giving the seller a negative feedback. Here's the whole exchange.

The face. This is after cleaning. No bent banana posts here!

In the rectangle under "Serial 3307" something was once glued on. I wonder what it was.

The chief function of the large clear plastic disk appears to be decorative, though it also contributes inertia when spinning the dial. Maybe that's the purpose? Anyway, it's pretty.

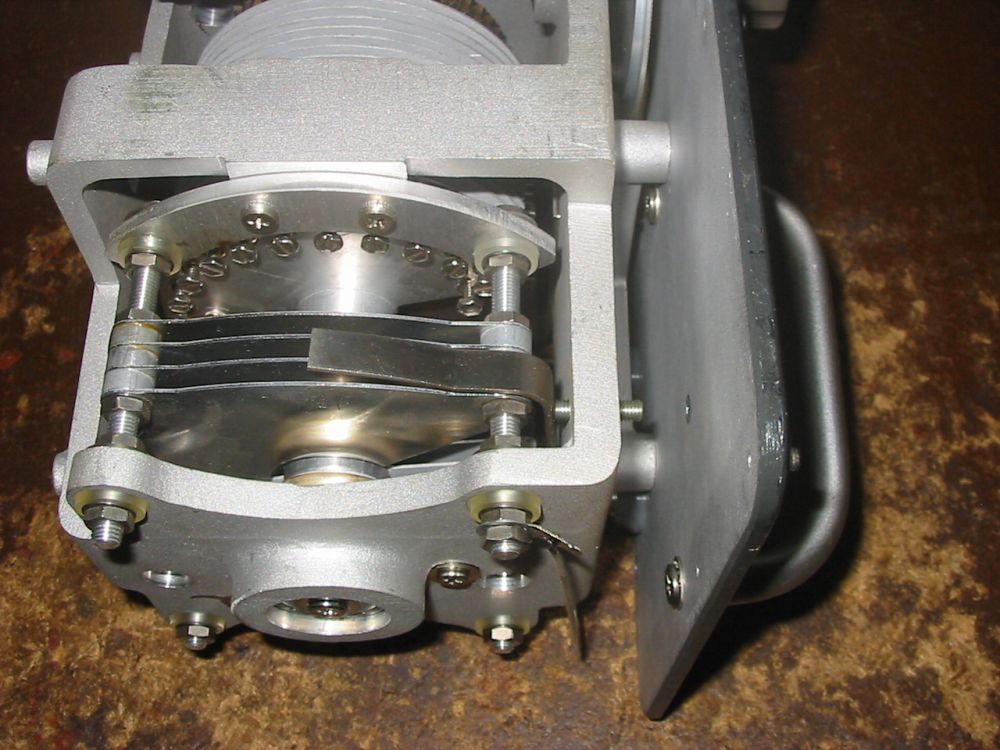

There are two electrically separate capacitors. One ten times the value of the smaller. Large one on the right here. Both have a 'profile adjustment' via multiple screws that warp small segments on one of the vanes. This is very much 'don't touch' territory.

Closeup of the adjustment vanes.

The worm gear on the underside.

The lower decade cap, like the upper decade, has an 'offset' adjustment metal strip with screw adjustment of its proximity to the 'hot side' capacitor plates.

Solid case is solid.

Well that's gratifying. After calibrating the LCR meter zero with its leads in exactly that position but not connected to the GR unit, then connecting them, they agree perfectly.