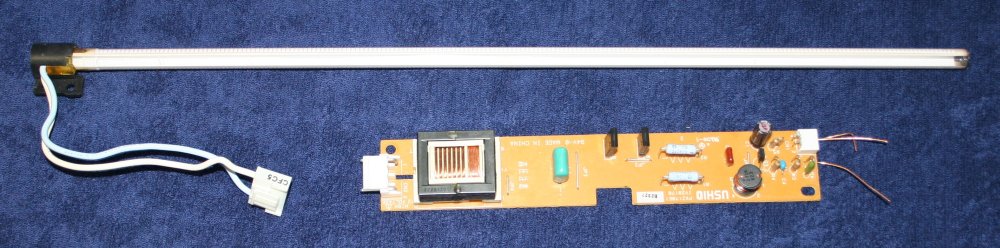

Back in May I dismantled an old photocopier. Since then I've been busy with a bit of a workshop upgrade and other things, so assorted minor projects lay neglected. Now I'm done with that, and cleaning up the detritus of small jobs that accumulated in the last two months. One piece of junk that floated to the surface, was the scanner light unit from that photocopier. Discarding the plastic moulding, this is what's left:

The bits of copper wire are my addition, to connect power to it. There's a third on/off control line, that enables the inverter when pulled to the negative power rail.

"Oh, a small fluorescent tube and inverter, so what?" you think, right?

That's what I thought at first, and nearly tossed this thing in a box of mixed small fluoro tubes out of laptop LCD screens and such. Then I noticed the odd patterned electrodes along the glass tube. "But... those are on the outside of the glass?!"

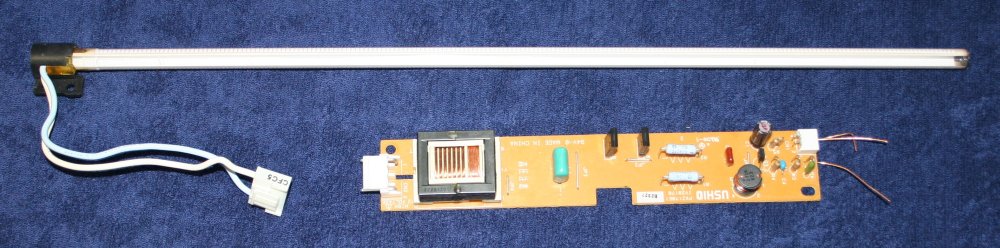

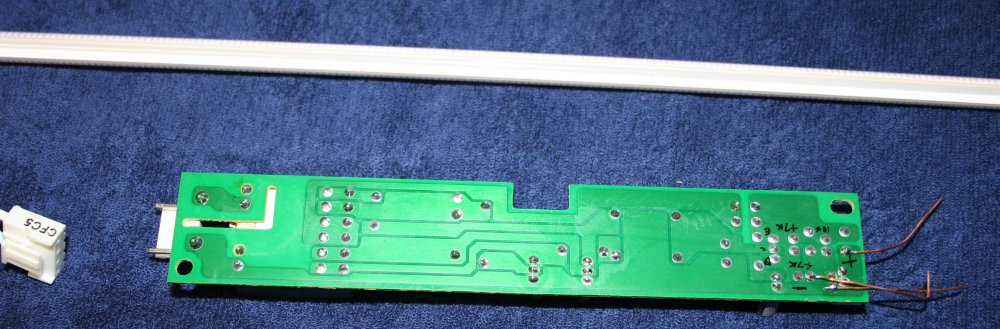

In fact they are not even on the glass. These electrodes are a metalized pattern on thin plastic films held against the glass by an outer final layer of clear heatshrink tubing. There appear to be at least three layers of plastic film, with the inner two having slight variations of the electrode pattern along their length. Presumably to achieve a slightly adjusted profile of the tube's light output over the length, to optimize the copier's reproduction accuracy.

At one end the wires from the inverter board make contact with the plastic film metalization like this:

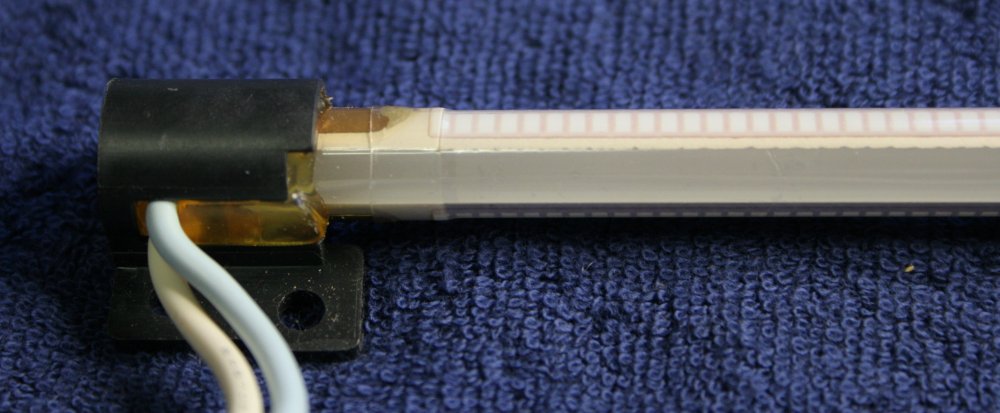

That clear apperture runs all along one side. The far end is just an end, and there's a film of white material on the inside surface of the glass with the same aperture along one side. Right at the end there's what appears to be a thin line of metalisation on the inside of the glass, that just bridges the apperture gap, but does not go all the way round inside the tube.

And no, after examining the thing carefully, there's no conductive penetration of the glass envelope anywhere. This is not a normal fluorescent tube. No hot filament or cold cathode electrodes at all.

Yet it lights up very brightly. The inverter draws about half an amp at 12VDC and the lamp lights with no perceptible delay from application of power to the inverter. The illumination comes from the inner layer of phosphor, not the inside volume of the tube, so it isn't anything like a neon light. The small inner metalization strip is very visible at the right here.

Can you see how the tube works?

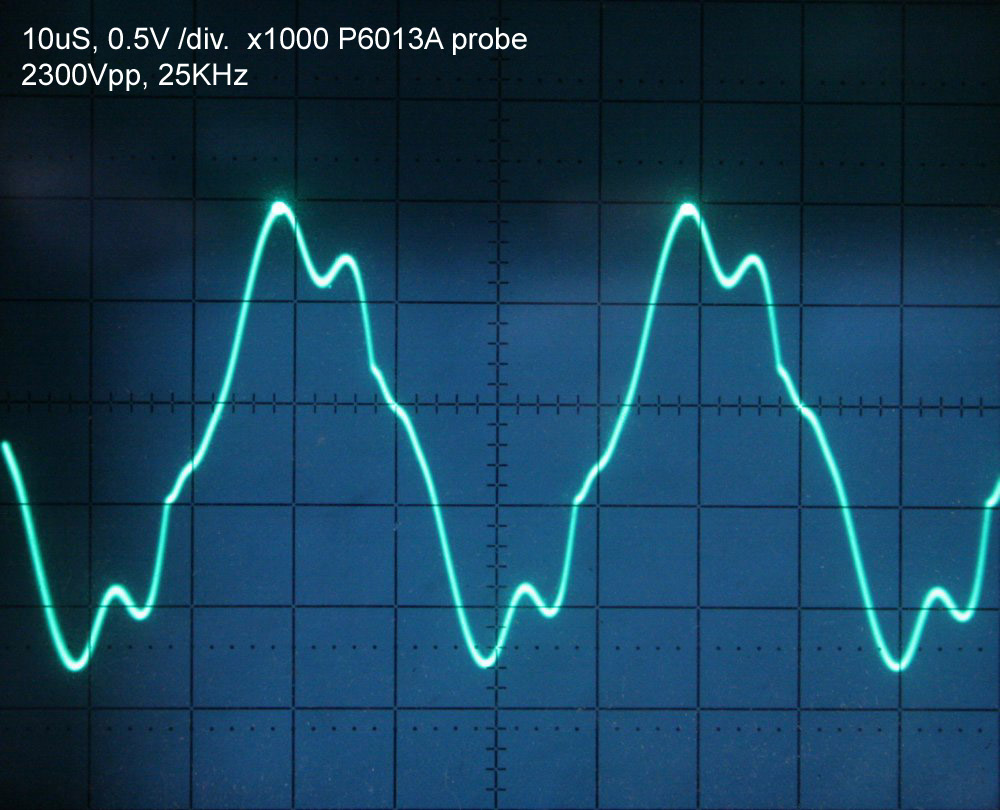

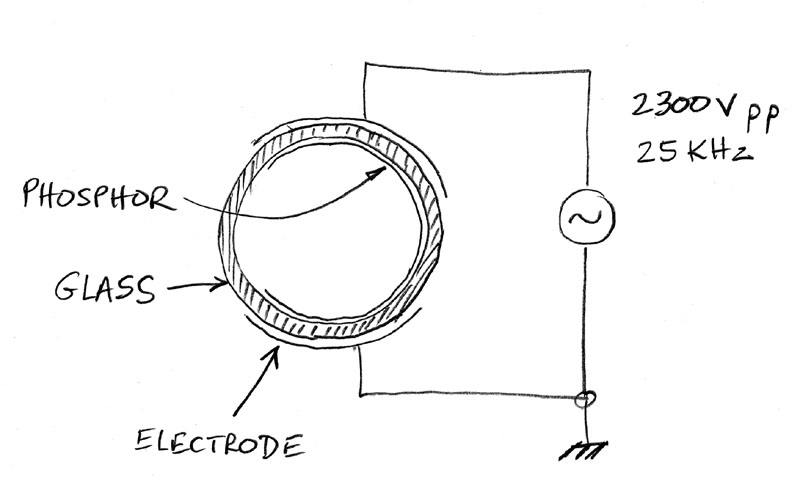

Considering the segmented secondary winding on the inverter transformer, and the anti-creepage slotting of the PCB around the HV output, I figured the output would be over 1000 VAC. Not something to poke a standard scope probe into. So the probe above is a Tektronix P6103A, that divides by 1000 and can take up to 12 KV safely.

The other wire to the tube is at DC ground.

The HV waveform to the tube. Minor ripples are not significant; all that matters is there's about 2300 Volts peak-to-peak, 25 KHz AC between those metalizations along the outside of the tube. Definitely a NO TOUCH — it would kill you.

I think this light is rather clever. It's fundamentally a Cathode Ray Tube, producing light by bombarding a phosphor layer with electrons. The electrons are stripped from the atoms of a low pressure gas inside the tube by the high electrostatic field induced by the electrodes outside the glass. The excitation signal is AC, so the fact that the glass is an insulator doesn't matter. Electrons just get thrown back and forth inside the tube, accellerated enough in that short distance to make the phosphor elements glow when impacted.

The beauty of this is that there are no metal electrodes to burn out or outgass, no metal to glass seals to potentially leak outside air into the tube, and manufacture is very simple. I'd expect this tube to have a very long operating lifetime, which really only depends on the durability of the phosphor coating.

Some more discussion on eevblog: http://www.eevblog.com/forum/projects/an-interesting-illuminator-from-an-old-photocopier.

Including a mention of something close but not quite the same — the EEFL, or End-Cap Type External Electrode Fluorescent Lamp.

This is one reason I like taking things apart. Usually there's something new to learn from it.

It's kind of sad that most people just toss their unwanted technological trinkets, without any interest in seeing the innards and at least making some attempt to understand how they work and how they were made.